Polylactic acid/polyester alloy and preparation method thereof

A technology of polyester alloy and polylactic acid, which is applied in the field of polymers, can solve the problems of unstable phase structure, difficult to meet, toughness, rigidity, heat resistance and other problems, so as to avoid design difficulty and reduce investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

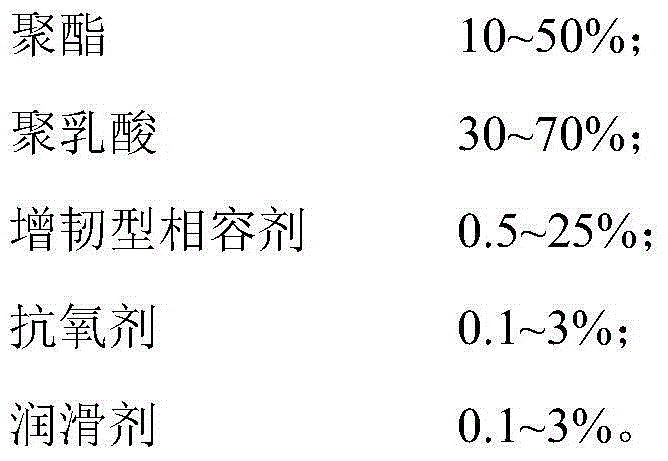

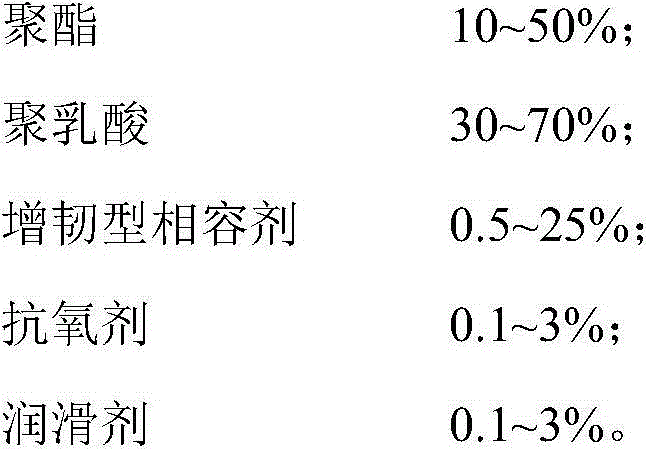

Method used

Image

Examples

Embodiment 1

[0029] 1000g each of PLA and PC, dried at 80°C for 2h, compatibilizer (styrene-butadiene-acrylonitrile-GMA) 300g, antioxidant (168 / 1010) 60g, lubricant (TAF) 40g, using the above extrusion After mixing the above raw materials for 3 to 5 minutes in a high-speed mixer, they were respectively put into a two-stage extruder with an ultrasonic treatment power of 400W, extruded and granulated to obtain sample 4, and the granules were dried at 90°C for 3 hours, and then injection molded into samples. strip, test.

Embodiment 2

[0031] PLA 800g and PC 1200g, dried at 80°C for 2h, compatibilizer (styrene-butadiene-acrylonitrile-GMA) 300g, antioxidant (168 / 1010) 60g, lubricant (TAF) 40g, using the above Extrusion process, the above raw materials are mixed by a high-speed mixer for 3 to 5 minutes, and then put into a two-stage extruder respectively, with an ultrasonic treatment power of 500W, extruded and granulated to obtain sample 5, and the particles are dried at 90°C for 3 hours, and then injection molded into Spline, test.

Embodiment 3

[0033] PLA 1400g and PC 600g, dried at 80°C for 2h, compatibilizer (styrene-butadiene-acrylonitrile-GMA) 600g, antioxidant (168 / 1010) 60g, lubricant (TAF) 40g, using the above Extrusion process, the above raw materials are mixed by a high-speed mixer for 3 to 5 minutes, and then put into a two-stage extruder respectively, with an ultrasonic treatment power of 350W, extruded and granulated to obtain sample 6, and the granules are dried at 90°C for 3 hours, and then injection molded into Spline, test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com