Method applying wood rotting fungus dregs to industrial cultivation of agaricus bisporus

A technology for wood-rot fungus residue and Agaricus bisporus, which is applied in cultivation, plant cultivation, mushroom cultivation, etc., can solve the problems of pollution of the environment, waste of resources, growth of molds and pests, etc., so as to increase soil fertility and save time for fruiting. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

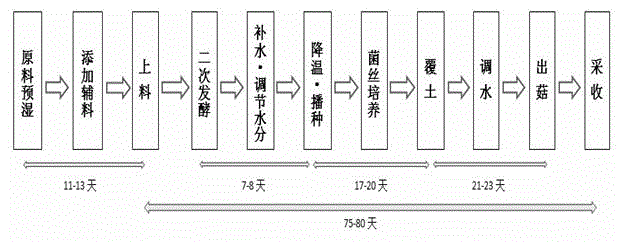

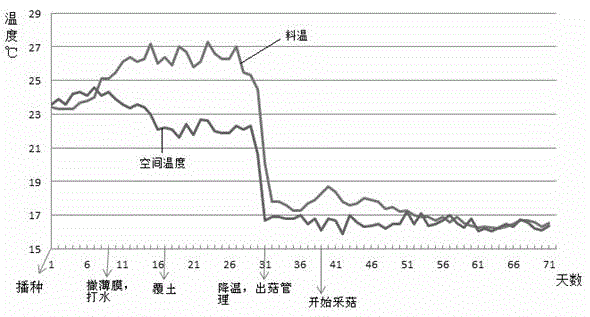

Method used

Image

Examples

Embodiment 1

[0037] 1.1 Medium formula:

[0038] ①Wood rot fungus residue 69%, cow dung 29%, salt 0.7%, superphosphate 0.4%, light calcium 0.4%, lime 0.5%.

[0039] ②Wood rot fungus residue 79%, cow dung 19%, salt 0.7%, superphosphate 0.4%, light calcium 0.4%, lime 0.5%.

[0040] 1.2 Primary fermentation (pre-fermentation)

[0041] Cultivate Agaricus bisporus by using wood rot fungus residue as raw material. After feeding, pre-wet the fungus residue, then evenly cover the fungus residue with cow dung, and continue to spray water to pre-wet until the cow dung is fully softened. Stop watering (about 3-4 days). For the first turning over, auxiliary materials need to be added to the slag: salt, superphosphate, light calcium. After that, turn the pile once every 3 days, and load the material after turning the pile 3 times. Sprinkle lime evenly on the surface before loading.

[0042] 1.3 Secondary fermentation (post-fermentation)

[0043] After the pre-fermentation, the water content...

Embodiment 2

[0057] The compost formula is: 98.5% of wood rot fungus residue, 0.6% of salt, 0.3% of superphosphate, 0.3% of light calcium, and 0.3% of lime. All the other steps are the same as in Example 1.

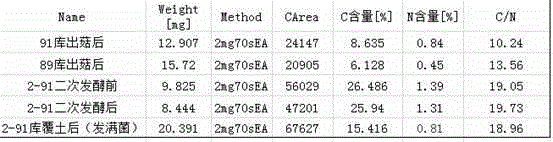

[0058] During the cultivation process, we tested the C and N content in some periods, and the test results are as follows:

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com