Dual-purpose numerical control processing machine tool for outer circle and spiral slot of rice-milling sand roller

A technology for CNC machining of machine tools and spiral grooves, which is applied in metal processing mechanical parts, metal processing equipment, tools for lathes, etc., can solve the problems of large machining errors, waste of manpower, poor machining accuracy, etc., and achieves the requirements of improving machining accuracy. , The effect of improving production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

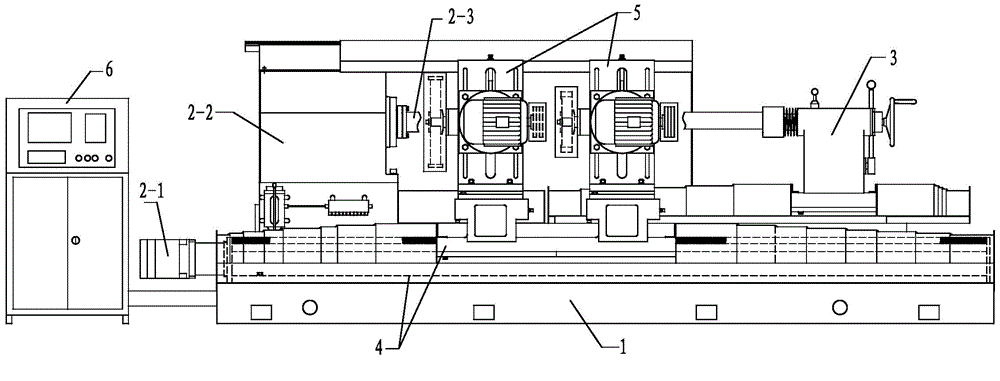

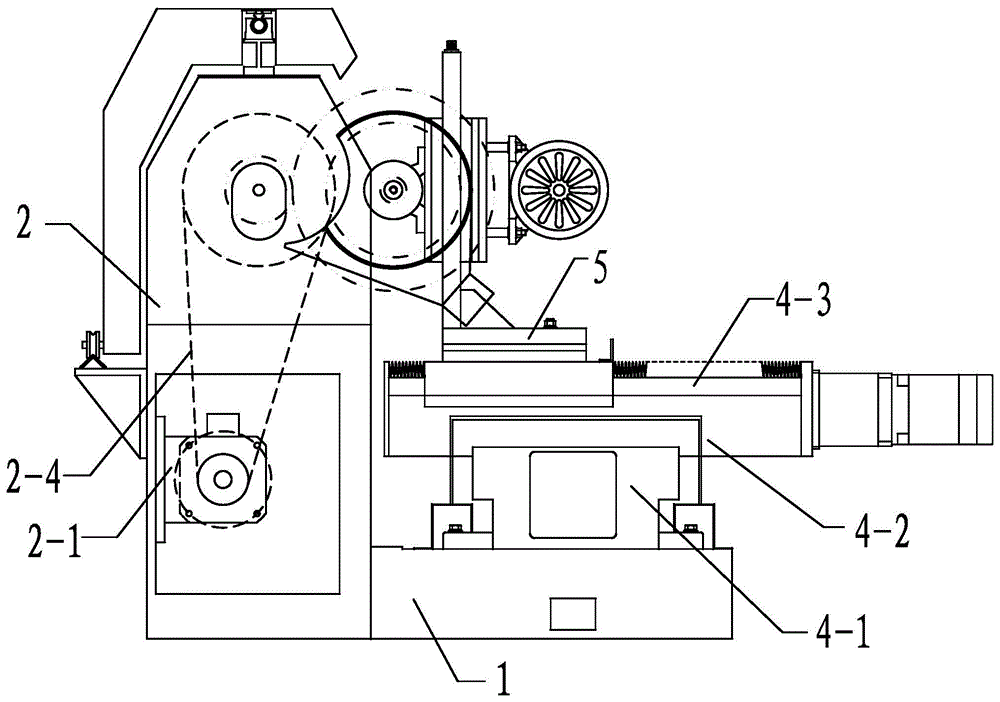

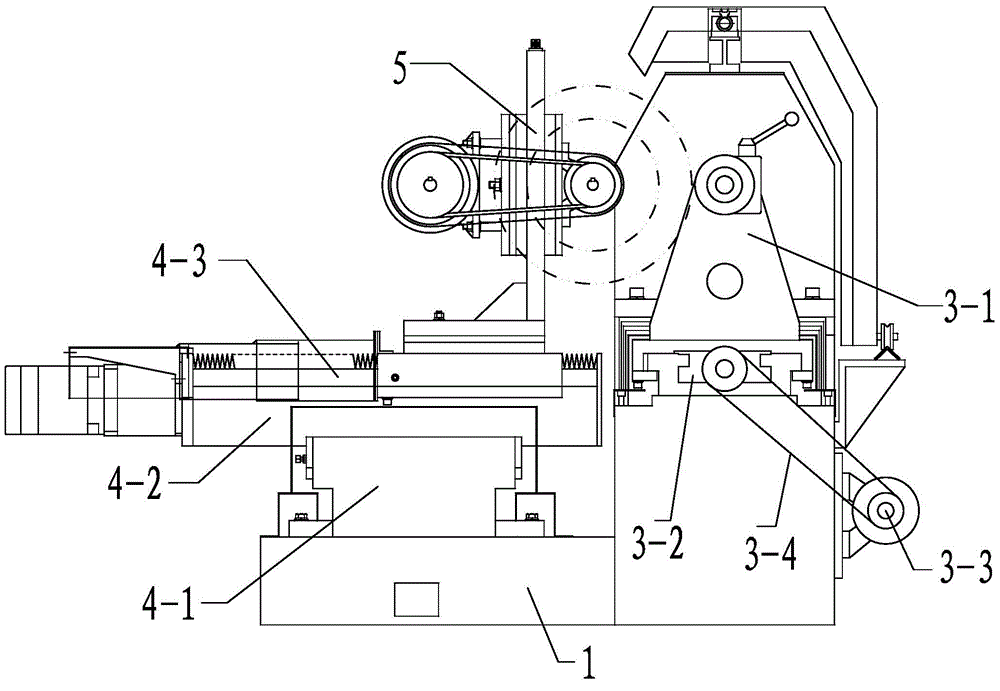

[0037] The present invention will be further described below in conjunction with the accompanying drawings. like Figure 1 to Figure 4 A dual-purpose CNC machining machine tool for the outer circle and spiral groove of the rice milling emery roller shown, including a machine base 1, a spindle box part 2 arranged on the machine base, a tailstock part 3, a tool rest part 5 and a feed part 4 , it is characterized in that: the spindle box part 2 includes a spindle servo motor 2-1, a spindle housing 2-2, a spindle 2-3 and a transmission mechanism 2-4 connecting the spindle servo motor and the spindle, wherein the transmission mechanism 2-4 Including the main shaft reducer 2-5 and the synchronous toothed belt 2-6, the main shaft servo motor 2-1 is connected to the main shaft through the main shaft reducer 2-5 and the synchronous toothed belt 2-6, and the main shaft servo motor 2-1 The speed of the main shaft can be adjusted by stepless speed change, and the appropriate speed can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com