Greenhouse lighting supplementing and shading system reconstructed of waste LCDs (liquid crystal displays)

A shading system and liquid crystal screen technology, which is applied in greenhouse cultivation, climate change adaptation, gardening, etc., can solve problems such as insufficient light and impact on agricultural production, and achieve the effects of increased light intensity, considerable economic benefits, and more fruit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

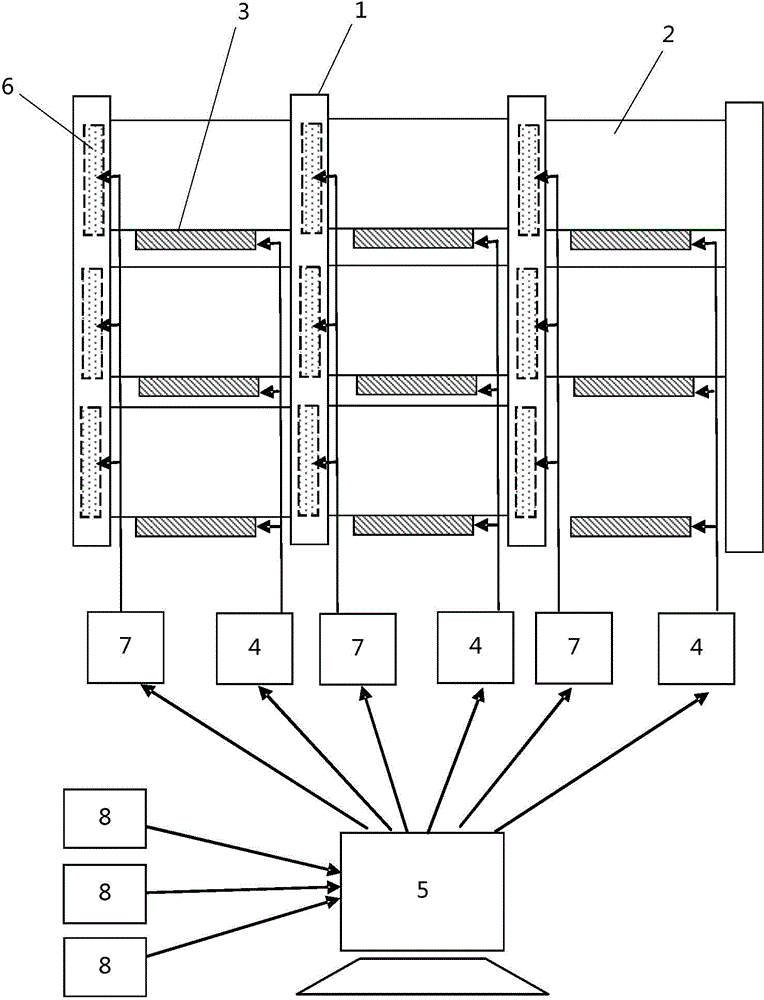

[0014] After research, it is found that most of the waste LCD screens have only some damaged pixels, while their drive and backlight systems are intact, which can continue to play a role in the field of greenhouse farming. After the waste LCD screen is recycled, it is disassembled to remove the base, plastic shell and light guide plate, and then decomposed into LCD screen, driver board, power supply, side light and other parts. see figure 1 , the upper part of which is the plan view of the top of the greenhouse, install the LCD screen 2 on the bracket 1 on the top of the greenhouse; install the LCD driver board 3 on the bracket 1 below the LCD screen 2, and install the power supply of the LCD screen on the bracket 1 On the back side of the backside, the video lines of the LCD driver board 3 converge on the video distributor 4 through the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com