Patents

Literature

141results about How to "Huge market" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

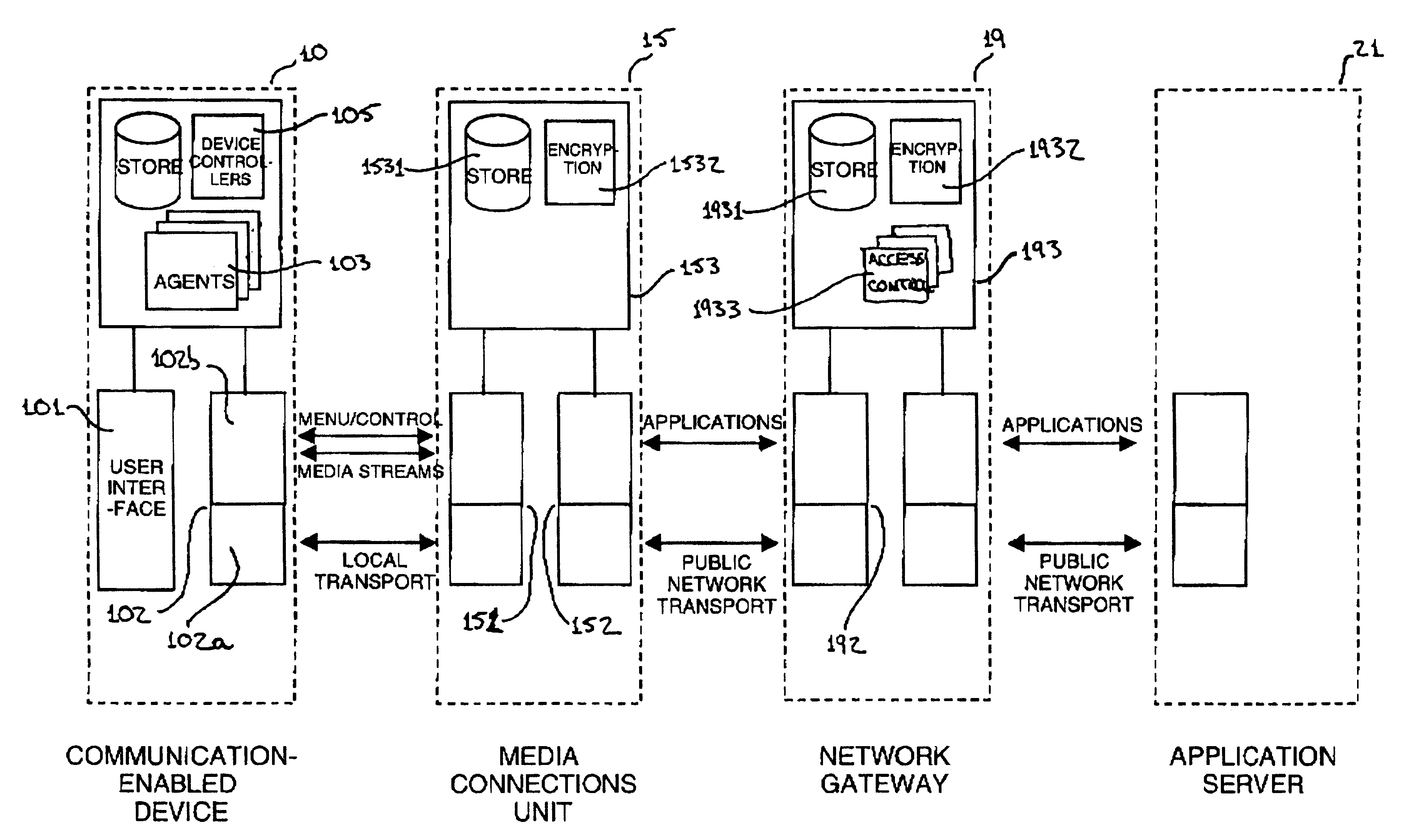

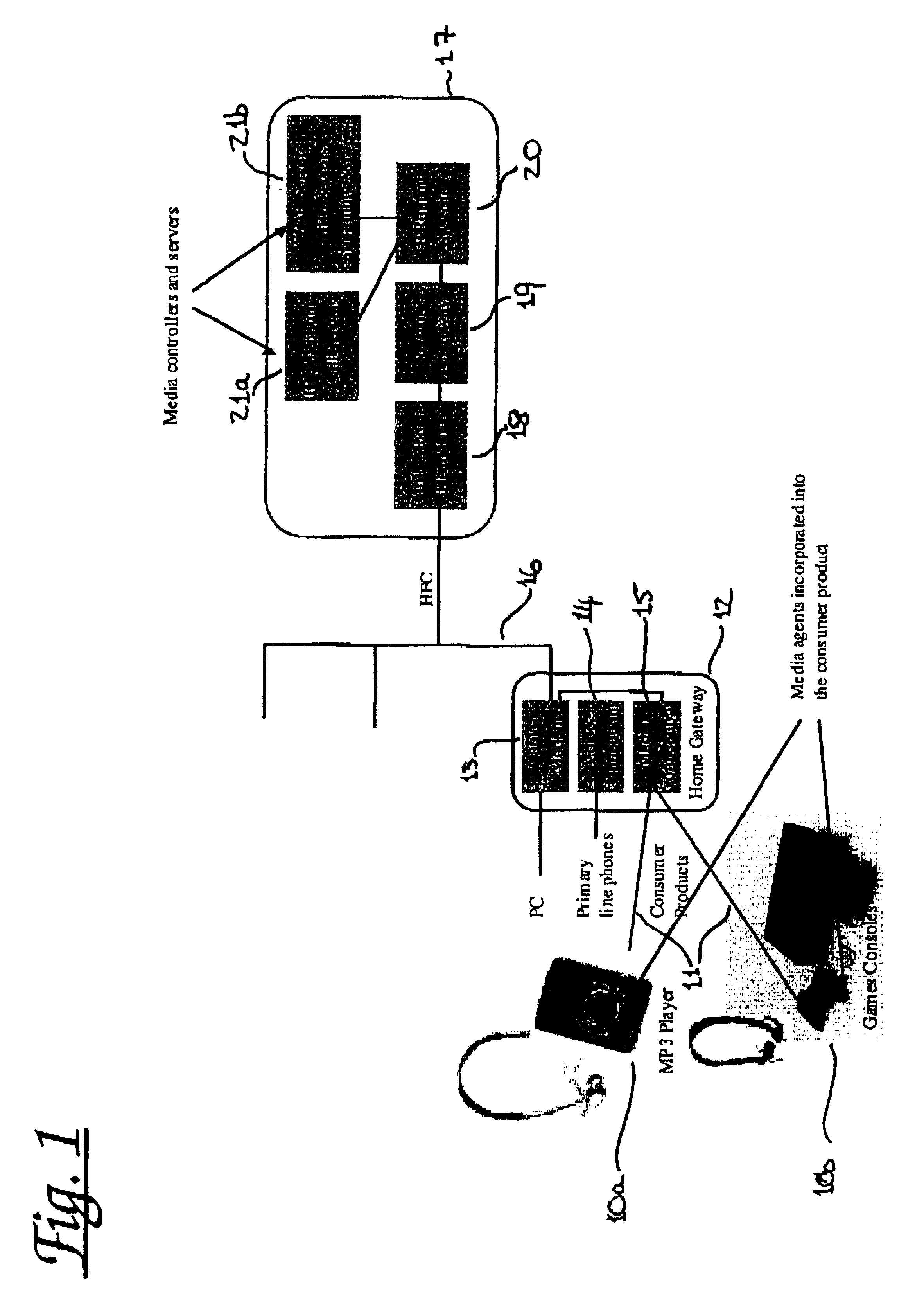

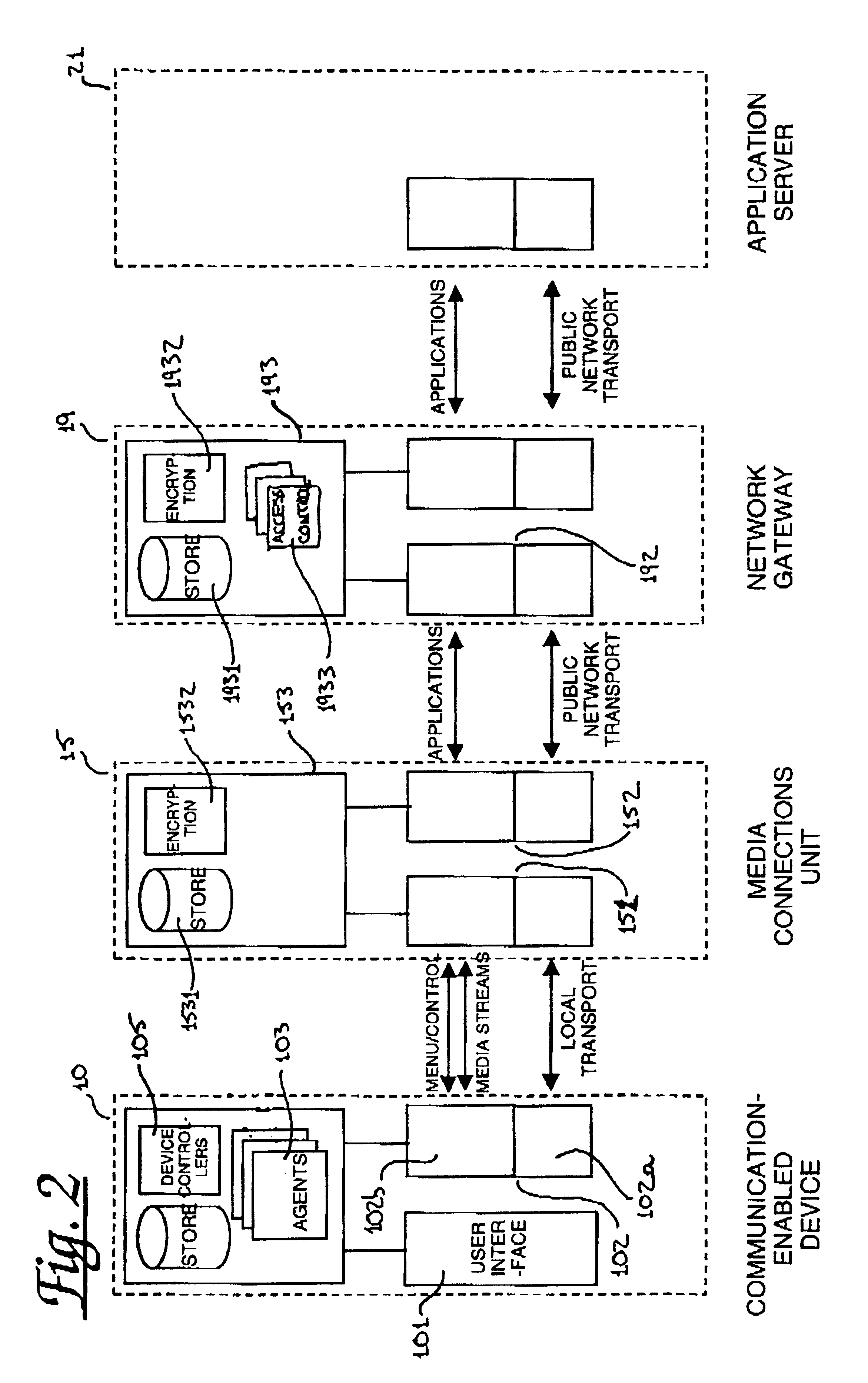

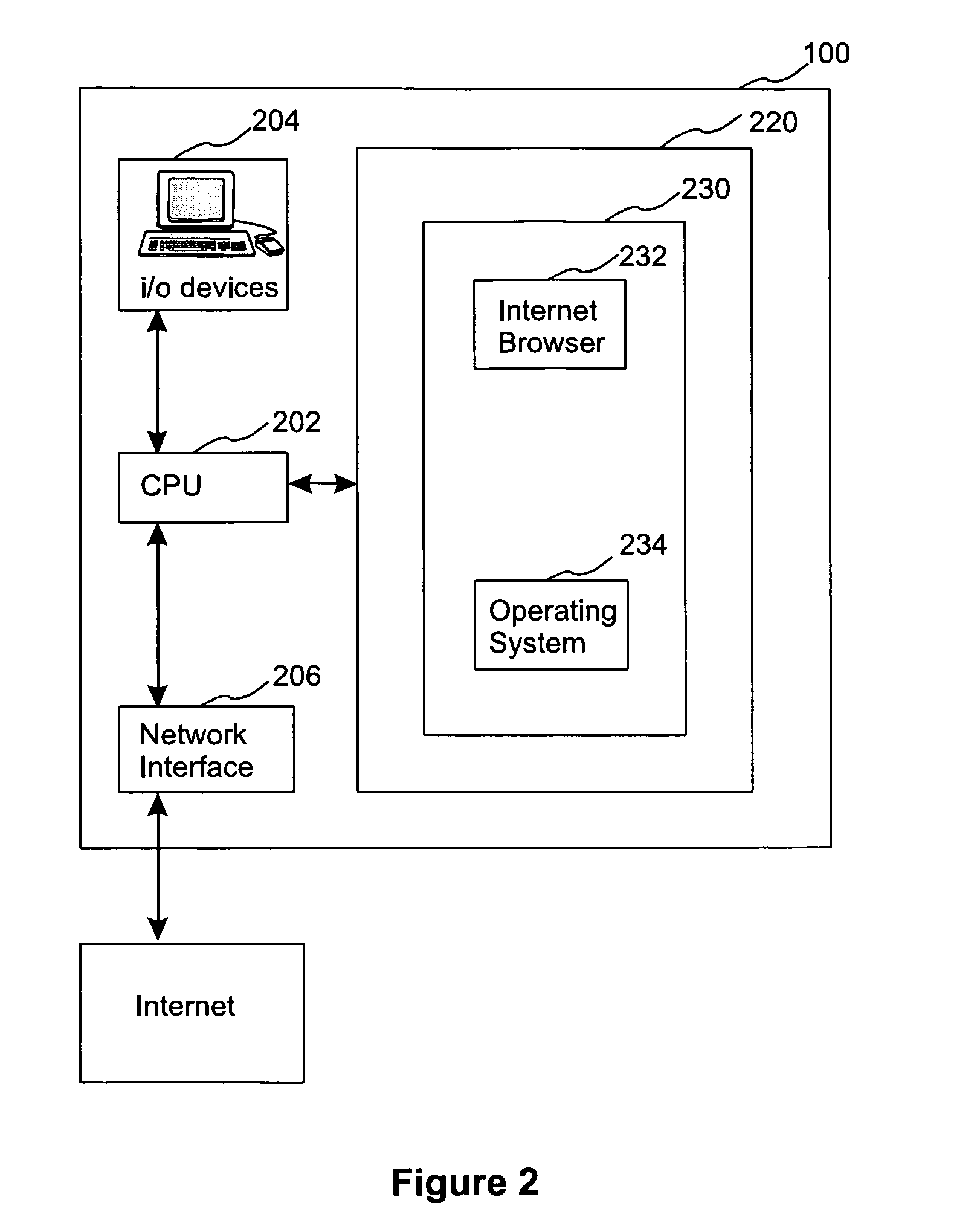

Communication enabled consumer products and controller

A consumer entertainment device (for example, a games console, audio recording player, radio frequency broadcast reception apparatus) comprising a telecommunications transceiver arranged for communication over a customer premises network. The device may also comprise telephony handset apparatus, making shared use with the entertainment control apparatus of the telecommunications transceiver. Also a media connections unit arranged to inter-work between such a consumer entertainment device and a public network. Additionally, a network gateway comprising an access control unit whereby to control access to a network from a remote media connections unit.

Owner:MICROSOFT TECH LICENSING LLC

Nicotine-alternative compositions and methods of producing such compositions

InactiveUS20060204598A1Eliminate needLess-expensive to produceOrganic active ingredientsBiocideNicotine replacementAlkaloid

A method for producing a consumable nicotine-alternative composition includes measuring a quantity of a cigarette nicotine-alternative alkaloid and / or a larger quantity of lobeline. The quantities of cigarette nicotine-alternative alkaloid and / or lobeline are diluted into one or more successive intermediate solutions, a last of which constitutes a final solution. The final solution is apportioned so that each portion contains a precise quantity of cigarette nicotine-alternative alkaloid and / or lobeline appropriate for consumption in a single use by a single person. Each portion is introduced into a separate single-serving dispenser.

