Photovoltaic module

A photovoltaic module and light technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of inability to reflect light of specific wavelengths, easy aging of metal films, unfavorable promotion of photovoltaic integration, etc., and achieve selective transmission , Improve the effect of photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

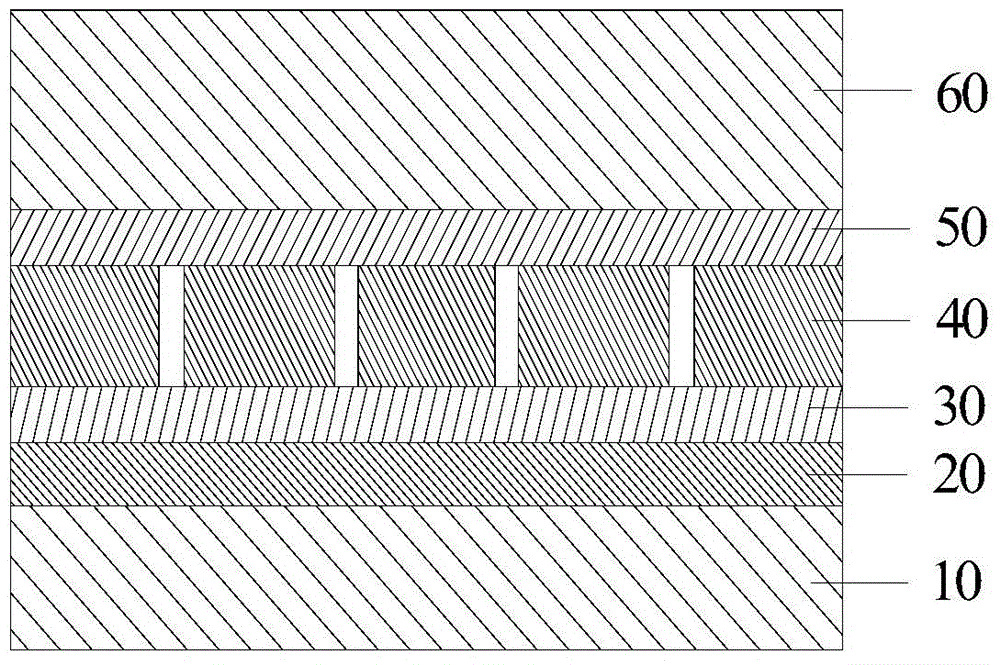

[0036] This embodiment provides a photovoltaic module, which includes a transparent backplane, and a selective light transmission film stacked on the photovoltaic backplane, a first encapsulation layer, a solar cell, a second encapsulation layer and a transparent layer, wherein, The selective light transmission coating consists of a layer of dielectric AR coating.

[0037] Among them, the material of the transparent backplane is calendered non-coated glass (produced by Ancai Hi-Tech), with a thickness of 3.2mm and a refractive index of 1.513; the material of the dielectric AR coating is TiO 2 , and the thickness is 75nm, and the refractive index is 2.52; the material of the first encapsulation layer is polyethylene-vinyl acetate (English abbreviation EVA, produced by Foster, the model is S501), and its refractive index is 1.48; the solar cell is Monocrystalline silicon cells with double-sided power generation (produced by Yingli, the series is Yingli Panda), and the spacing be...

Embodiment 2

[0039] This embodiment provides a photovoltaic module, which includes a transparent backplane, and a selective light transmission film stacked on the photovoltaic backplane, a first encapsulation layer, a solar cell, a second encapsulation layer and a transparent layer, wherein, The light-transmitting film is selected as a three-layer dielectric anti-reflection film sequentially arranged on the transparent backplane.

[0040] Among them, the material of the transparent backplane is calendered non-coated glass (produced by Ancai Hi-Tech), with a thickness of 3.2mm and a refractive index of 1.513; the materials of the three-layer dielectric antireflection film are 78nm in thickness, 78nm in thickness, AlN with a refractive index of 1.78, Al with a thickness of 315nm and a refractive index of 1.596 2 o 3 , and TiO with a thickness of 75 nm and a refractive index of 2.52 2 The material of the first encapsulation layer is polyethylene-vinyl acetate (English abbreviation EVA, prod...

Embodiment 3

[0042] This embodiment provides a photovoltaic module, which includes a transparent backplane, and a selective light transmission film stacked on the photovoltaic backplane, a first encapsulation layer, a solar cell, a second encapsulation layer and a transparent layer, wherein, The light-transmitting film is selected as two layers of dielectric anti-reflection films sequentially arranged on the transparent backplane.

[0043] Among them, the material of the transparent backplane is calendered non-coated glass (produced by Ancai Hi-Tech), and the thickness is 3.2mm, and the refractive index is 1.513; Al with a refractive index of 1.596 2 o 3 , and TiO with a thickness of 275 nm and a refractive index of 2.52 2 The material of the first encapsulation layer is polyethylene-vinyl acetate (English abbreviation EVA, produced by Foster, model is S501), and the refractive index is 1.48; production, the series is Yingli Panda), and the spacing between cells is 20mm, and the spacing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com