Sluice back type hydropower station

A technology for power stations and hydropower, which is applied in the fields of hydropower, reaction engines, and engine components. problem, to achieve the effect of prominent comprehensive utilization benefit function, easy implementation and low cost of new construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

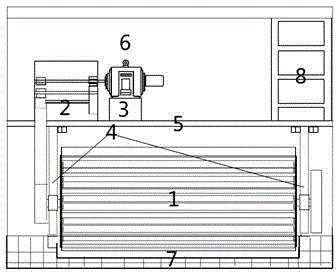

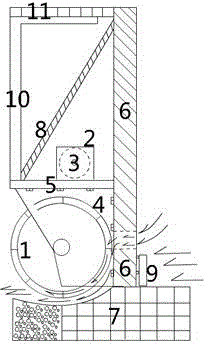

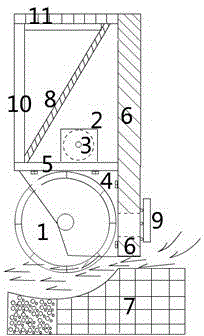

[0026] like figure 1 As shown: the sluice-back hydropower station described in this embodiment is mainly composed of a water turbine 1, a synchronous belt drive speed increaser 2, a generator 3, a sluice 6, a water turbine room 7, a speed-regulating sluice 9 and a station building. 6 can be any water gate of known equipment. A water inlet is provided at the bottom of the water gate 6, and a speed-regulating water gate 9 is arranged at the water inlet. "Patent, it is connected in front of the water gate 6 (facing the water), and is slidably connected with the water gate 6. On the back of the sluice 6 (the backside of the water) are connected a water turbine 1, a synchronous belt drive speed increaser 2, a generator 3 and a station building. The water turbine 1 is horizontally arranged in the station building, and the water pecking method is horizontal water pecking. Wha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com