Manual stress control type triaxial compressor

A technology of compression instrument and triaxial instrument, which is applied in the direction of testing material strength by applying stable tension/compression, testing material strength by applying stable shear force, etc., which can solve the problem of greatly increased cost of manufacturing instruments, high cost, and low instrument prices. Expensive and other issues, to achieve the effect of easy maintenance, low cost, intuitive principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

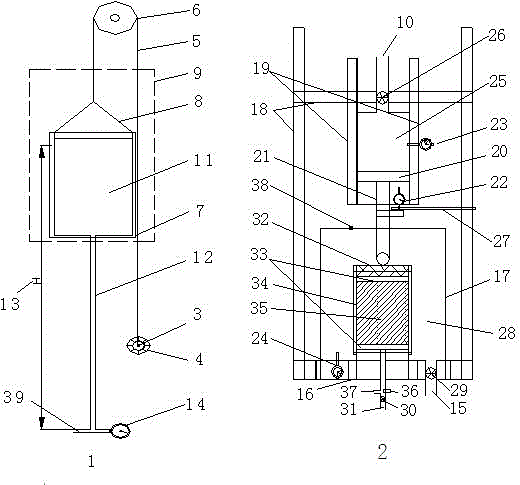

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0011] see figure 1 , carry out the test according to the following steps.

[0012] 1 Sample preparation and saturation

[0013] The preparation and saturation of the sample were carried out with reference to Section 4.1 and Section 4.2 of the Triaxial Compression Test (SL237-017-1999) in the industry standard geotechnical test regulations of the Ministry of Water Resources of the People's Republic of China.

[0014] 2. Sample installation and consolidation

[0015] (1) For the unconsolidated and undrained test (UU test)

[0016] 1) The installation of the sample and the water injection of the surrounding pressure chamber refer to the provisions of Articles 1 to 4 of Section 4.3.1 of the Triaxial Compression Test (SL237-017-1999) in the Industry Standard Geotechnical Test Regulations of the Ministry of Water Resources of the People's Rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com