SAPO-34/EU-1 composite molecular sieve and synthetic method thereof

A SAPO-34, composite molecular sieve technology, applied in the field of molecular sieve catalytic material synthesis, can solve the problems of difficult control of composite structure, insufficient physicochemical properties of composite molecular sieve, affecting adsorption and catalytic performance, etc., to achieve improved physicochemical properties and catalytic activity, good MTO Catalytic activity, effect of avoiding crystallinity drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

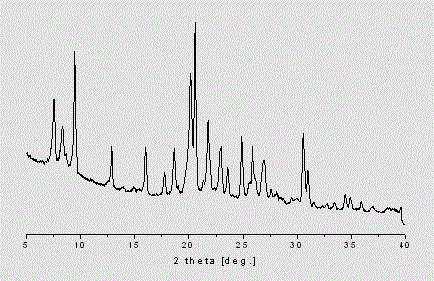

Image

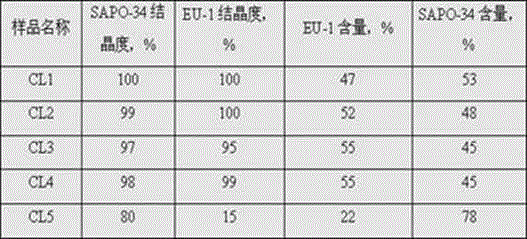

Examples

Embodiment 1

[0033] (1) Dissolve 40 g of glucose in 100 mL of distilled water, add 8 g of EU-1 molecular sieve into the glucose solution under stirring, stir for 30 min, place the mixture in an ultrasonic cleaner for 2 h, and then The mixture was filtered, and the obtained product was dried at 120° C. for 12 h, and then calcined at 500° C. for 2 h in a nitrogen atmosphere to obtain a pretreated EU-1 molecular sieve.

[0034] (2) Dissolve 11 g of aluminum isopropoxide in 45 mL of distilled water and stir for 30 min. Then add 4.6mL of phosphoric acid and stir for 30 min. Add 5 mL of ethyl orthosilicate and stir for 30 min. Then 4 mL of ethylenediamine was added and stirred for 30 min. Then add 8 g of EU-1 prepared in step (1) and stir for 30 min; then put it into a closed reactor and crystallize in an oven at 200 °C for 50 h. Then the obtained product was washed 4 times with distilled water to neutrality, then dried at 120°C for 12 hours, and finally calcined at 500°C for 2 hours in an ai...

Embodiment 2

[0036] (1) Dissolve 40 g of glucose in 100 mL of distilled water, add 8 g of EU-1 molecular sieve into the glucose solution under stirring, stir for 30 min, place the mixture in an ultrasonic cleaner for 2 h, and then The mixture was filtered, and the obtained product was dried at 120° C. for 12 h, and then calcined at 500° C. for 2 h in a nitrogen atmosphere to obtain a pretreated EU-1 molecular sieve.

[0037] (2) Dissolve 10 g of aluminum isopropoxide in 45 mL of distilled water and stir for 30 min. Then 5 mL of phosphoric acid was added and stirred for 30 min. Add 8 mL of ethyl orthosilicate and stir for 30 min. Then 10 mL of ethylenediamine was added and stirred for 30 min. Then add 8 g of EU-1 prepared in step (1) and stir for 30 min; then put it into a closed reactor and crystallize in an oven at 210 °C for 45 h. Then the obtained product was washed 4 times with distilled water to neutrality, then dried at 120°C for 12 hours, and finally calcined at 500°C for 2 hours...

Embodiment 3

[0039] (1) Dissolve 35 g of glucose in 100 mL of distilled water, add 7 g of EU-1 molecular sieve into the glucose solution under stirring conditions, stir for 30 min, place the mixture in an ultrasonic cleaner for 2 h, and then place the mixture After filtering, the obtained product was dried at 120° C. for 12 hours, and then calcined at 550° C. for 1.5 hours in a nitrogen atmosphere to obtain a pretreated EU-1 molecular sieve.

[0040] (2) Dissolve 8.5g of aluminum isopropoxide in 50 mL of distilled water and stir for 30 min. Then add 4.6mL of phosphoric acid and stir for 30 min. Then add 7g of white carbon black and stir for 30 min. Then 7 mL of ethylenediamine was added and stirred for 30 min. Then 6 g of EU-1 prepared in step (1) was added and stirred for 30 min; then it was placed in a closed reactor and crystallized in an oven at 180 °C for 60 h. Then the obtained product was washed 4 times with distilled water to neutrality, then dried at 120°C for 12 hours, and fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com