One-stage hydrogenation method for producing food-level white oil

A food-grade, white oil technology, applied in hydrogenation process, edible oil/fat, petroleum industry, etc., can solve the problems of complex process and high cost, and achieve simple process, many secondary holes, and low investment Effect

Active Publication Date: 2010-08-18

CHINA PETROLEUM & CHEM CORP +1

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

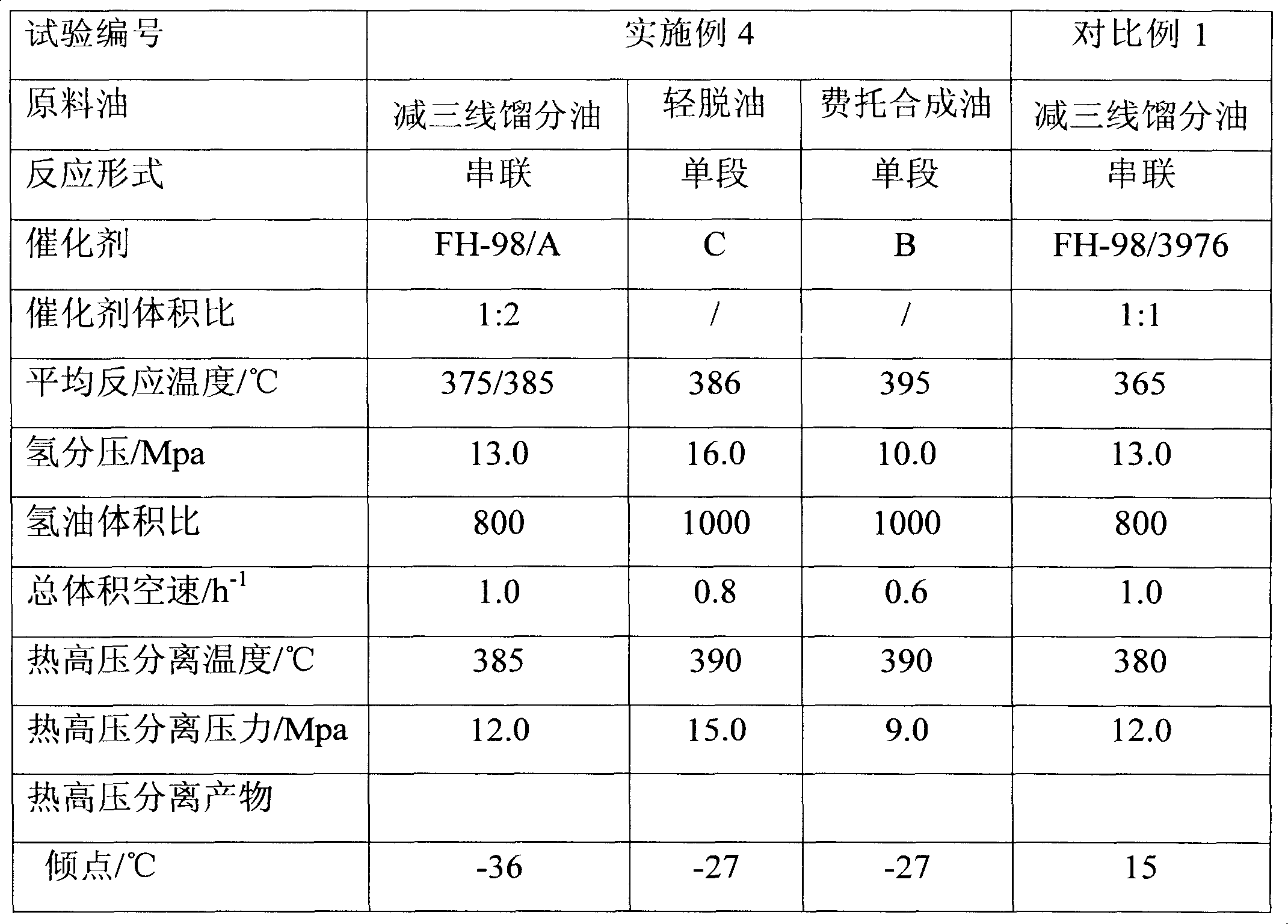

To sum up, the existing technology of producing food-grade white oil from vacuum distillate oil, solvent-refined deasphalted oil and Fischer-Tropsch synthetic oil requires at least three stages of hydrogenation to solve the problems of product pour point and aromatics content process, so the process is more complicated and the cost is higher

