Composite maximum-dip-angle fiber bragg grating biochemical sensor and production method thereof

A technology of biochemical sensors and tilted fiber gratings, which is applied to instruments, scientific instruments, and material analysis through optical means, and achieves the effects of simple structure, high safety, and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

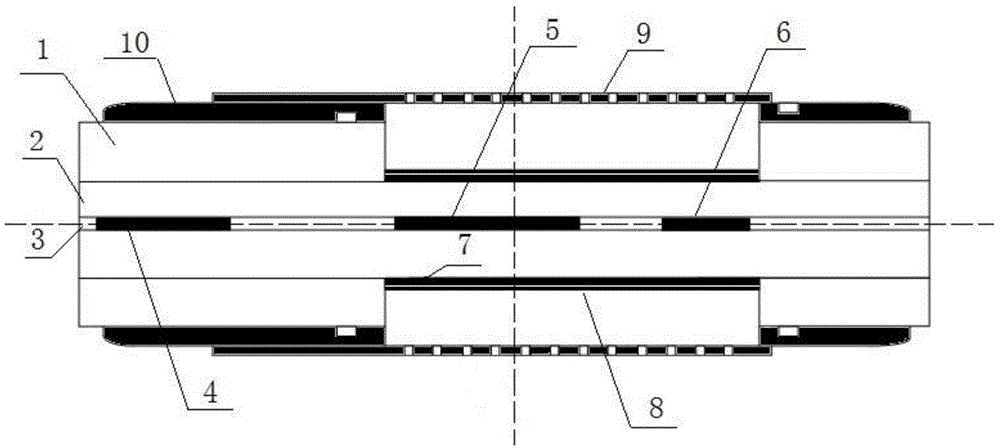

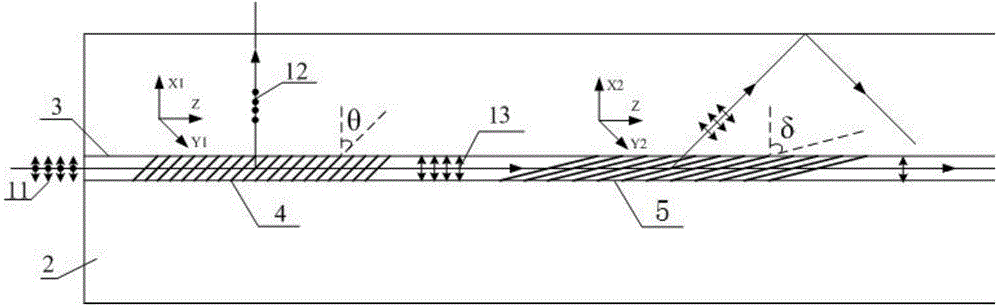

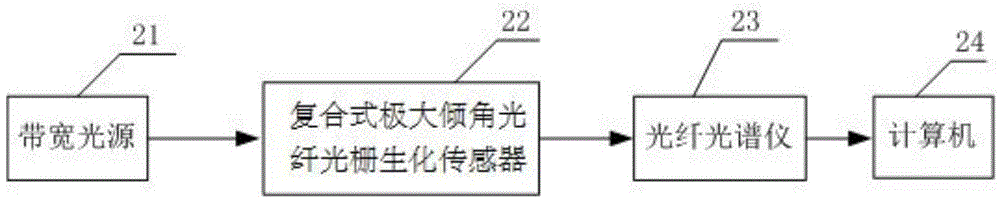

[0034] see Figure 1 to Figure 6 , a composite extremely tilted fiber grating biochemical sensor, comprising an optical fiber core 3 and an optical fiber cladding 2 wrapping the optical fiber core 3, characterized in that: the front section of the optical fiber core 3 is provided with a first inclined optical fiber grating 4, the second The angle θ between the slanted grating stripes of a slanted fiber grating 4 and the longitudinal axis of the optical fiber is 45°; the first slanted fiber grating 4 is used as a polarizer of a compound biochemical sensor; the first half of the middle section of the optical fiber core 3 is provided with a second Two tilted fiber gratings 5, the second tilted fiber grating 5 is used as an optical resonant coupler between the fiber core 3 and the fiber cladding 2; the angle δ between the tilted grating stripes of the second tilted fiber grating 5 and the longitudinal axis of the fiber is 79 °~84°; the fast axis and slow axis of the first tilted f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com