Form auto-lifting system and method for slip-form construction of thin-walled hollow high piers

An automatic lifting and hollowing technology, which is applied in the field preparation of formwork/formwork/working frame, building components, construction, etc., can solve the problems of large concrete surface modification range, inaccurate lifting time of sliding form, concrete surface collapse or cracking and other problems to achieve the effect of improving the appearance quality defects of concrete, avoiding the surface modification process, and improving the construction progress of the slip form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

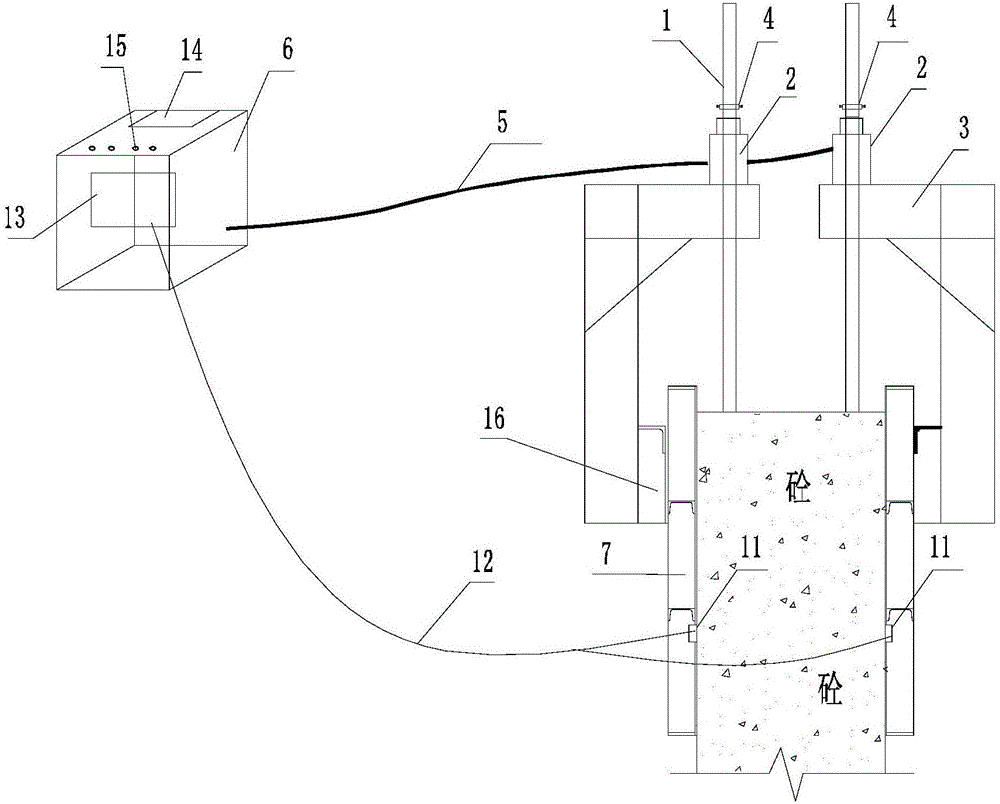

[0017] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the described specific embodiments are only for explaining the present invention, and are not intended to limit the present invention.

[0018] The design concept of the present invention is: by installing the miniature pressure sensor 11 on the surface that the steel formwork 7 contacts with the concrete veneer, test the strength of the mold release before the initial setting of the concrete, and transmit the strength value to the PLC of the hydraulic console 6 through the transmission line Programmable controller 13, thus completes the promotion of automatic steel formwork 7 according to the needed die-out strength.

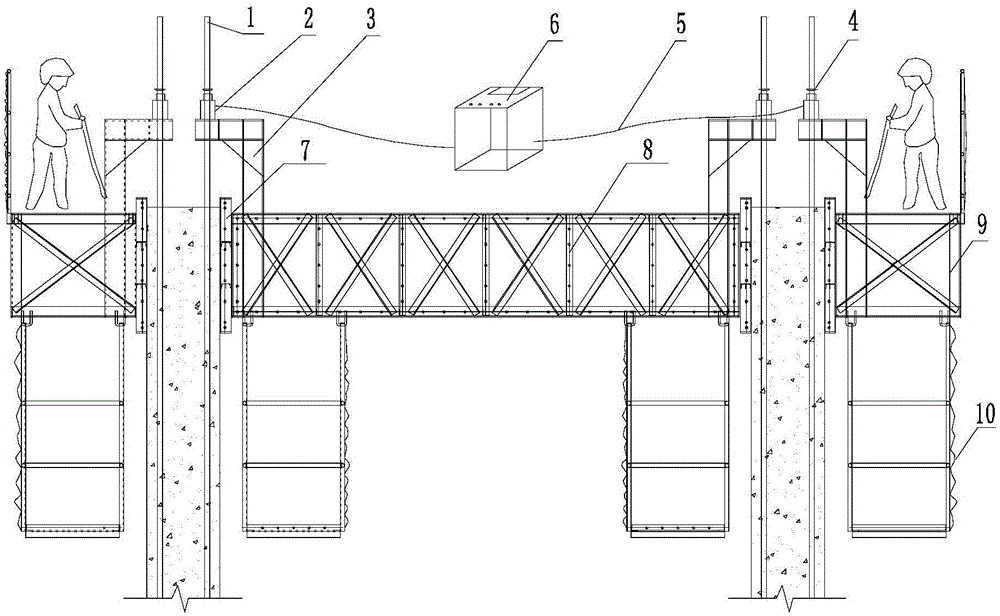

[0019] Such as figure 2 as shown ( figure 2 Platform trusses and symmetrical parts are omitted), a formwork automatic lifting system for thin-walled hollow high pier slipform construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com