Owner:THOMPSON MARSHALL ANLAUF

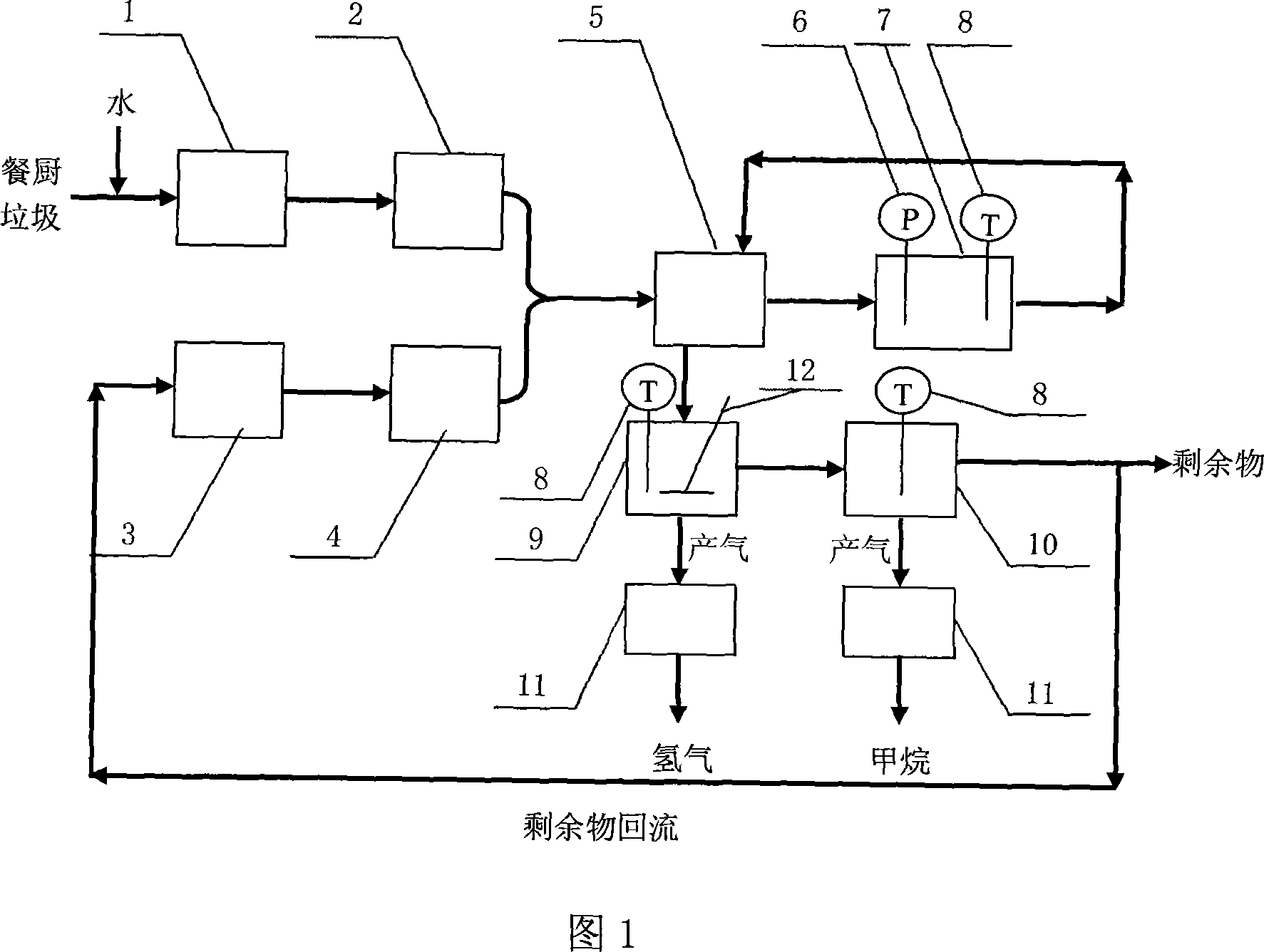

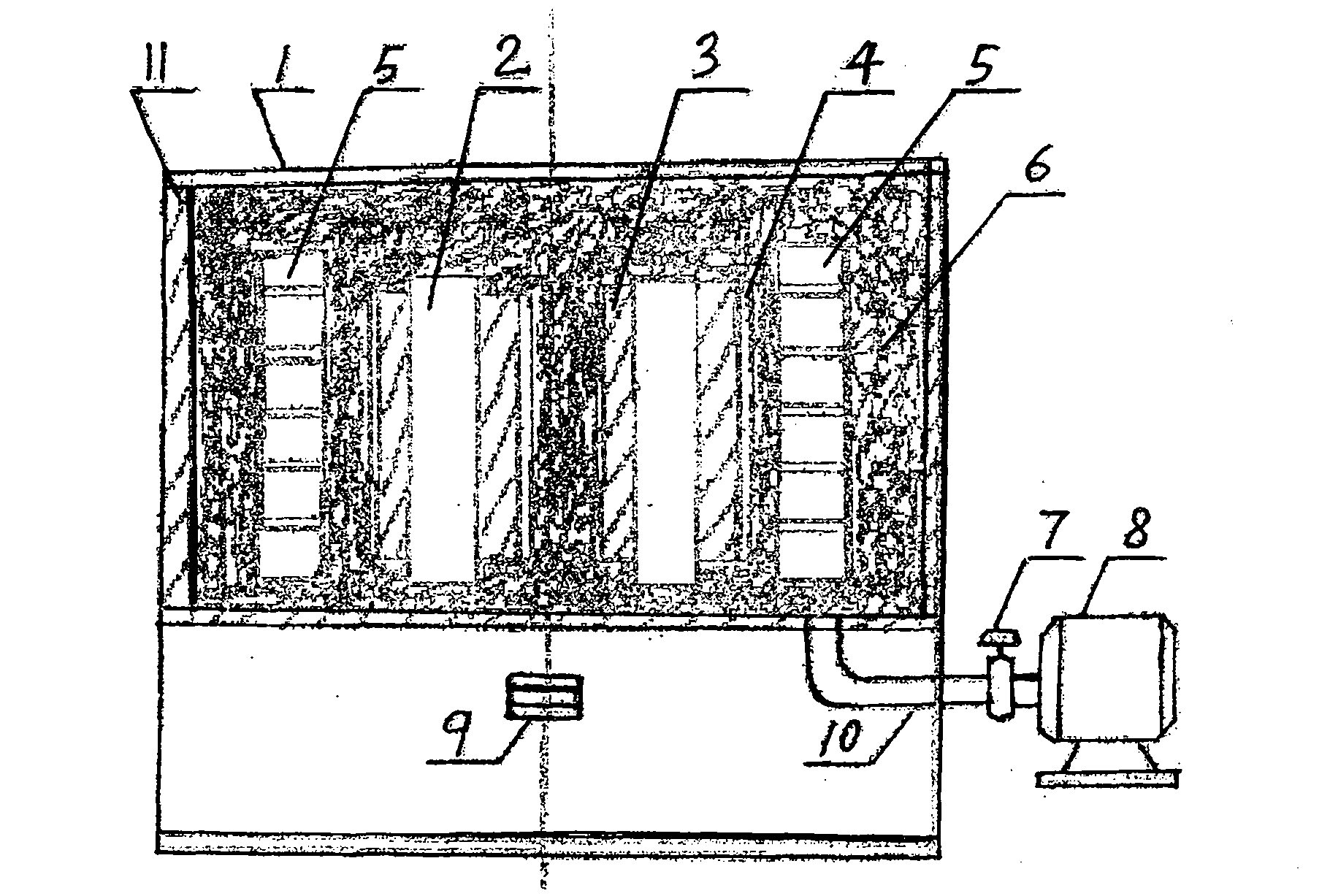

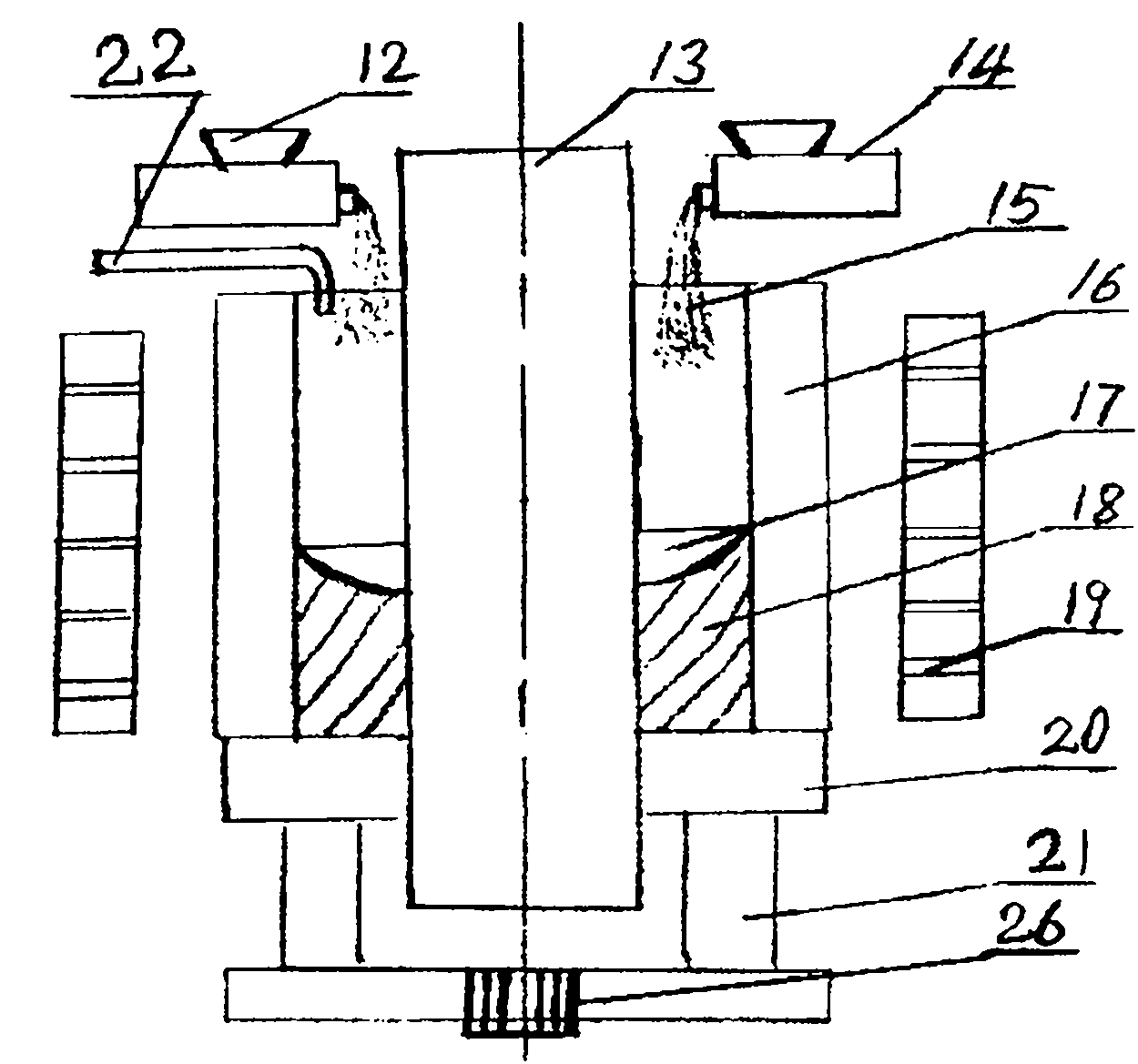

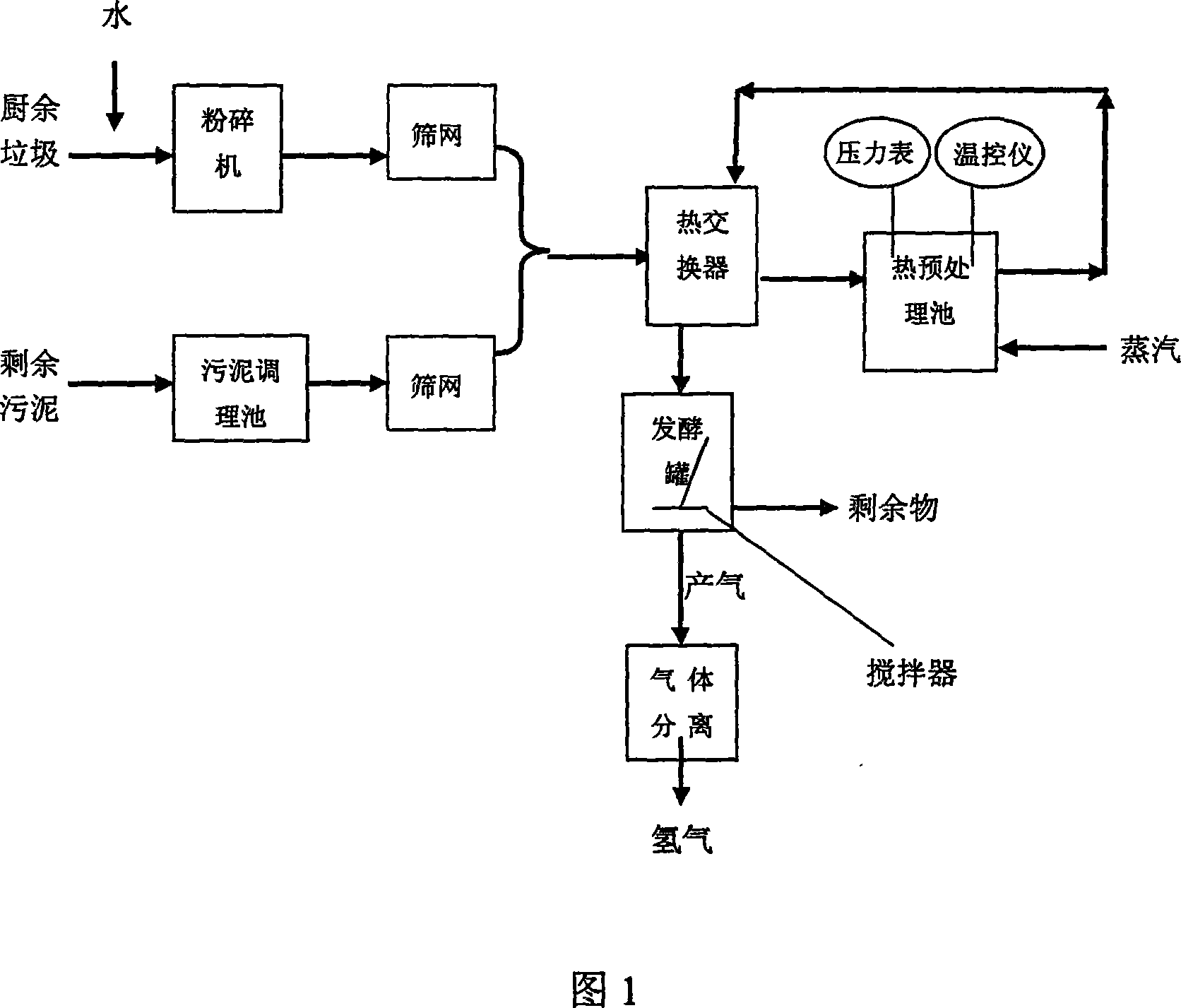

Method for producing hydrogen and methane by kitchen waste diphasic anaerobic fermentation

InactiveCN101134684APH controlLow running costBio-organic fraction processingClimate change adaptationHydrogenSludge

The biphase anaerobic fermentation process of kitchen refuse to produce hydrogen and methane includes the following steps: 1. sorting kitchen refuse and mixing with water in certain amount; 2. mixing with sludge from sewage treating yard and heat treatment; 3. heat exchange between heat treated mixture and mixture without through heat treatment; 4. anaerobic fermentation of the heat treated mixture in the first phase to produce hydrogen; 5. anaerobic fermentation of the residue from the first phase fermentation in the second phase to produce methane; and 6. using the residue from the second phase fermentation as fertilizer or returning to replace sludge serving as hydrogen producing bacteria source. The process is simple, can recover the biomass energy from kitchen refuse effectively, and has no secondary pollution.

