Method for cultivating schizochytrium oil-producing grease employing schizochytrium and crude glycerine

A technology of Schizochytrium and crude glycerin, applied in the field of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment one: the pretreatment of biodiesel by-product crude glycerin

[0041] Crude glycerin, a by-product of biodiesel, is obtained from biodiesel production enterprises, and is used to produce biodiesel from kitchen waste oil.

[0042] After mixing crude glycerol, a by-product of biodiesel, with water at a ratio of 1:4 (V:V), adjust the pH to 6.5, fatty acids form fatty acid salt (soap) precipitation, centrifuge at 4000 rpm for 10 minutes to remove soap to obtain crude glycerin, and then Sterilize with high pressure steam for 10 minutes (to be sterilized after the medium is prepared when it is used to prepare the medium in the future) to remove methanol.

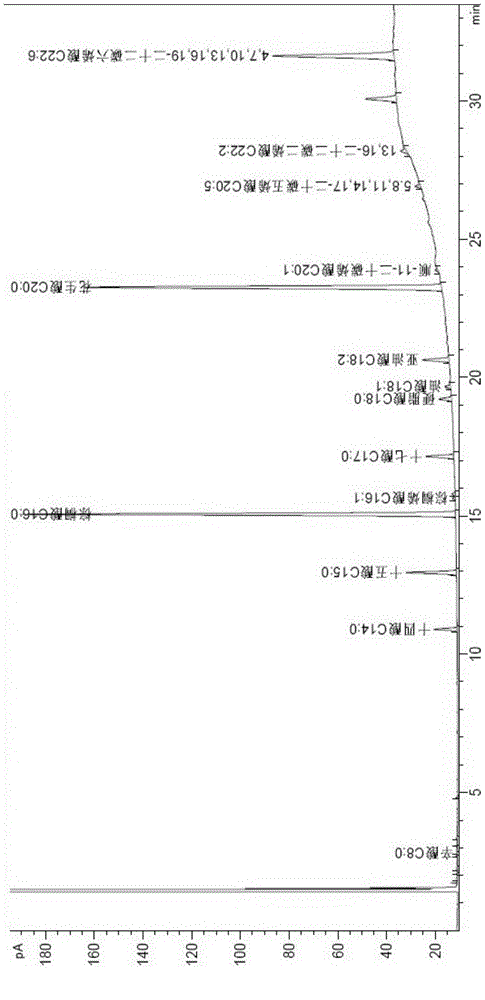

[0043] The pretreated crude glycerin was analyzed for relevant components, and the results are shown in Table 1. Minerals were measured by atomic absorption spectrophotometry, glycerol content was measured by potassium periodate method (Li Sumin, Chinese Journal of Blood Transfusion, 1999, 12(3):179~179), fatty ...

Embodiment 2

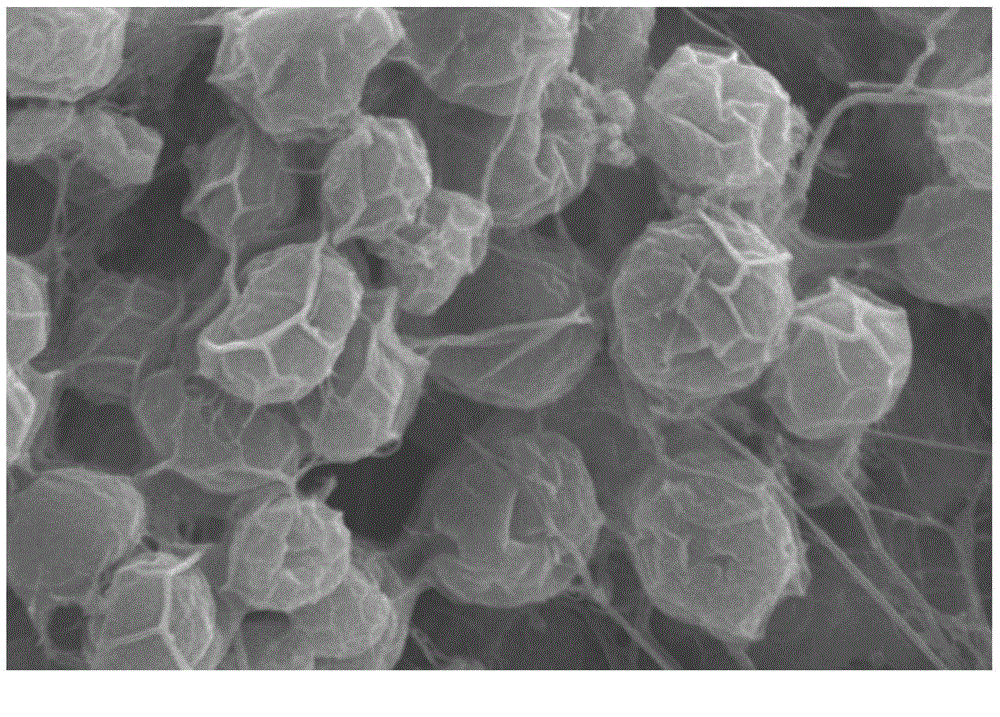

[0046] Embodiment two: Mutation breeding of oil-producing Schizochytrium

[0047] The starting strain is Schizochytrium sp. WZU6961 (the source of genetic resources is disclosed in the patent "Method for High-density Fermentation of Schizochytrium sp. to Produce DHA (Application No.: 201210338013.0)"). Obtained isolated from decaying leaves of woods.

