Double-horizontal-shaft continuous stirrer with oppositely arranged inner and outer stirring units

The technology of a stirring device and twin horizontal shafts is applied in the field of stabilized soil material mixers, which can solve the problems of reducing the rigidity of the mixing shaft, worsening the throwing effect, and unfavorable uniform stirring of the stabilized soil material, so as to improve the mixing uniformity and prolong the mixing time. , Improve the effect of the shaft holding phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

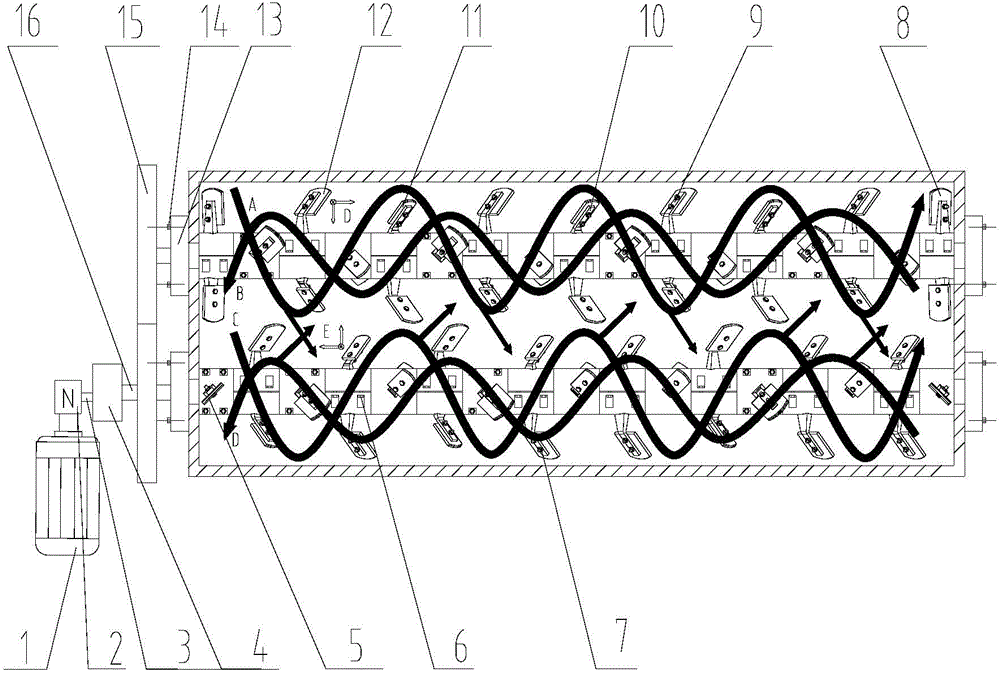

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

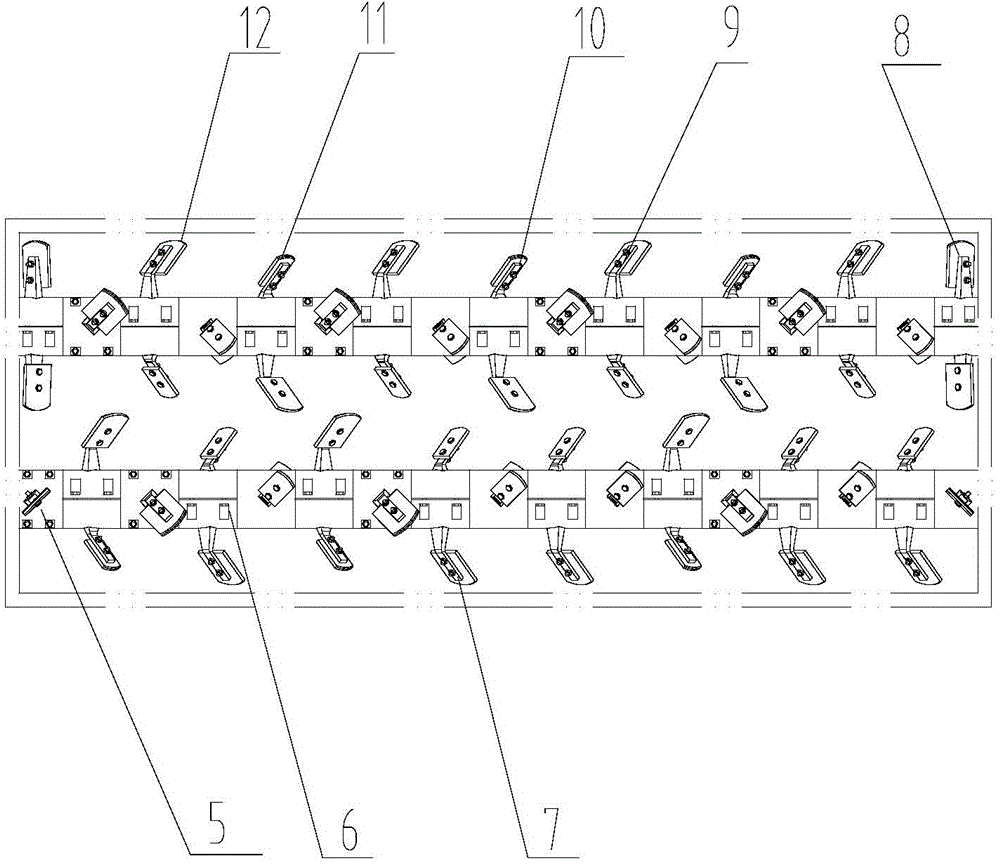

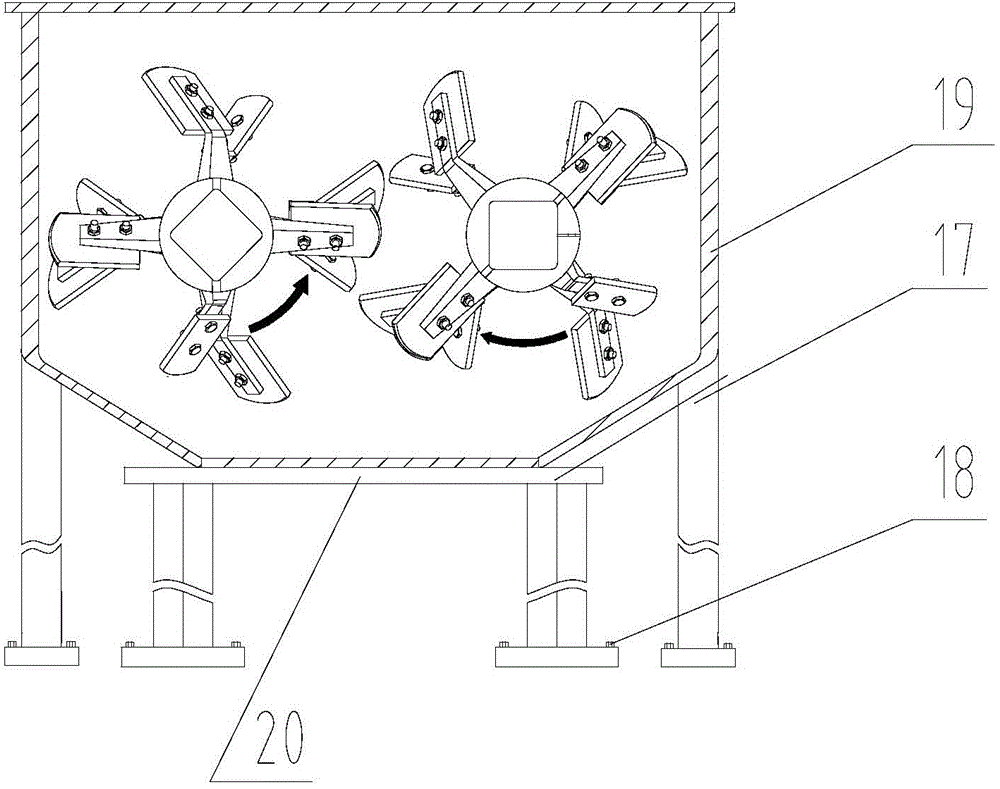

[0024] Such as Figures 1 to 3 As shown, the present invention has a twin-shaft continuous stirring device with opposed internal and external stirring units, including a frame 20 and a mixing drum 19 installed on the frame 20, a motor 1, a coupling 2 and a reduction box 4; Wherein, the left and right ends of the mixing drum 19 are respectively provided with a feed inlet and a discharge port; two parallel agitating shafts are respectively movably connected with the left and right side walls of the agitating drum 19, and the left ends of the two agitating shafts extend out to the stirring Outside the cylinder 19, the left end of the two stirring shafts is provided with an externally meshing synchronous gear 15, and each stirring shaft is provided with a number of external stirring units and internal stirring units at intervals from left to right; the output end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com