Owner:DONGGUAN KECHUANG FUTURE ENERGY SOURCE TECHDEV

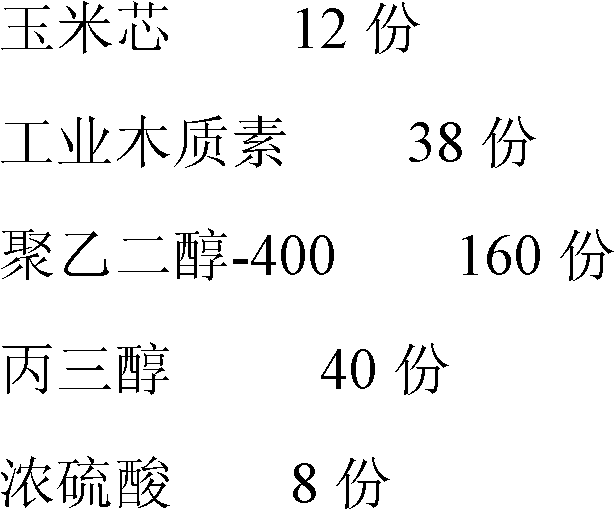

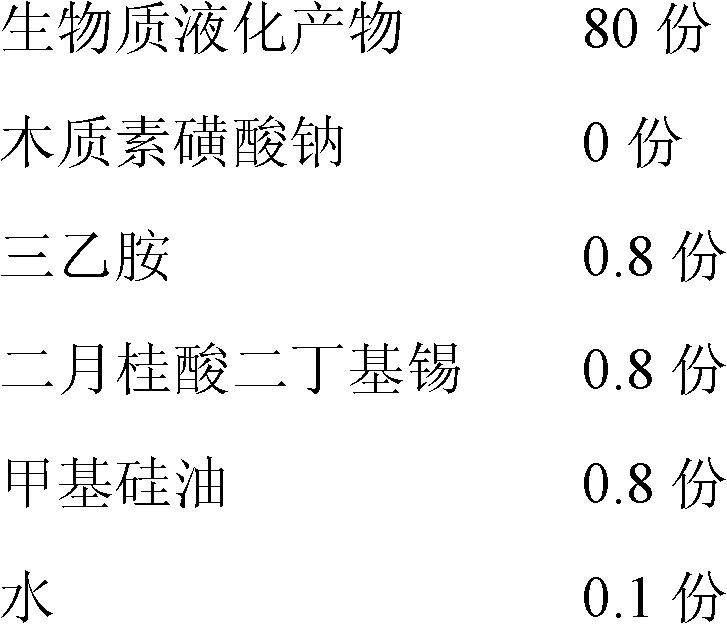

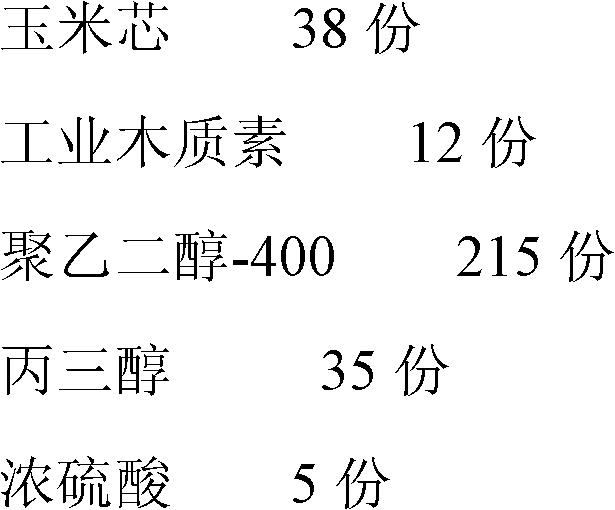

Preparation method of biomass-base polyurethane foam material

The invention discloses a preparation method of a biomass-base polyurethane foam material, belonging to the technical field of chemical industry. The method mainly comprises the following steps: mixing polybasic alcohol liquefier and liquefying catalyst, putting the mixture in a container, heating to 150-200 DEG C, adding biomass waste and industrial lignin, liquefying, and cooling to room temperature to obtain a biomass liquefied product; and mixing the prepared biomass liquefied product, foaming catalyst, foam stabilizer, foaming agent and lignosulphonate into a component A, using isocyanate as a component B, mixing the component A and component B in a mixing vessel, stirring at 20-40 DEG C at 8000-14000 rpm for 5-30 seconds, pouring the mixture into a die, naturally foaming for 5-60 seconds, standing at 80-120 DEG C for 8-24 hours, and storing at room temperature for 8-24 hours until the mixture is sufficiently aged and formed. The invention can obviously improve the properties of the biomass-base polyurethane foam.

