Preparation method of lithium manganate material and method for preparing battery from lithium manganate material

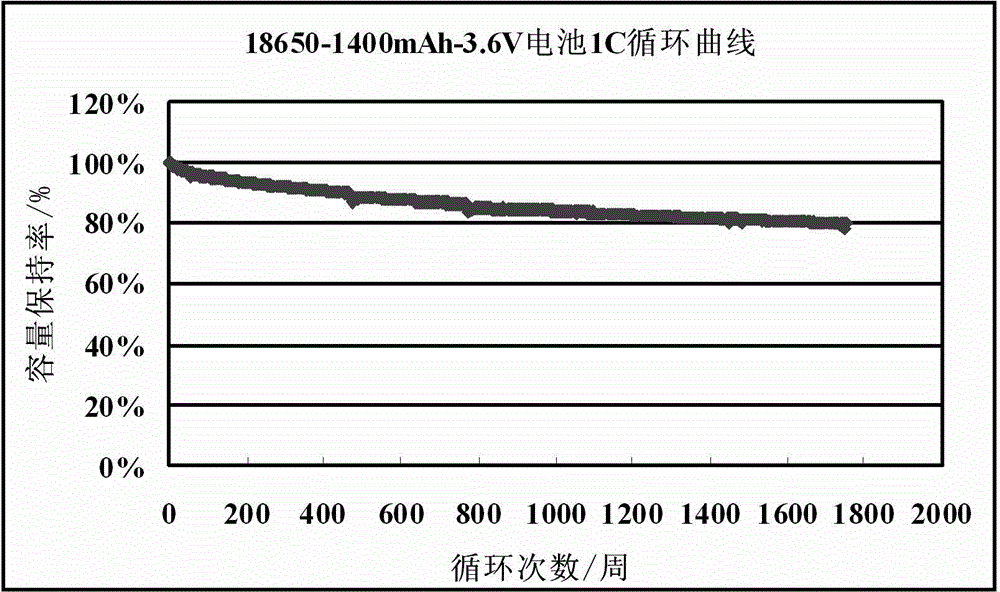

A lithium manganate and the technology of lithium manganate are applied to the preparation method of lithium ion battery materials and the field of batteries prepared from the material, which can solve the problems of poor normal temperature cycle performance of lithium manganate materials, achieve excellent abnormal temperature cycle performance, and improve consistency. The effect of shortening the stirring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of positive electrode: LiMn 2 O 4 / Carbon nanotubes: Super-P:KS-6:PVDF:NMP=89:3:3:5:45; first dissolve PVDF in NMP, stir for 3h, then add LiMn 2 O 4 After the carbon nanotube composite material and the conductive agent are mixed, the dry powder mixer is used to uniformly disperse and stir, the spindle speed is 23r / min, and the stirring time is 90min. Then add the mixed material into the glue solution, stir at high speed for 4h for dispersion, the low speed revolution speed is 18r / min, the high speed dispersion speed is 2200r / min, and the vacuum degree is -0.095MPa. The stirred slurry is vacuum defoamed and then sieved for coating, dried, rolled, and slit to obtain a positive electrode sheet.

[0024] Preparation of negative electrode: MCMB:Super-P:CMC:SBR:H 2 O=94:2:1.5:2.5:118. First dissolve the CMC in deionized water, stir for 2~3h, then mix the mesocarbon microspheres and the conductive agent, then use a dry powder mixer to evenly disperse and stir, the spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com