Method and device for detecting tobacco stem outline structures based on images

A technology for structure detection and tobacco stems, which is applied to measurement devices, image enhancement, image data processing, etc., can solve the problems of inability to obtain the shape, structure, size and length distribution of tobacco stems, large detection errors, and high labor intensity, and achieves a high level of improvement. Quality control level, low equipment investment cost, and the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

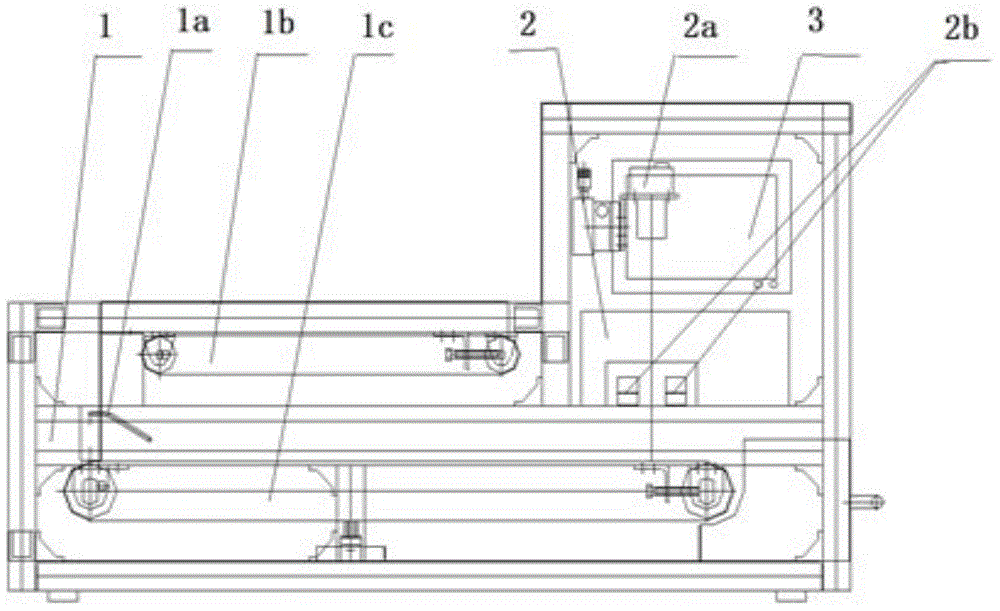

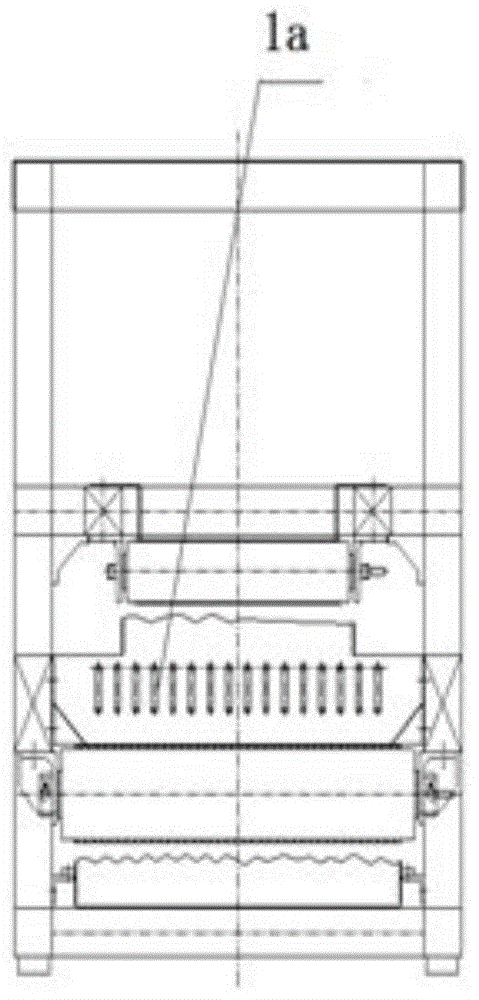

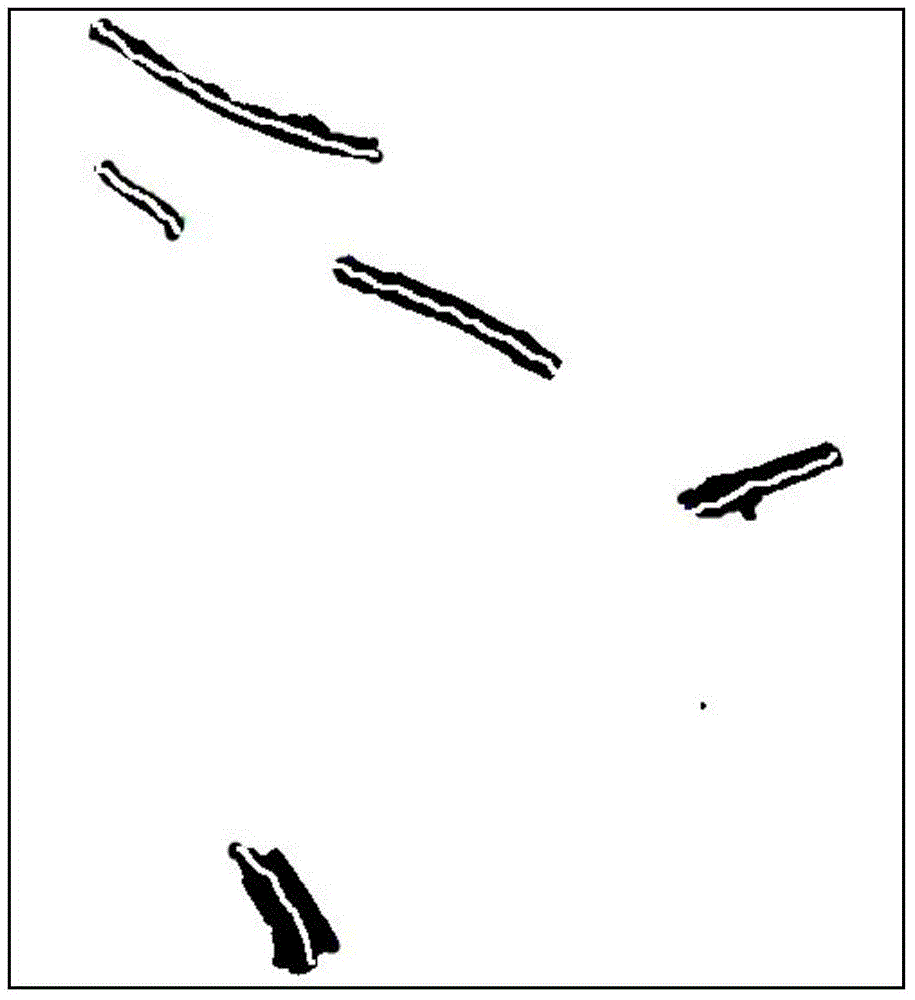

[0032] Such as figure 1 As shown, the detection device for detecting the shape and structure of tobacco stems using the image method includes a tobacco stem discrete device 1 and an image collector 2 located above the high-speed belt conveyor 1c of the tobacco stem discrete device 1, and an image processing device connected to the image collector 2 computer system3. The image collector 2 includes an industrial line scan camera 2a and two LED bar light sources 2b. The scanning line of the industrial line scan camera is just located in the middle of the two LED light sources to ensure the best imaging effect. The tobacco stem discrete device 1 includes a low-speed cloth and a flow control belt conveyor 1b, and a lever 1a located below the discharge port of the low-speed belt conveyor. The angle between the lever and the falling direction of the tobacco stems is about 120 degrees, which can effectively prevent the tobacco stems from falling. Stuck on the pusher rod, the pusher r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com