Owner:CHINA AGRI UNIV

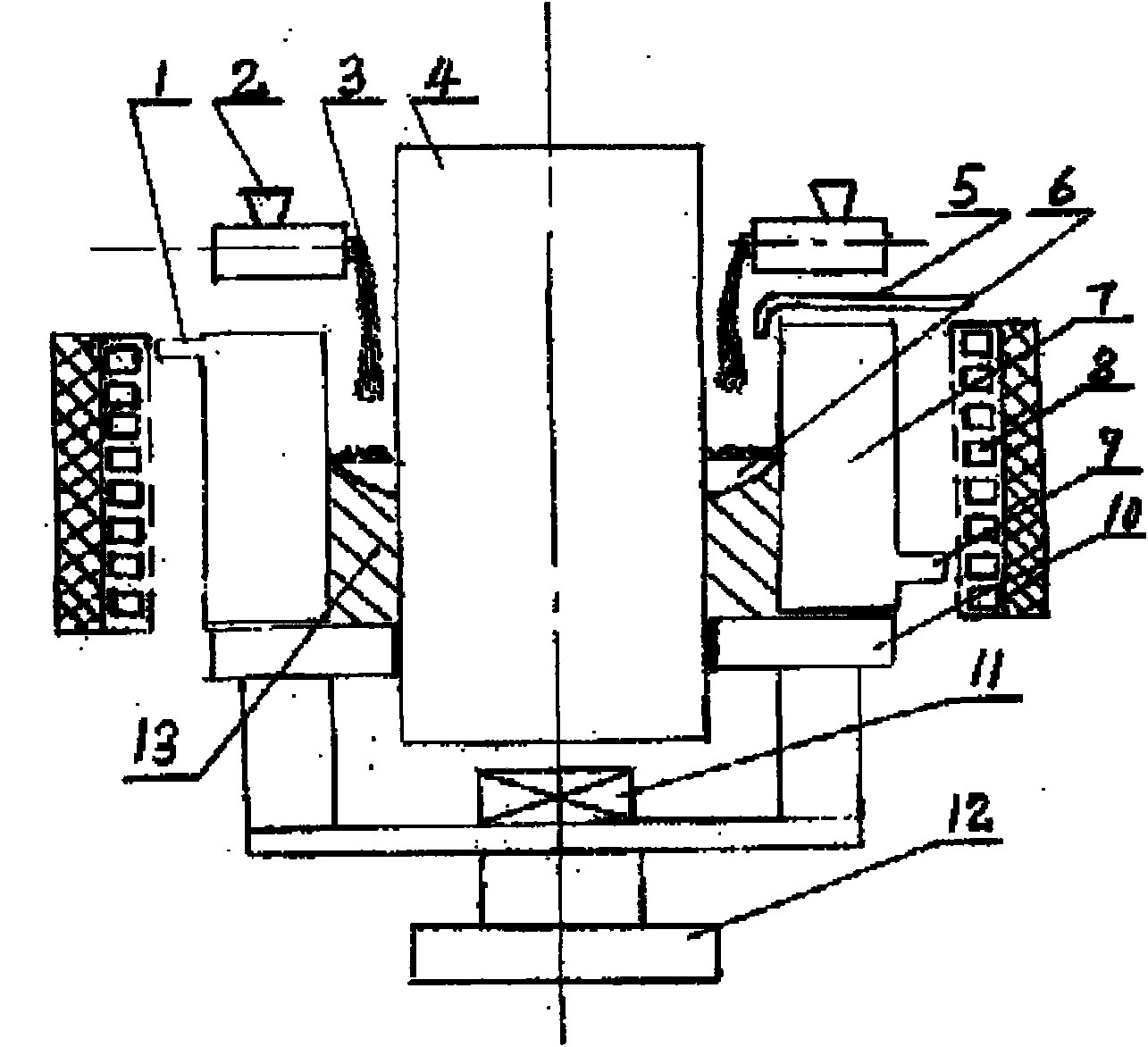

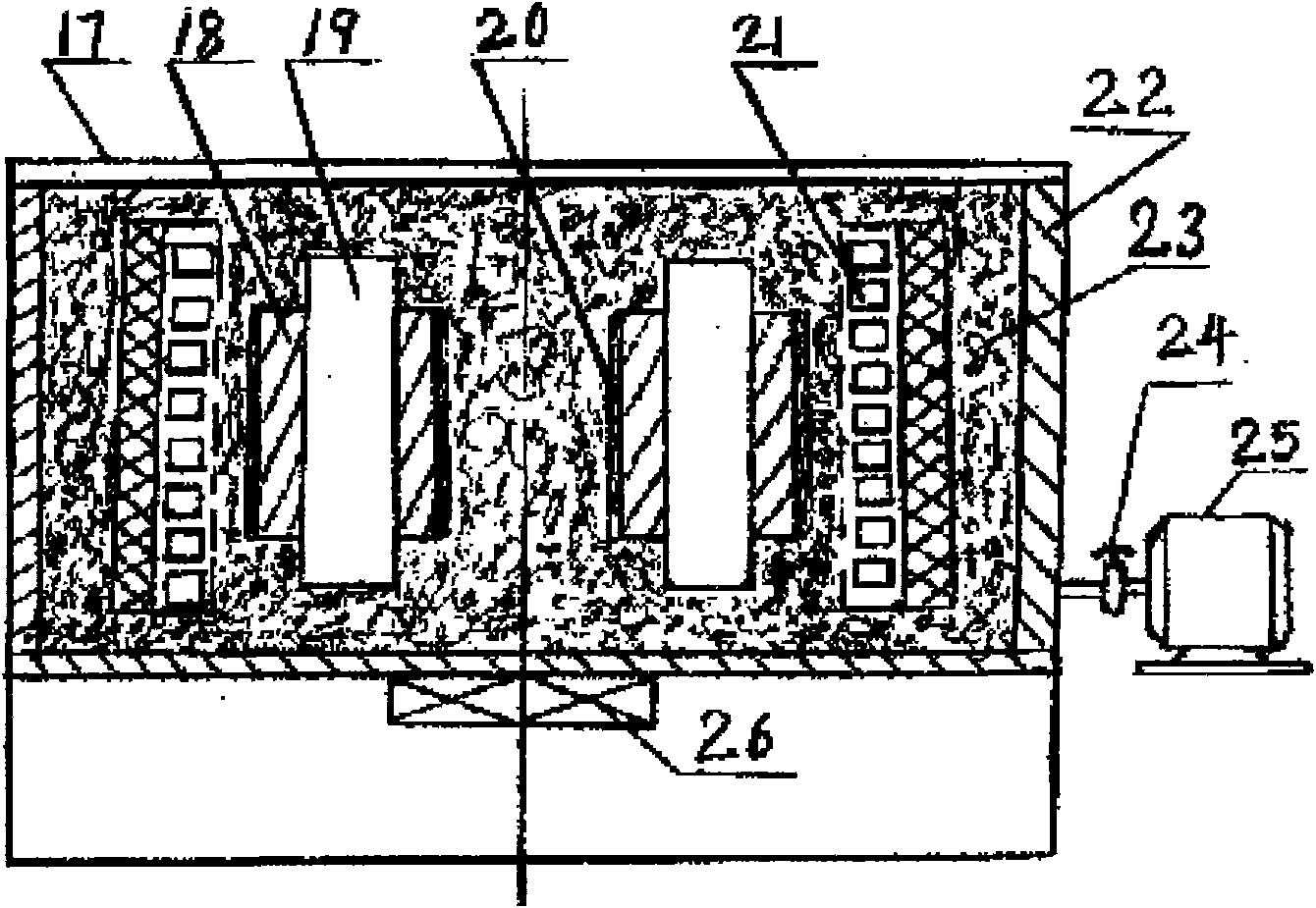

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

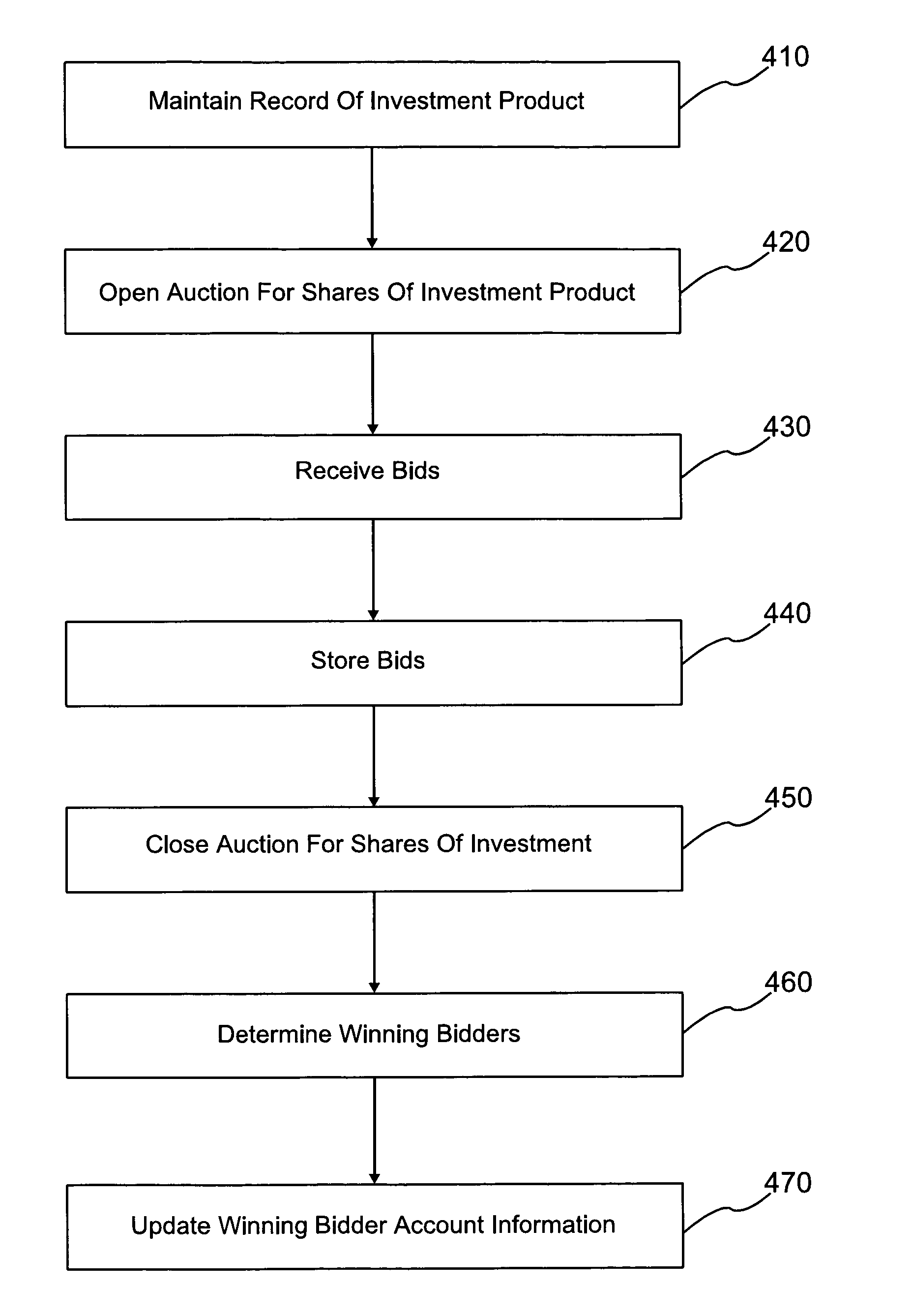

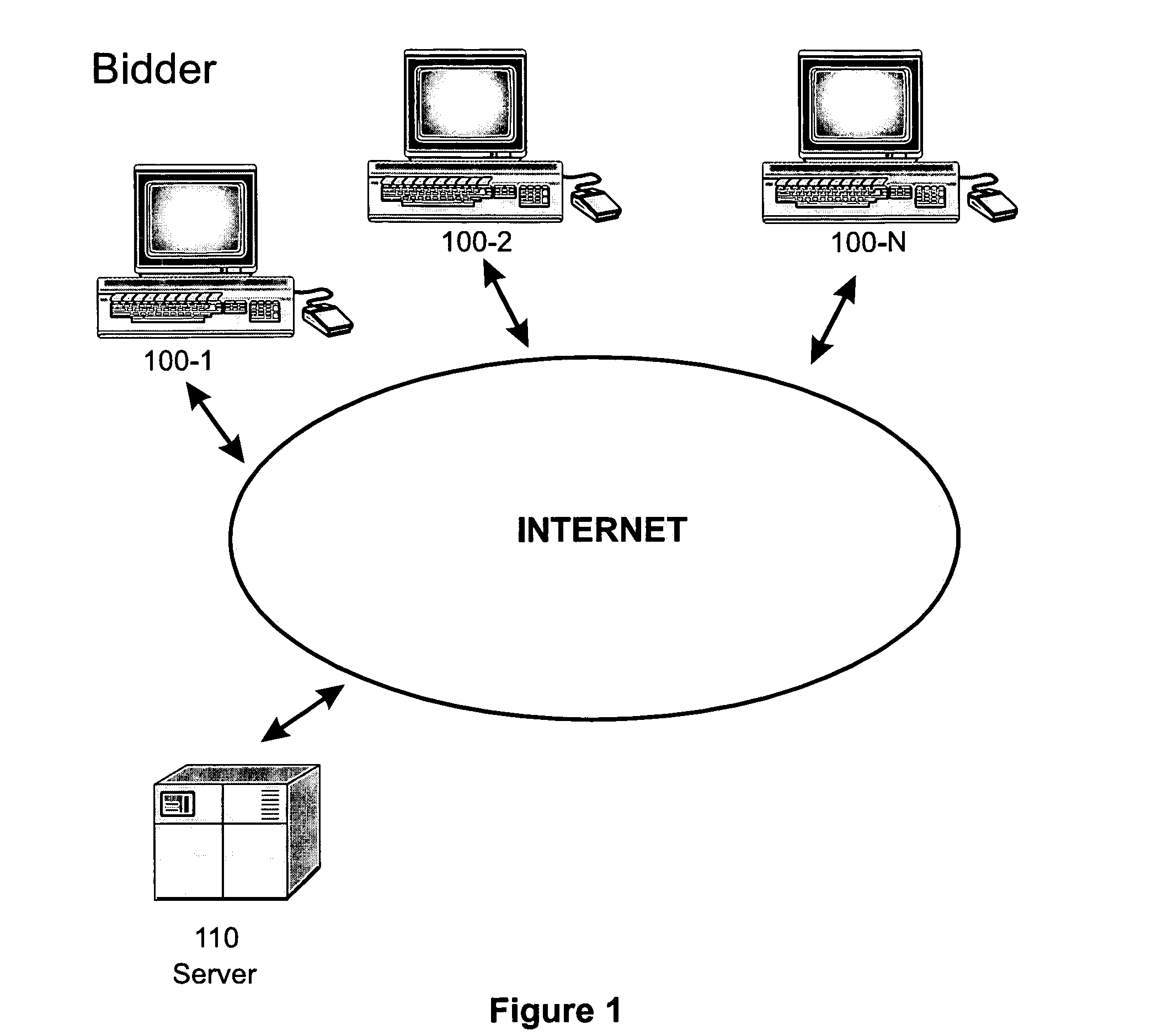

Communication network based system and method for auctioning shares on an investment product

A communication network based system and method for auctioning shares of investment product is disclosed. In the preferred embodiment, an investment company pursuant to the Investment Company Act of 1940, creates a publicly registered investment product (e.g., a mutual fund) with its own capital and as sole shareholder. After the investment product returns a pre-determined hurdle rate, or rate of return, the investment company then preferably liquidates its investment position in the investment product in order to freeze the net asset value of the shares of the mutual fund. The investment product is later opened for auction and the server system receives and stores bids from a plurality of bidders, in increments up to the net asset value. The bids preferably comprise a bid price per share and the number of shares bid. At the close of the auction, the server system preferably determines winning bidders by successively determining the highest bidder. During this process, the server system reduces the total number of available shares to be distributed by the number of shares bid by the highest bidder. Once all of the available shares have been allocated to the winning bidders, the investment product shares are redeemed at the net asset value reflecting the hurdle rate. Each of the winning bidders is receives a return equal to the difference between the net asset value and the respective winning bidders' bid price per share multiplied by the number of shares bid by each respective winning bidder.

