Determination method for levels of three factors in rubber powder modified cement stabilized crushed stone mixture

A cement-stabilized gravel and determination method technology, which is applied in the determination of the level of three factors, rubber powder modified cement stabilized gravel mixture, to achieve accurate results, improve comprehensive performance, and reasonable number of tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

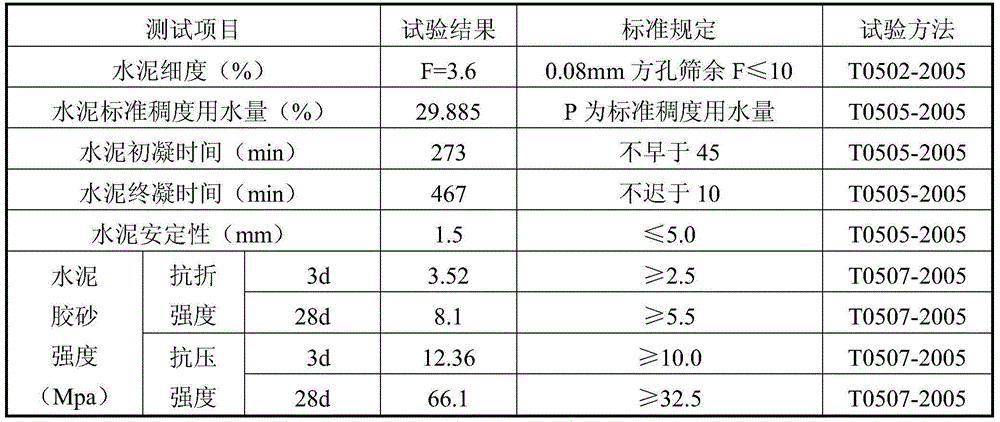

Embodiment 1

[0039] A method for determining the level of three factors in a rubber powder modified cement stabilized gravel mixture, which comprises the following steps in sequence:

[0040] Step 1: Determine the level of the three factors in the rubber powder modified cement stabilized gravel mixture, and use the orthogonal test design method to carry out test design;

[0041] Step 2: According to the results of the orthogonal test design, design the compaction test of the rubber powder modified cement stabilized gravel mixture;

[0042] Step 3: According to the compaction test results of the rubber powder modified cement stabilized macadam mixture, analyze the influence of three factors on the maximum dry density of the rubber powder modified cement stabilized macadam mixture;

[0043] Step 4: According to the compaction test results of the rubber powder modified cement stabilized gravel mixture, the rubber powder modified cement stabilized gravel mixture is prepared, and the unconfined...

Embodiment 2

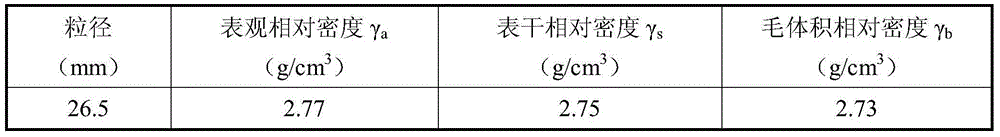

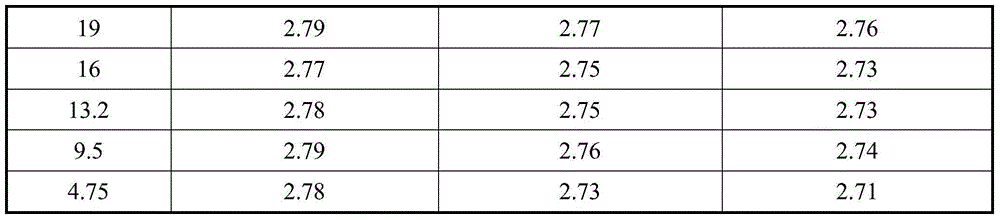

[0080] A method for determining the level of three factors in a rubber powder modified cement-stabilized gravel mixture, its steps, the strength grade and performance index of the cement used, the source and performance index of the aggregate used, and the synthesis level of the cement-stabilized gravel mixture The source and physical properties of compounding, rubber powder used etc. are all identical with embodiment one.

[0081] This example still adopts the three-factor three-level orthogonal test design method, and its orthogonal test design table is shown in Table 2.1.

[0082] Table 2.1 Three-factor three-level orthogonal test design table

[0083]

[0084] According to the results of three-factor and three-level orthogonal test design in this example, the compaction test of rubber powder modified cement stabilized gravel mixture is designed, and the compaction test results are shown in Table 2.2.

[0085] Table 2.2 Compaction test results of rubber powder modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com