[0048] Get the preserved bacterial strain (2.0ml thawed bacterial liquid) and inoculate in 50ml liquid culture medium (medium formula (g·L -1 ): crude glycerin 30 (actual glycerol after conversion), yeast powder 10, NaCl 15, KCl 0.5, MgSO 4 ·7H 2 O2.0, K 2 SO 4 0.65, KH 2 PO 4 1.0, (NH 4 ) 2 SO 4 1.0, CaCl 2 2H 2 O 0.17, MnCl 2 4H 2 O0.003, ZnSO 4 ·7H 2 O 0.003, CoCl 2 ·6H 2 O 0.00004, Na 2 MoO 4 2H 2 O 0.00004, CuSO 4 ·5H 2 O 0.002, NiSO 4 ·6H 2 O 0.002, FeSO 4 ·7H 2(0.01, pH natural), cultivated at 30°C, 150-160rpm for 72h to activate the strain, then transferred to a new liquid medium at 5% volume ra...

Embodiment 3

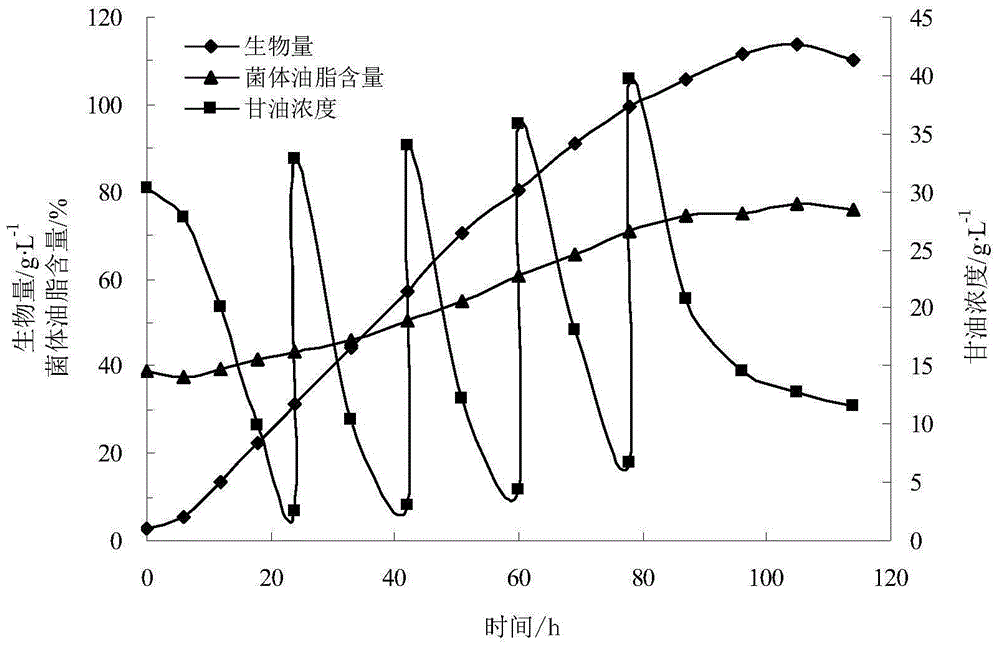

[0051] Example 3: Optimization of culture conditions for oil production by culturing Schizochytrium with crude glycerin

[0052] Inoculate the preserved bacterial strain (2.0ml thawed bacterium liquid) in the 250ml Erlenmeyer flask that 50ml seed culture medium (formula is the same as Example 2) is housed, cultivate 72h to activate under 30 ℃, 150~160rpm; Then press 5% The volume ratio is transferred in the 500ml Erlenmeyer flask that 100ml seed culture medium is housed, cultivates 48h to obtain seed at 30 ℃, 160rpm; Then transfer to the 100ml fermentation medium that is housed by 5% volume ratio (basic formula is the same as seed cultivation Base) in the 500ml Erlenmeyer flask, at a certain temperature, 150 ~ 160rpm under cultivation 72h, measure biomass, thalline fat content, assay method is the same as embodiment two.

[0053] The effects of nitrogen source types, growth factors, pH, and temperature on the growth and oil accumulation of Schizochytrium were mainly discussed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com