Industrial explosive robot neat production line

A technology of industrial explosives and robots, applied in conveyors, automatic packaging control, stacking of objects, etc., can solve the problems of poor equipment versatility, poor material handling ability in packaging processes, and high labor intensity, and achieve the effect of easy grasping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

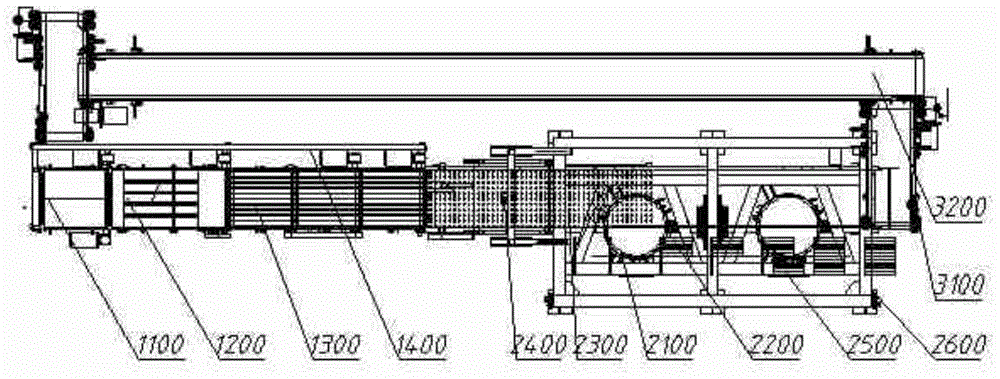

[0040] Such as figure 1 As shown, the industrial explosives robot shaping device is mainly composed of a drug roll shunting and shaping device 1000, a robot sorting and stacking device 2000, a return device 3000 and a control system;

[0041] The process flow of this device is as follows: Figure 11 Shown:

[0042] Arrangement of the device of the present invention

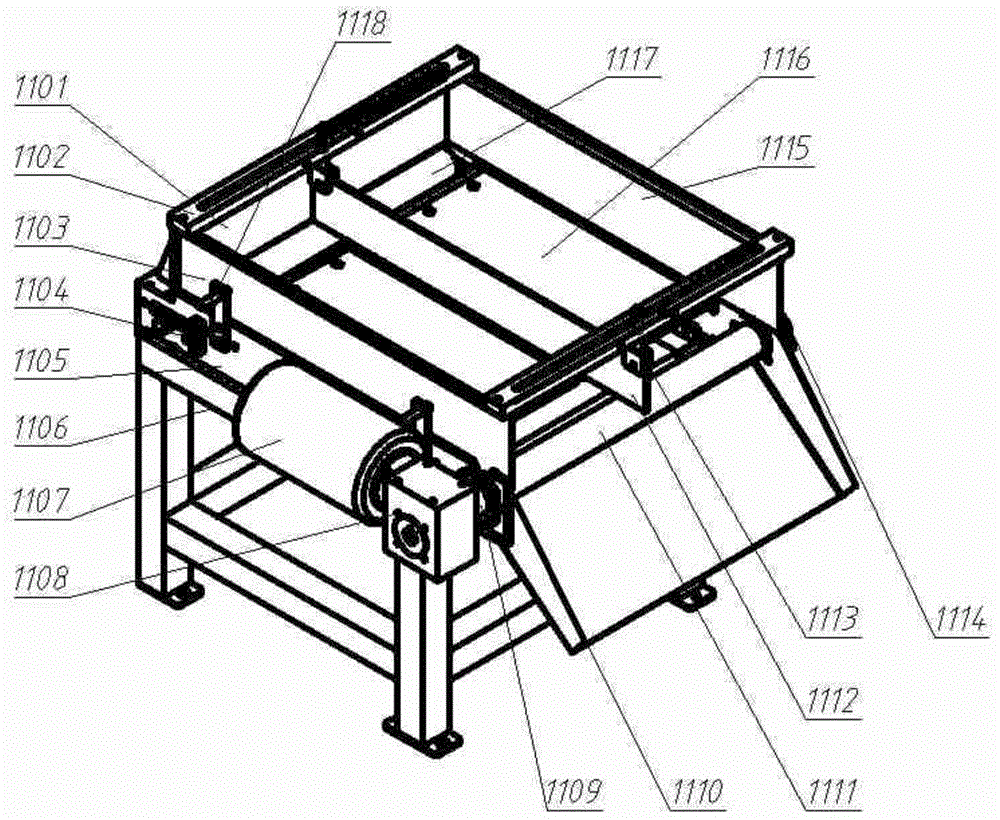

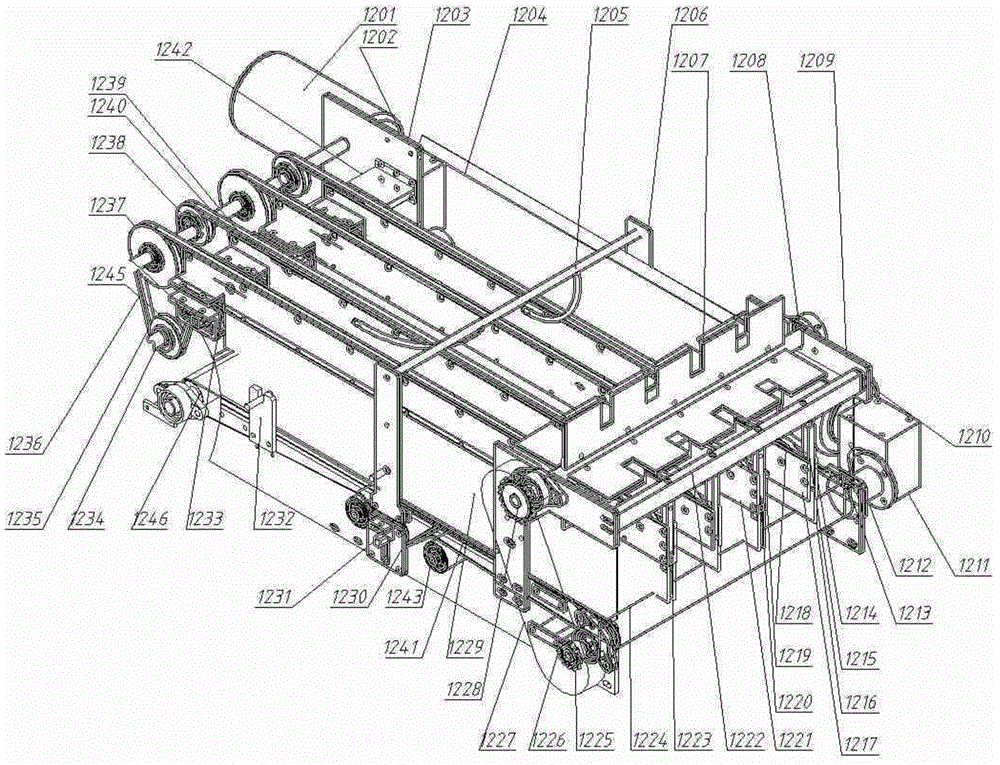

[0043] Such as figure 1 As shown, the industrial explosives robot shaping device is mainly composed of a drug volume shunting and shaping device 1000, a robot sorting and stacking device 2000, a return device 3000, and a control system; the control system is an electronic control part, which controls the coordinated actions of the entire production line and jointly completes Should have the function, the drug roll shunting and shaping device 1000 is composed of the transition belt machine 1100, the middle spacer belt shaping machine 1200, the multi-stage differential belt shaping machine 1300 and the frame part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com