Method and device for controlling power-on flow of multi-branch battery energy storage system

A battery energy storage system, energy storage system technology, applied in battery circuit devices, circuit devices, secondary battery charging/discharging, etc., can solve the problem of system reliability reduction, affecting the rescue effect, and the reliability of lithium-ion battery energy storage systems. Reduced performance and other issues, to improve reliability and system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

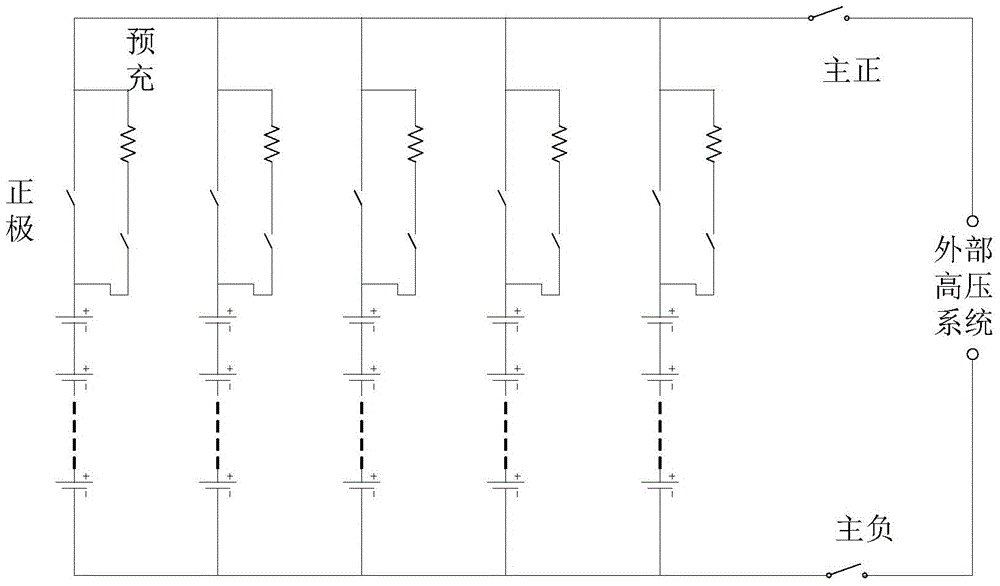

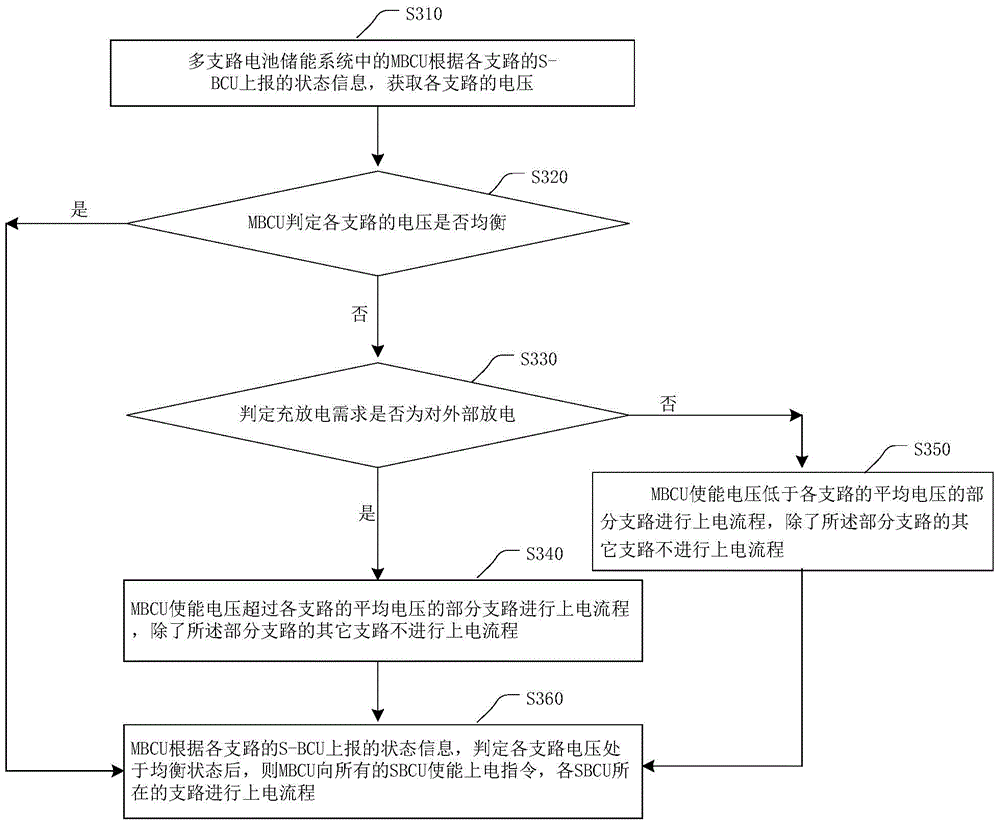

[0044] The schematic structural diagram of a lithium-ion battery energy storage system provided in this embodiment is as follows: figure 1 As shown, the lithium-ion battery energy storage system is composed of several branches connected in parallel, each branch is composed of several groups of battery modules connected in series, and the battery modules are composed of battery cells connected in series and parallel. Each branch has an independent relay and pre-charging equipment. After the branch is connected in parallel, it is connected to the external high-voltage system through two relays, the main positive and the main total negative. When different branches are in a state of voltage balance, each branch needs to complete the power-on action. When each branch is in an unbalanced state before power-on, the system obtains the current charging and discharging demand through the man-machine interface, and determines the power-on process of the branch according to the charging ...