Owner:PODSIADLO EUGENE LAWRENCE

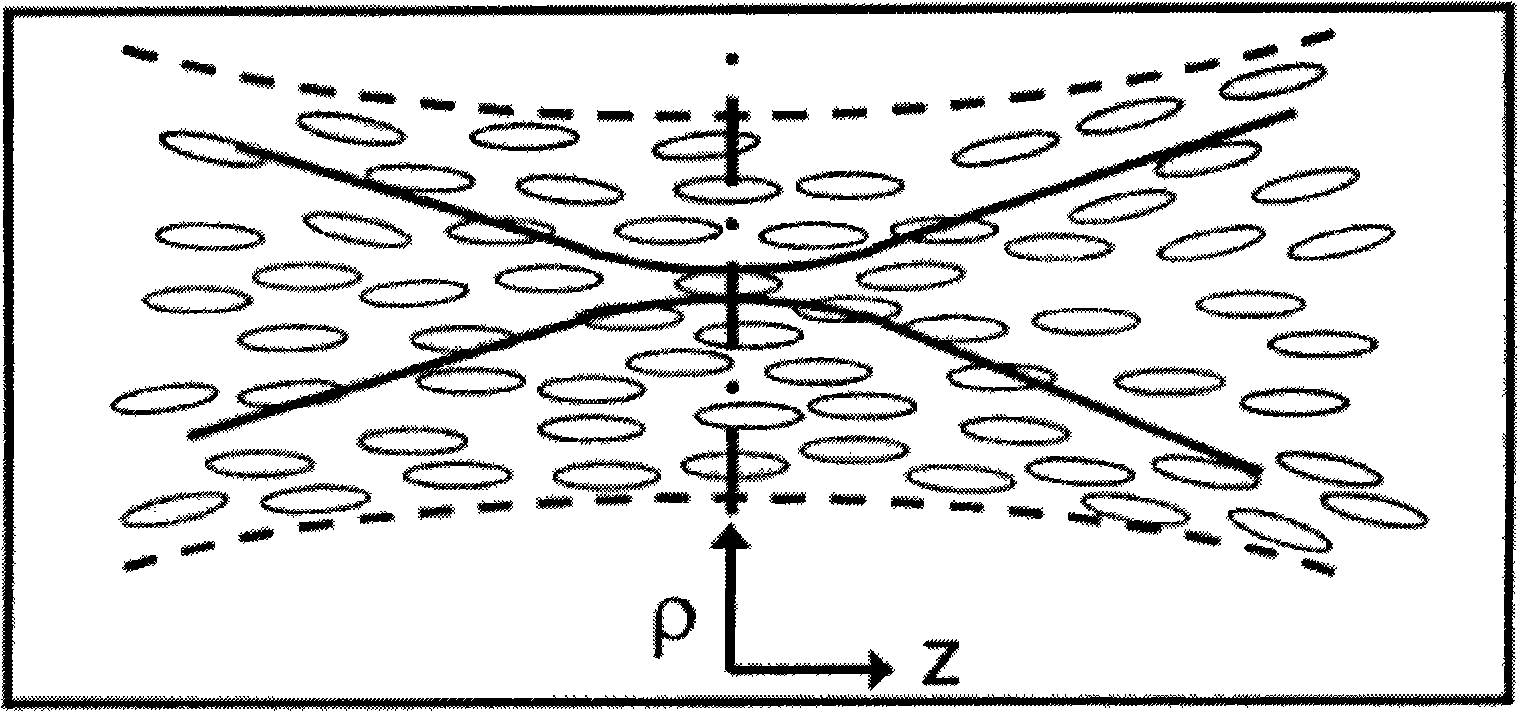

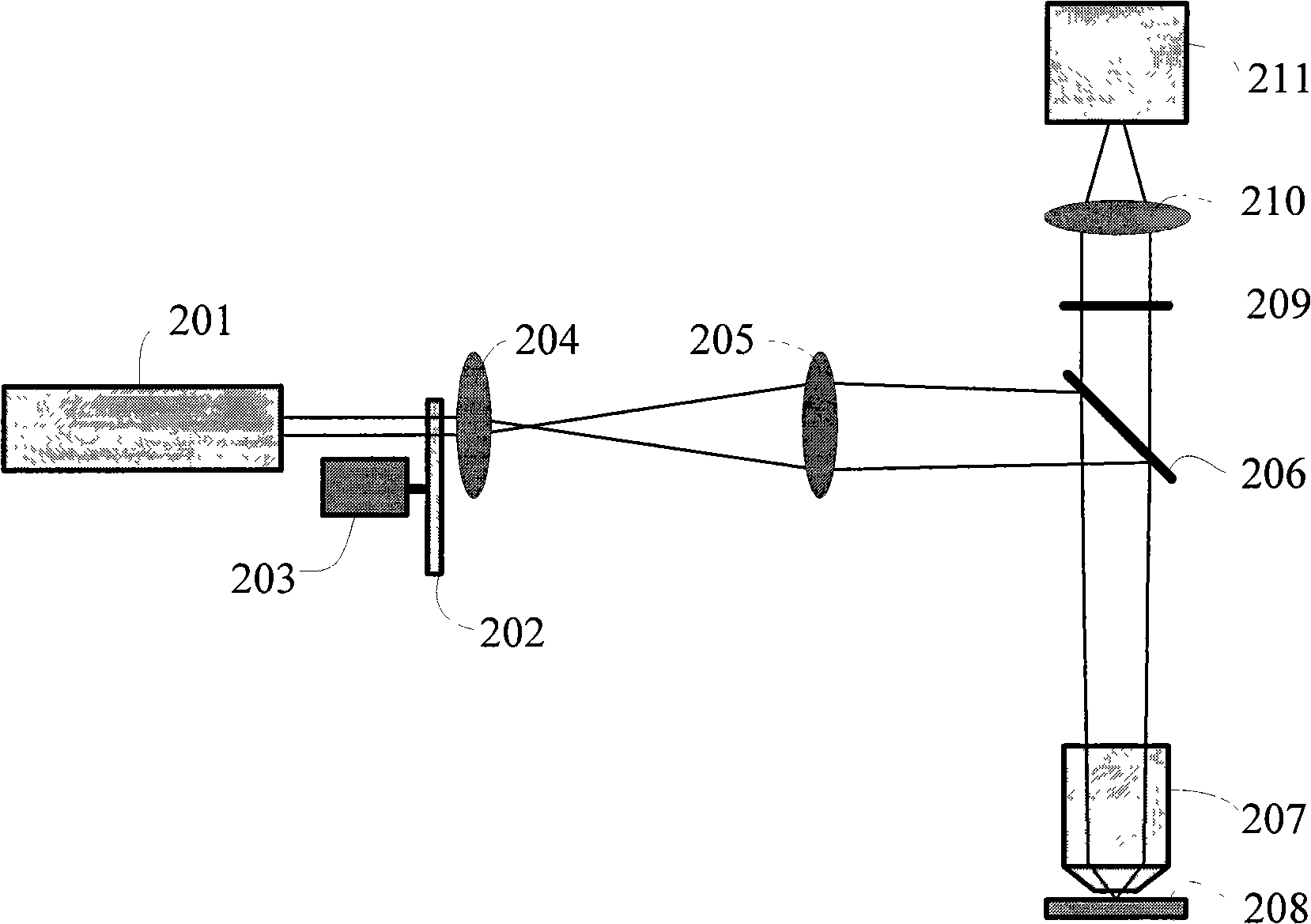

Method and apparatus realizing quasi confocal fluorescent microscopic with dynamic speckle illumination

InactiveCN101303302AGood value for moneySimple structureScattering properties measurementsFluorescence/phosphorescenceMicroscopic imageEffect light

The present invention relates to a novel method and a novel device, incorporating dynamic speckle lighting with a conventional wide field fluorescence microscope organically to implement approximately confocal fluorescence microscopy (i.e., quasi-confocal fluorescence microscopy). The present invention employs an argon ion laser as the light source; the exciting light passes through a scattering object, a relay light path system for expanding and shaping, and then is coupled to the fluorescence microscope and focused to the sample. The stepping and revolution of the scattering object is controlled with a computer to produce a dynamic speckle pattern on the sample. The received fluorescent images are processed to obtain high-resolution spatial chromatographic images under no need to scan condition. The method can be used to obtain high-resolution three-dimensional chromatographic and microscopic image information of biological tissue samples in a non-intrusive manner. The device has simple structure, high cost-performance ratio, and is favorable for post data processing, easy to operate and apply; therefore, the device and method have a wide market application prospect and great significance for clinical diagnosis and life science research.

