Self-healing organic matter/inorganic nanoparticle hybrid material and preparation method thereof

A technology of inorganic nanoparticles and hybrid materials, which is applied in the field of organic-inorganic hybrid materials and its preparation, can solve problems such as poor mechanical strength, and achieve the effect of strong self-healing recovery ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

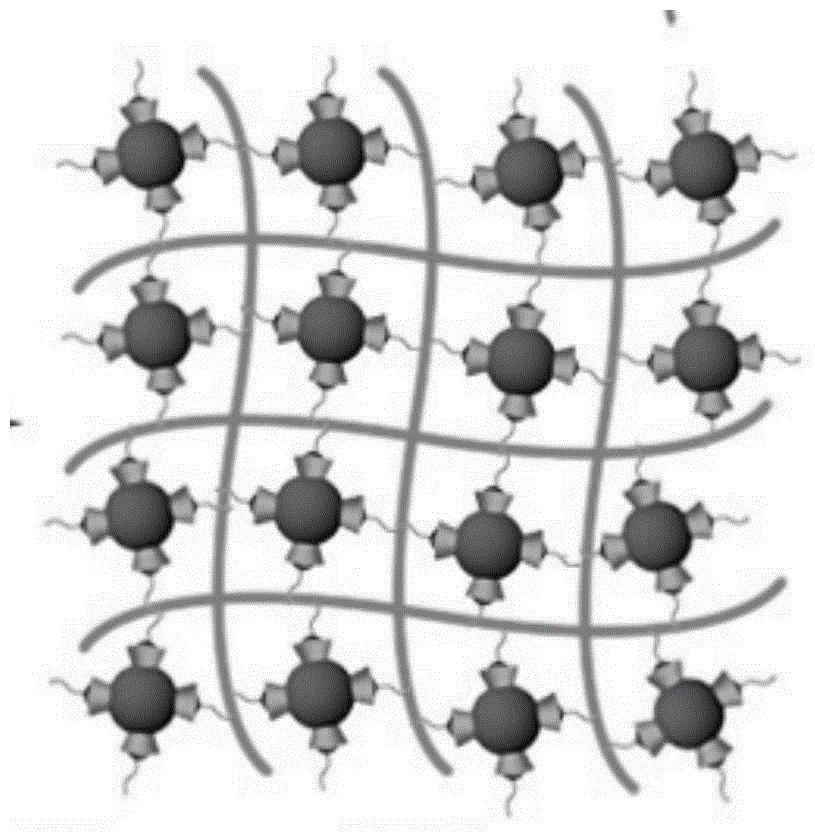

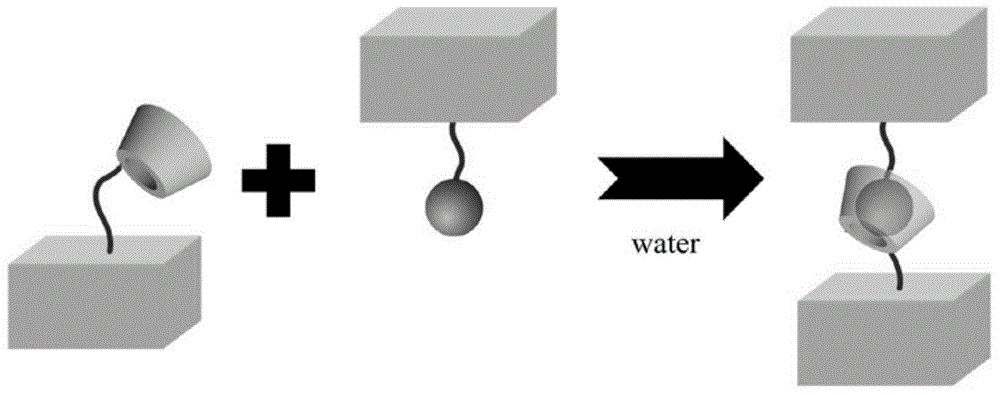

[0024] Dissolve adamantyl acrylate in DMSO solution (concentration: 8%), and β-cyclodextrin-modified ferroferromagnetic particles are dispersed in water (concentration: 2%). Then the two were mixed (the molar ratio of adamantane to β-cyclodextrin was 1:1) and stirred for 5 hours, and the adamantyl acrylate not involved in the assembly was removed by centrifugation. The assembled adamantyl acrylate / β-cyclodextrin-ferric iron tetroxide and butyl acrylate in a weight ratio of 1:5, using tetrahydrofuran as a solvent, AIBN as an initiator, ethylene glycol dimethacrylate (EGDMA ) is a cross-linking agent for copolymerization and cross-linking, and the reaction time is 12 hours. After the reaction is completed, the solvent is removed by vacuum drying for 40 hours, and the polyacrylic acid-adamantane / β-cyclodextrin-ferric oxide material can be obtained.

[0025]The polyacrylate / β-cyclodextrin-ferric oxide was cut in half, and then the cross-section was gently closed. After 0.5 hours,...

Embodiment 2

[0027] Vinyl azobenzoate was dissolved in DMSO solution (concentration: 3%), and α-cyclodextrin-modified graphene was dispersed in water (concentration: 5%). Then the two were mixed (the molar ratio of azobenzene to α-cyclodextrin was 1:1) and stirred for 3 hours, then centrifuged to remove vinyl azobenzoate that did not participate in the assembly. The assembled vinyl azobenzoate / α-cyclodextrin-graphene and hydroxyethyl acrylate are in a weight ratio of 1:3, using tetrahydrofuran as a solvent, AIBN as an initiator, and ethylene glycol dimethacrylate ( EGDMA) is cross-linking agent, carries out copolymerization and cross-linking, and the reaction time is 15 hours. After the reaction is completed, the solvent is removed by vacuum drying for 40 hours to obtain a polyacrylate-polyvinyl azobenzoate / α-cyclodextrin-graphene material.

[0028] The polyacrylate-polyvinyl azobenzoate / α-cyclodextrin-graphene was cut in half, and then the cross-section was gently closed. After 1 hour, t...

Embodiment 3

[0030] Ferrocene-modified sodium alginate (substitution degree: 8%) was dissolved in aqueous solution (concentration: 5%), and β-cyclodextrin-modified graphene was dispersed in water (concentration: 5%). Then the two were mixed (the molar ratio of ferrocene to β-cyclodextrin was 0.4:1) and stirred for 10 hours, then dialyzed for 48 hours to remove sodium alginate not involved in assembly. Concentrate the above-mentioned liquid after dialysis to remove most of the water, and then add 10% calcium chloride as a physical cross-linking agent to obtain sodium alginate-ferrocene / β-cyclodextrin-graphene gel.

[0031] The sodium alginate-ferrocene / graphene-β-cyclodextrin was cut in half, and then the cross-section was gently closed. After 5 hours, the material healed. The tensile strength after healing was 69% of the original strength. Self-healing can be repeated many times (cut and heal more than 3 times at the same site, and the tensile strength after healing is more than 50% of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com