Embodiment 2

[0062] When the MBCU determines that a branch is faulty based on the status information reported by the S-BCU of each branch, it will issue a zero power request to the external high-voltage system, and disconnect the relay of the faulty branch after reaching zero power, and a fault will occur branch removed. Since each branch is in parallel state, removing the failed branch will not affect other branches. After removing the faulty branch, restore the charging and discharging power of the system.

Embodiment 3

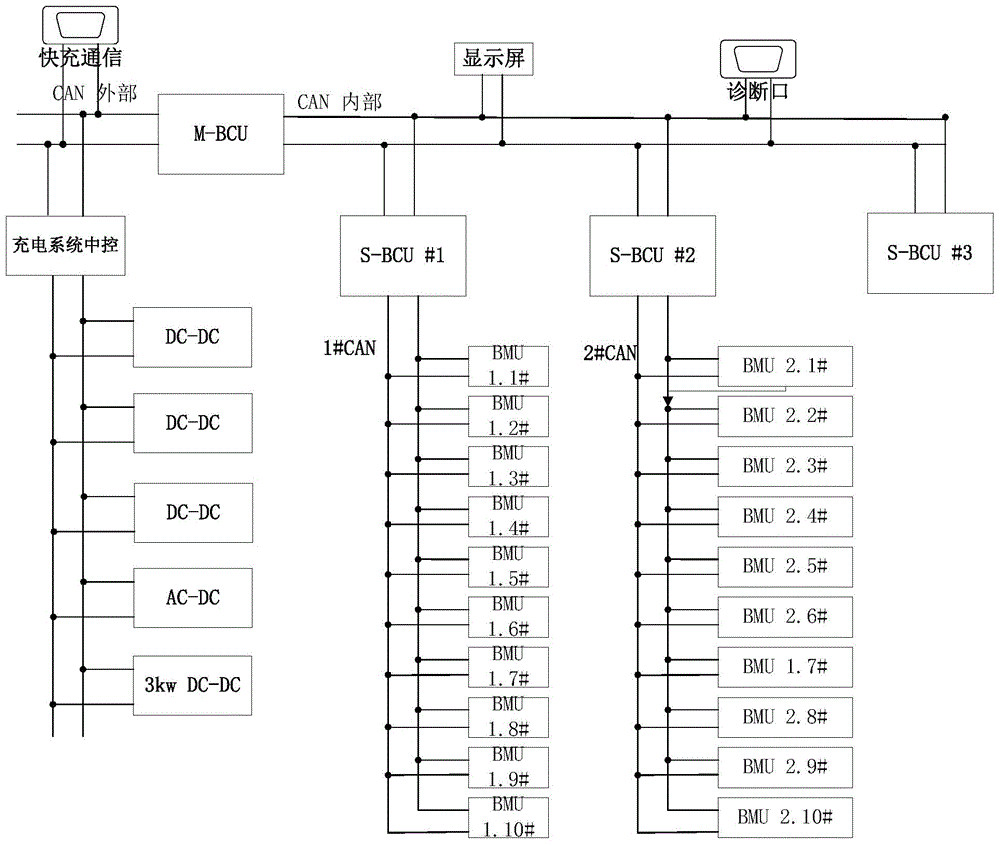

[0064] A schematic structural diagram of a power-on process control device for a multi-branch battery energy storage system provided in this embodiment is as follows: Figure 4 As shown, including: MBCU41, S-BCU42 of each branch and BMU43 of each battery module;

[0065] The S-BCU41 of each branch is used to report the state information of each branch to the MBCU, and the state information includes the voltage of each branch;

[0066] The MBCU42 is used to obtain the voltage of each branch according to the state information reported by the S-BCU of each branch, and to obtain the current charge and discharge demand of the battery energy storage system when it is determined that the voltage of each branch is unbalanced; When the charge and discharge requirement is for external discharge, the power-on process is performed on some branches whose voltage exceeds the average voltage of each branch, and the other branches except the part of the branch do not perform the power-on proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com