Process cartridge for image forming apparatus

A technology for processing cartridges and images, which is applied in the directions of instruments, optics, clamping/spring connections, etc., can solve the problem that the developing element cannot be close to the photosensitive element, etc., achieve the effect of improving the contact effect, ensuring the printing quality, and facilitating the production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make those skilled in the art more easily and clearly understand the technical solutions involved in the present invention, the following description will be made in conjunction with specific embodiments.

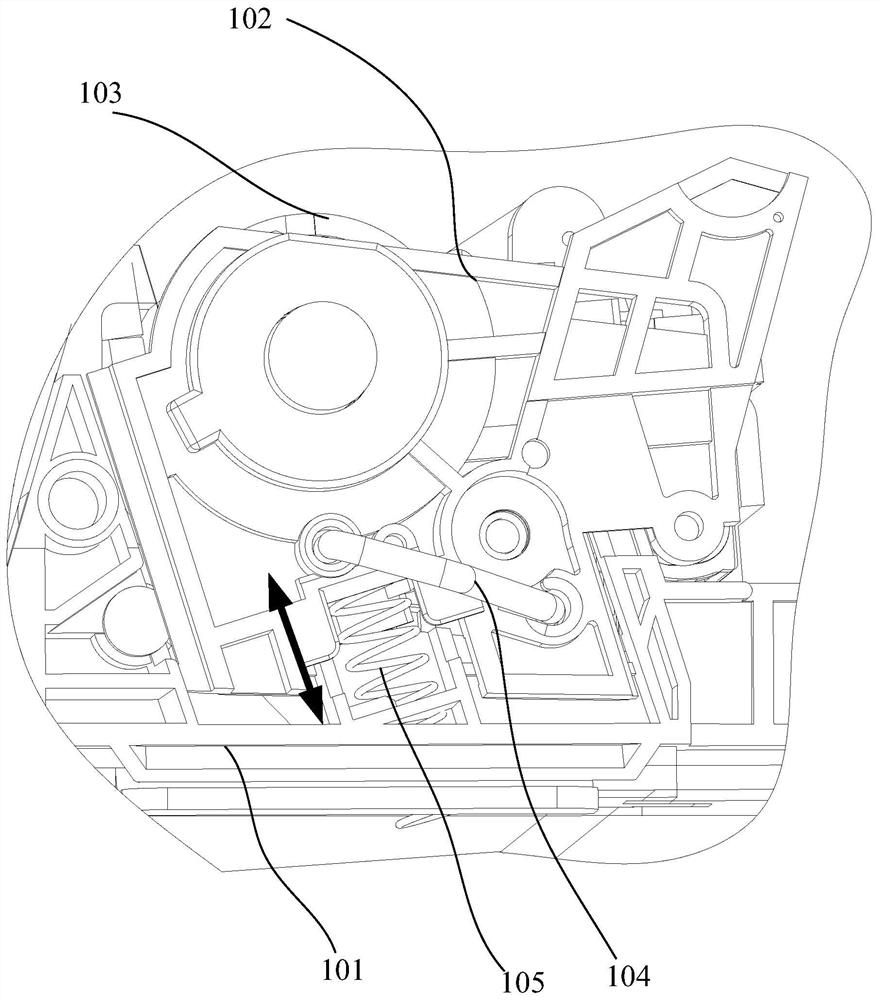

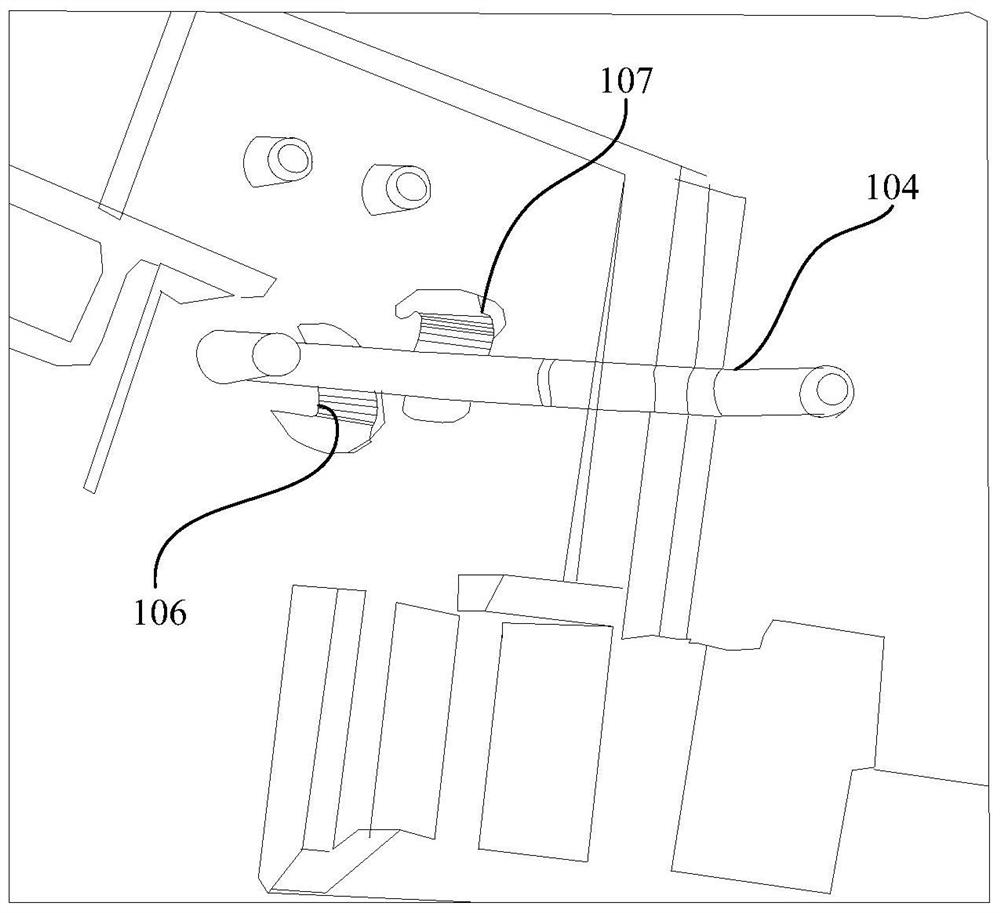

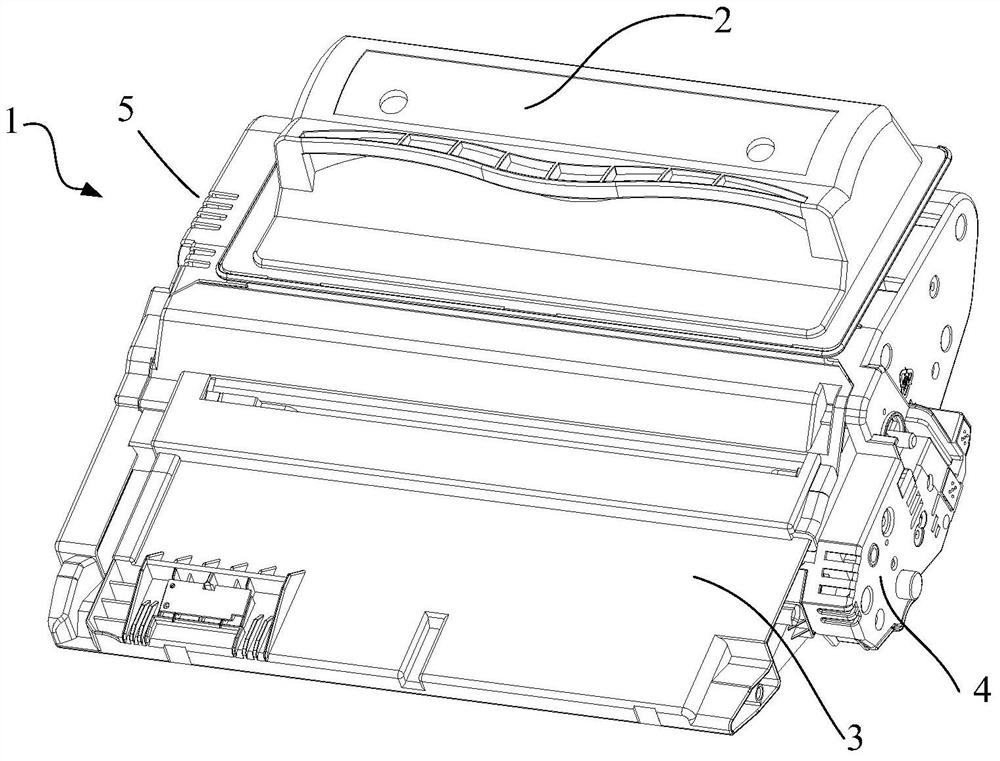

[0039] Such as image 3 , Figure 4 , Figure 5 As shown, the process cartridge 1 for an image forming apparatus provided by the present invention includes: a photosensitive element, which is composed of a photosensitive drum 7; a developing element, which is used to form an electrostatic latent image on the photosensitive element, and the present invention is preferably a magnetic roller 6; The first frame is provided with a storage chamber for accommodating the developer, the storage chamber is also called the powder bin 2, the first frame is provided with a developing element installation unit, the present invention is preferably a magnetic roller installation unit 60; and the present invention is preferably The first frame is composed of a powder bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com