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

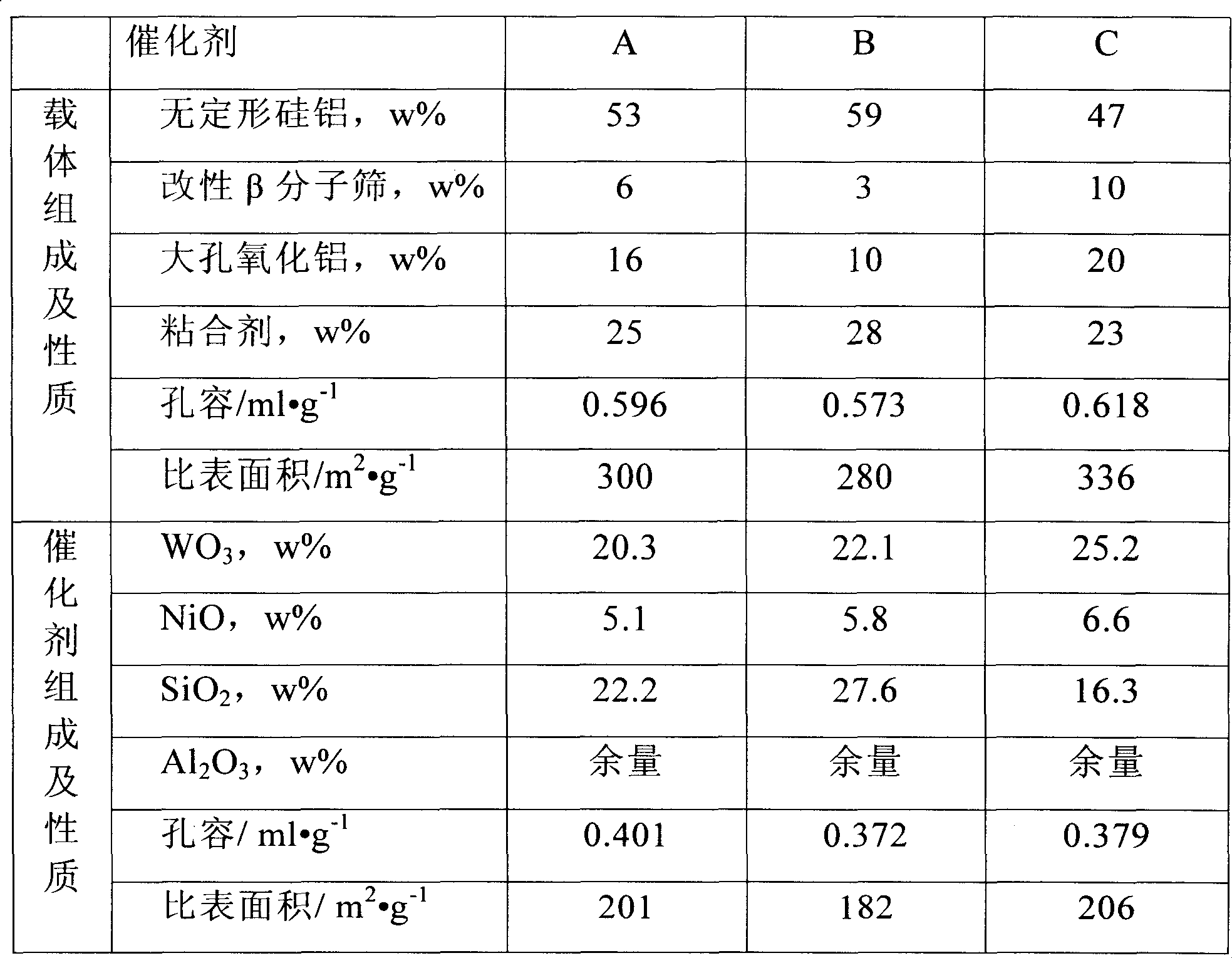

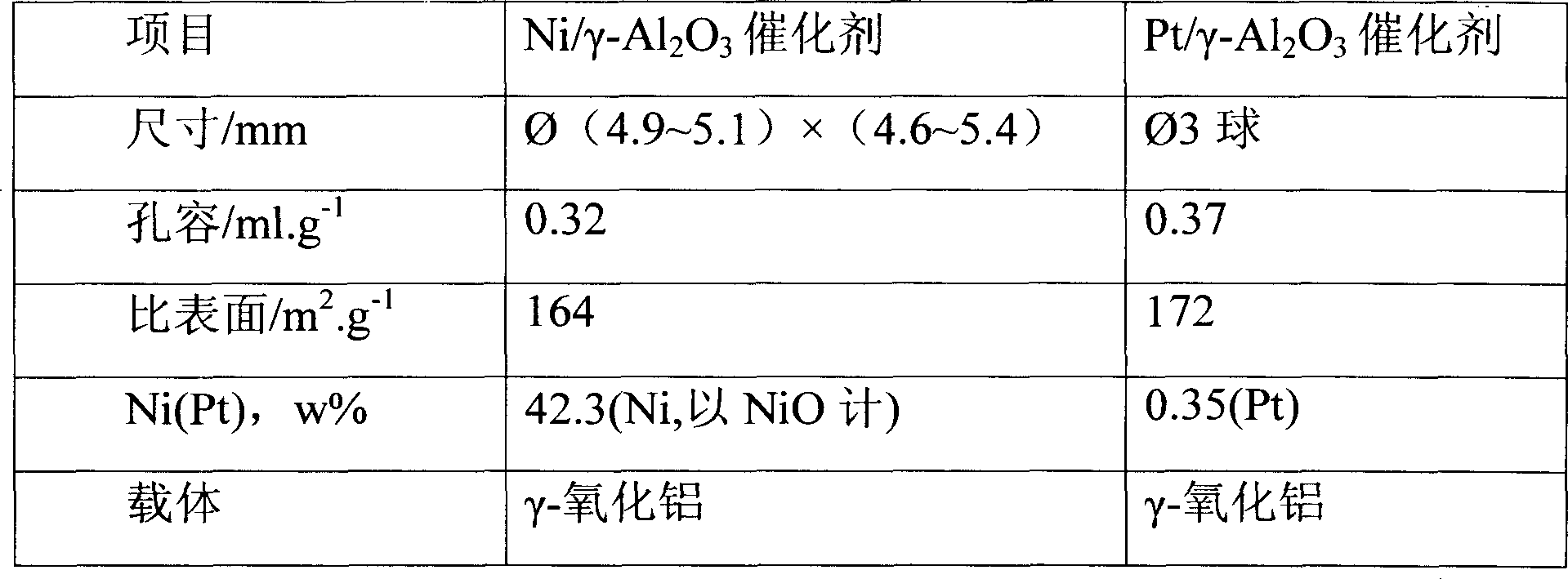

The present invention provides one-section hydrogenation process for producing food level white oil. By using vacuum gas oil, deasphalted solvent oil and Fischer-Tropsch process oil as material, and hydrogenating catalyst containing modified beta-molecular sieve in 1-9 wt%, and through hydrocracking or hydrogenating, hot high pressure separating out gas and light distillate to obtain liquid product, mixing with newly formed hydrogen, and high pressure hydro-finishing in a reactor with loaded reduction type hydrogenating catalyst, food level white oil is produced. The process is simple and hashigh product quality.

Description

technical field The invention relates to a method for producing food-grade white oil, specifically a method for producing food-grade white oil by a one-stage hydrogenation process. Background technique White oil is a type of petroleum product obtained by deep refining of lubricating oil fractions to remove impurities such as aromatics and sulfides in lubricating oil fractions. It is colorless, odorless and stable in chemical properties, and is widely used in chemical industry, daily necessities, food, medicine, textile and agriculture and other fields. According to different uses and refining depths, white oil can be divided into industrial, cosmetic, food and pharmaceutical categories. Among them, food-grade white oil is the most refined. The white oil production process is mainly the process of removing sulfur, nitrogen, aromatics and other impurities from the base oil. The production process of white oil mainly includes: old three methods, sulfonation method and hydro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10G45/02C10G65/04A23D9/02

Inventor 关明华全辉姚春雷刘平林振发

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com