Gas sensor and method for detecting methane gas concentration in septic tank using same

A gas sensor and gas technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of poor sealing performance, low detection accuracy, slow response speed, etc., and achieve improved detection accuracy, sensitivity, and response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

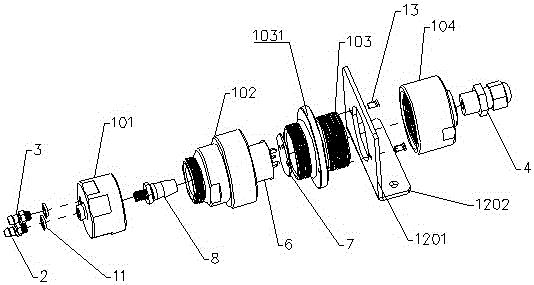

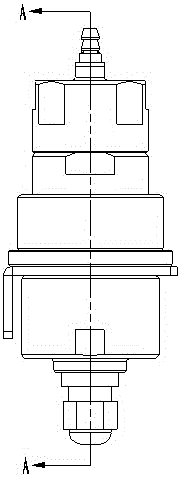

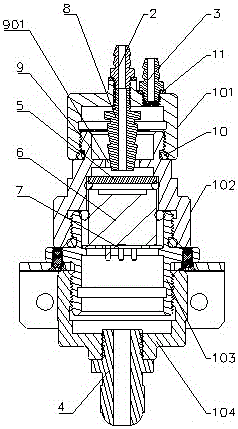

[0037] A gas sensor, comprising a housing with a cavity inside, the housing includes an upper housing 101, a fixing base 102, a base 103 and a lower housing 104, the upper housing, the fixing base, the base and the lower housing They are all made of 304 stainless steel with strong anti-corrosion properties. The top of the upper casing is provided with an air intake nozzle 2 and an exhaust nozzle 3 side by side, and the air intake nozzle is located at the center of the top of the upper casing, and the exhaust nozzle is set close to the air intake nozzle. , which improves the distribution uniformity of the gas in the accommodation space formed between the step and the detection element, which is beneficial to the improvement of the detection accuracy of the gas sensor, and also includes the anti-loosening gasket 11. After the gasket 11 is loosened, it is threadedly connected with the upper casing 101, and the air intake nozzle and the exhaust nozzle are made of corrosion-resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com