Hot blast stove

A technology of hot blast stove and hot blast channel, which is applied in the direction of air heater, fluid heater, lighting and heating equipment, etc. It can solve the problems of affecting the use environment, polluting the environment, and producing a large amount of dense smoke, so as to improve thermal efficiency, reduce pollution, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

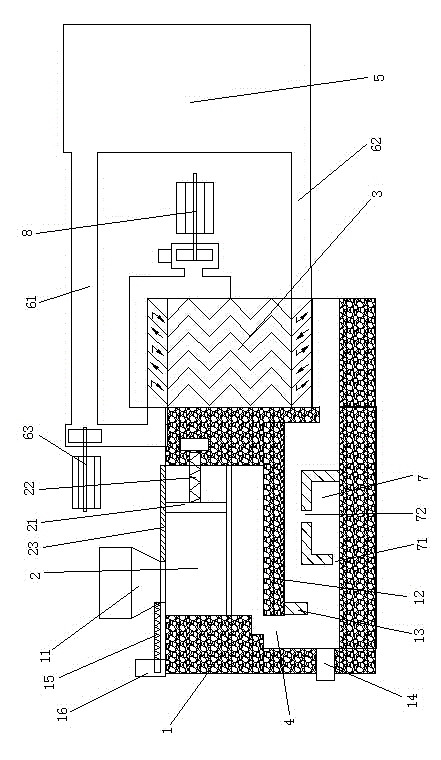

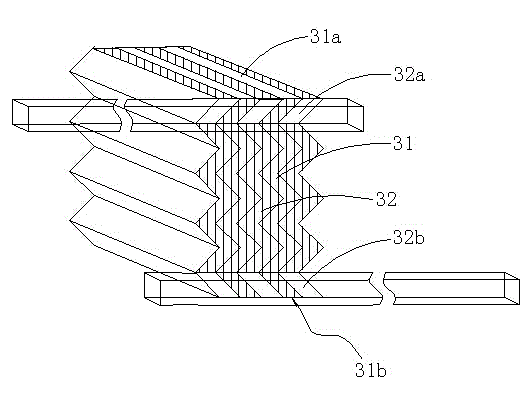

[0026] Such as Figure 1 to Figure 2 As shown, a hot blast stove includes a housing 1, the housing 1 is provided with a refueling port 11, the housing 1 is provided with a combustion chamber 2 and a heat exchanger 3, the combustion chamber 2 is provided with an air inlet, and the heat The exchanger 3 is composed of flue gas passages 31 and hot air passages 32 arranged alternately and in a continuous bending structure. The flue gas passages 31 are closed on both sides and open up and down. Road 4 is connected, and the upper opening 31a of the flue gas passage 31 cooperates with the first induced draft fan 8; the two sides of the hot air passage 32 are closed, and the upper and lower ends are also closed, and the upper and lower ends of the hot air passage 32 sides are respectively provided with upper openings 32a and The lower opening 32b, the opening of the hot air channel 32 communicates with the air channel, and the air channel is provided with a second induced draft fan 63;...

Embodiment 2

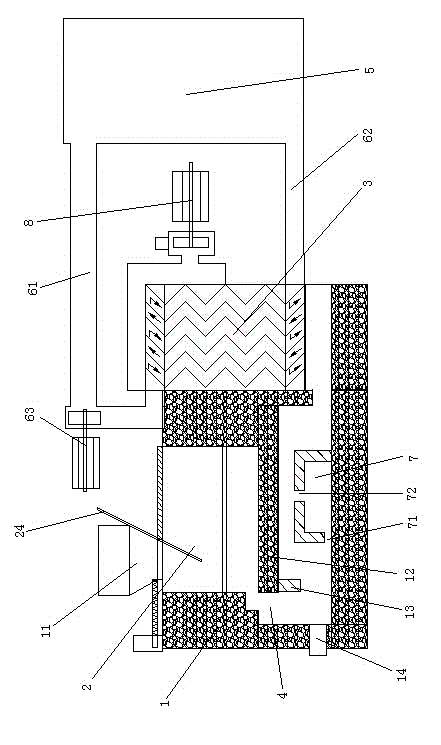

[0046] Such as image 3 As shown, the structure of the hot blast stove in this embodiment is similar to that of the hot blast stove in Embodiment 1, the difference is that: the bottom of the fuel inlet 11 of the hot blast stove is obliquely provided with a charging regulating plate 24, and the charging regulating plate The bottom of 24 stretches in the combustion chamber 2. The purpose of adjusting the amount of fuel added is achieved by twitching the feeding regulating plate 24 obliquely, and the structure is simpler and more practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com