Owner:SHENZHEN UNIV

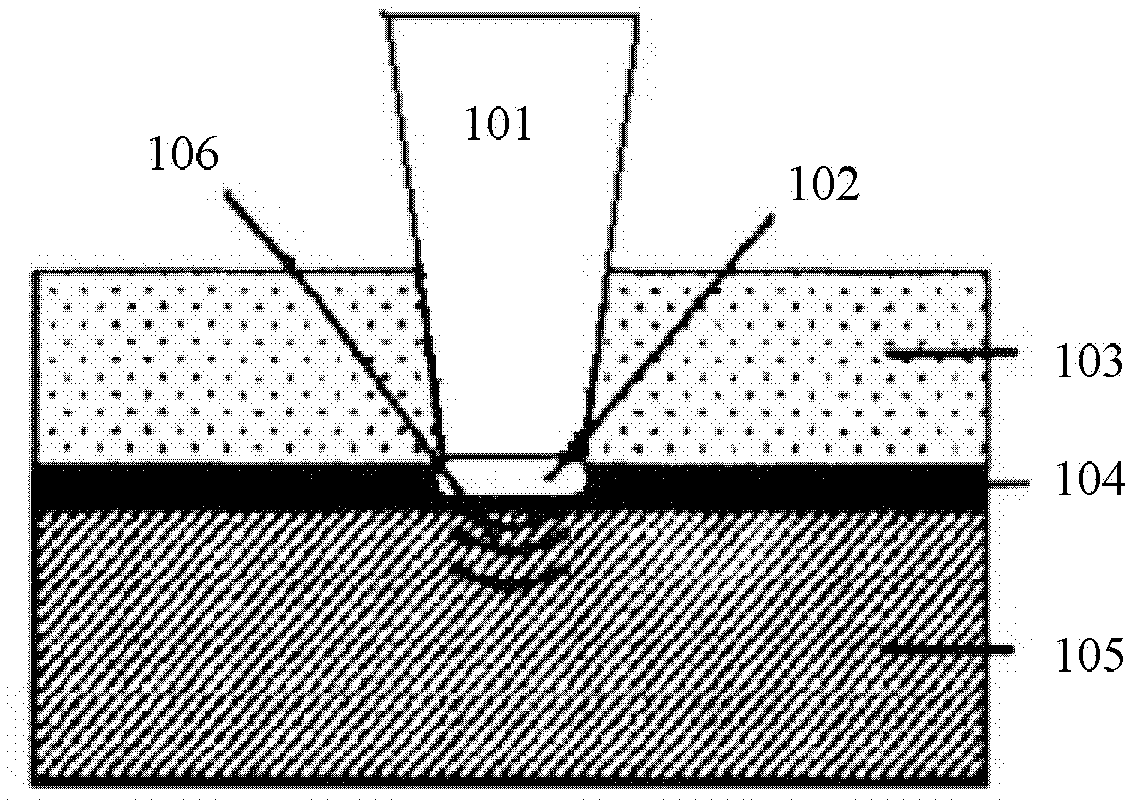

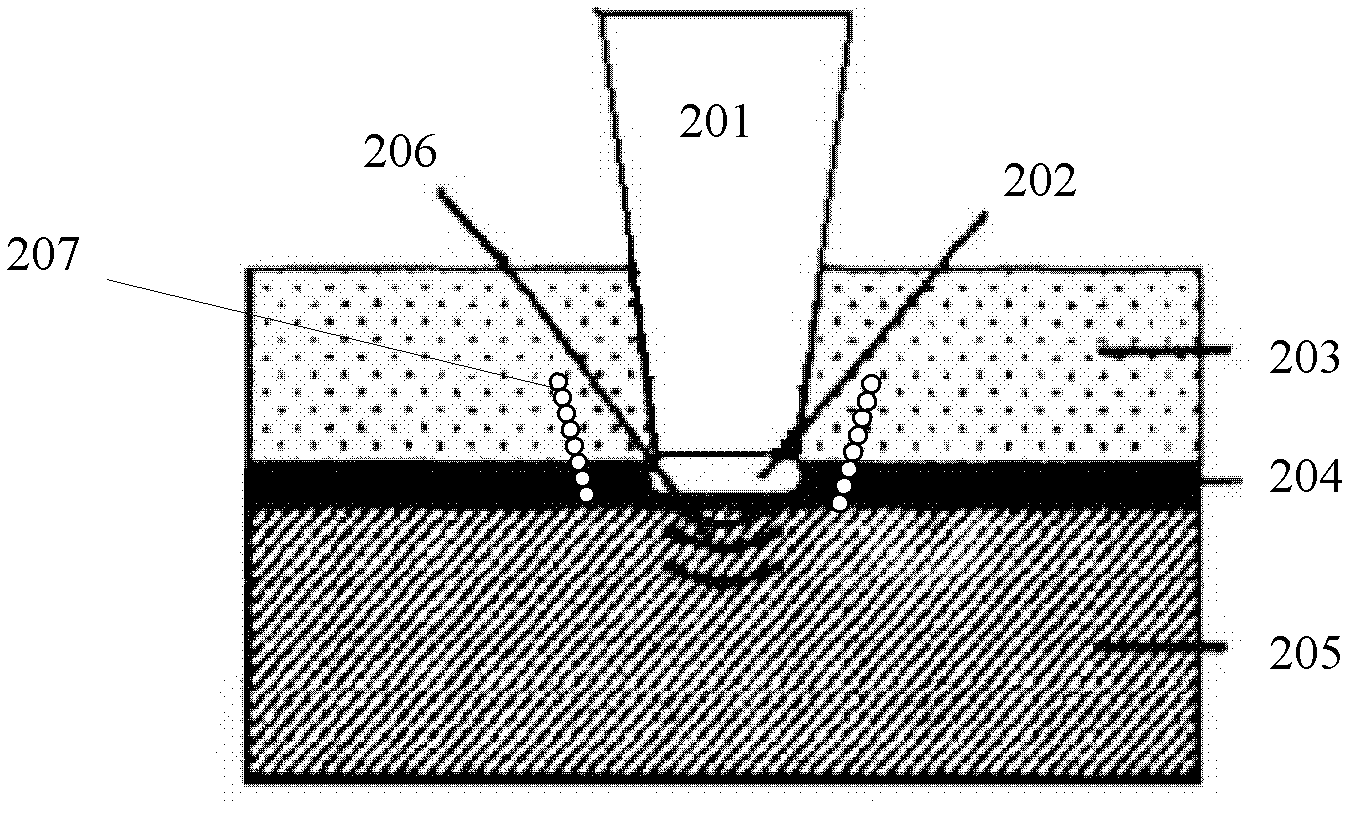

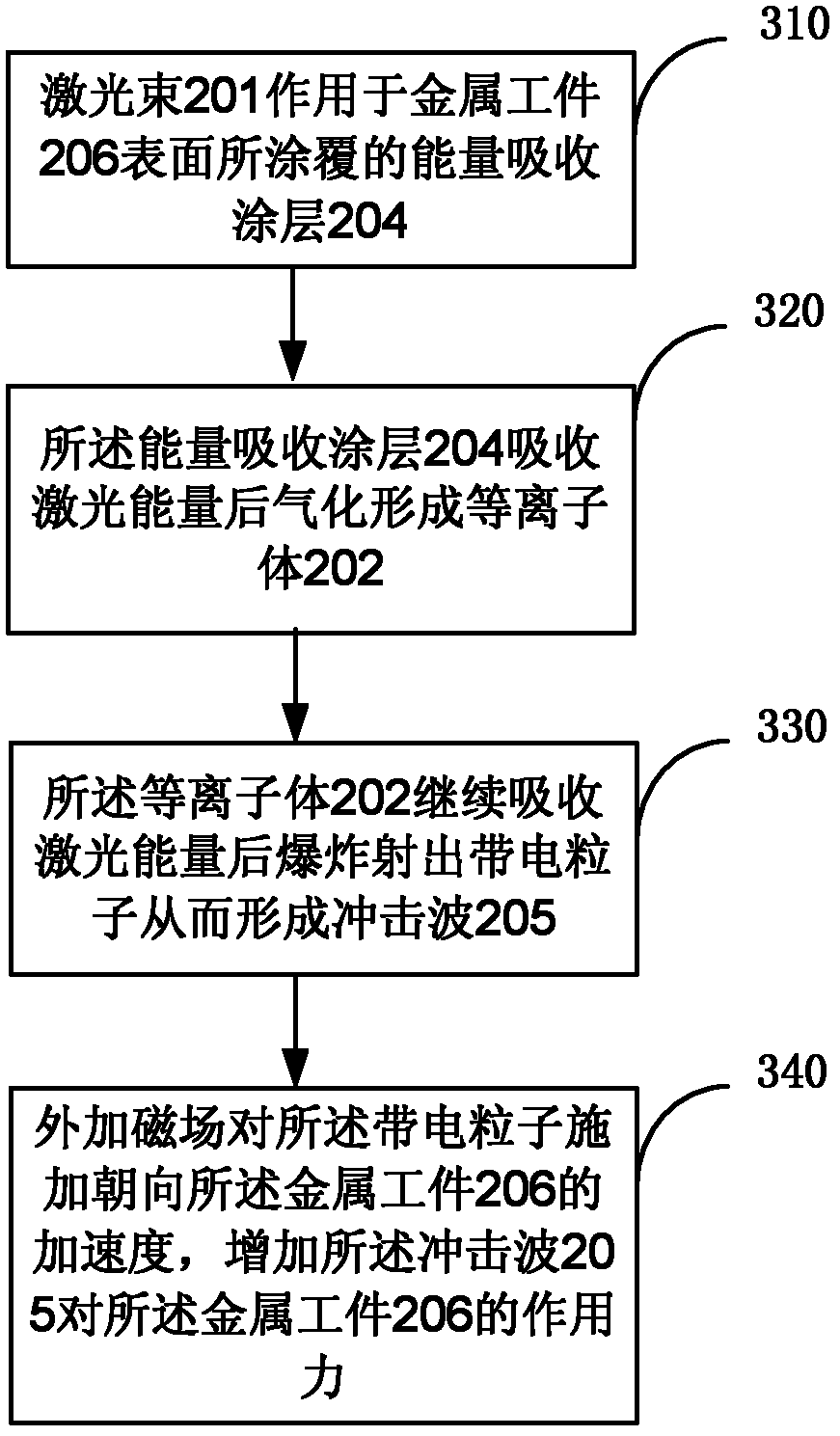

Laser shock method and laser shock device

InactiveCN102489877APrecise positioningWide applicabilityLaser beam welding apparatusShock waveEnergy absorption

The invention discloses a laser shock method and a laser shock device. The laser shock method comprises the following steps that: 1, a laser beam acts on an energy absorption coating coated on the surface of a metal workpiece; 2, the energy absorption coating absorbs laser energy and then is gasified to form a plasma; 3, the plasma continues to absorb the laser energy and then explodes to eject charged particles so as to form shock waves; and 4, an external magnetic field imposes the acceleration facing the metal workpiece on the charged particles so as to increase the action force of the shock waves on the metal workpiece. By the method and the device, the intensity of the shock waves can be increased so as to perform contactless constraint on the plasma, so that the shock effect is improved and the environmental pollution is avoided.

Owner:HENAN UNIV OF SCI & TECH

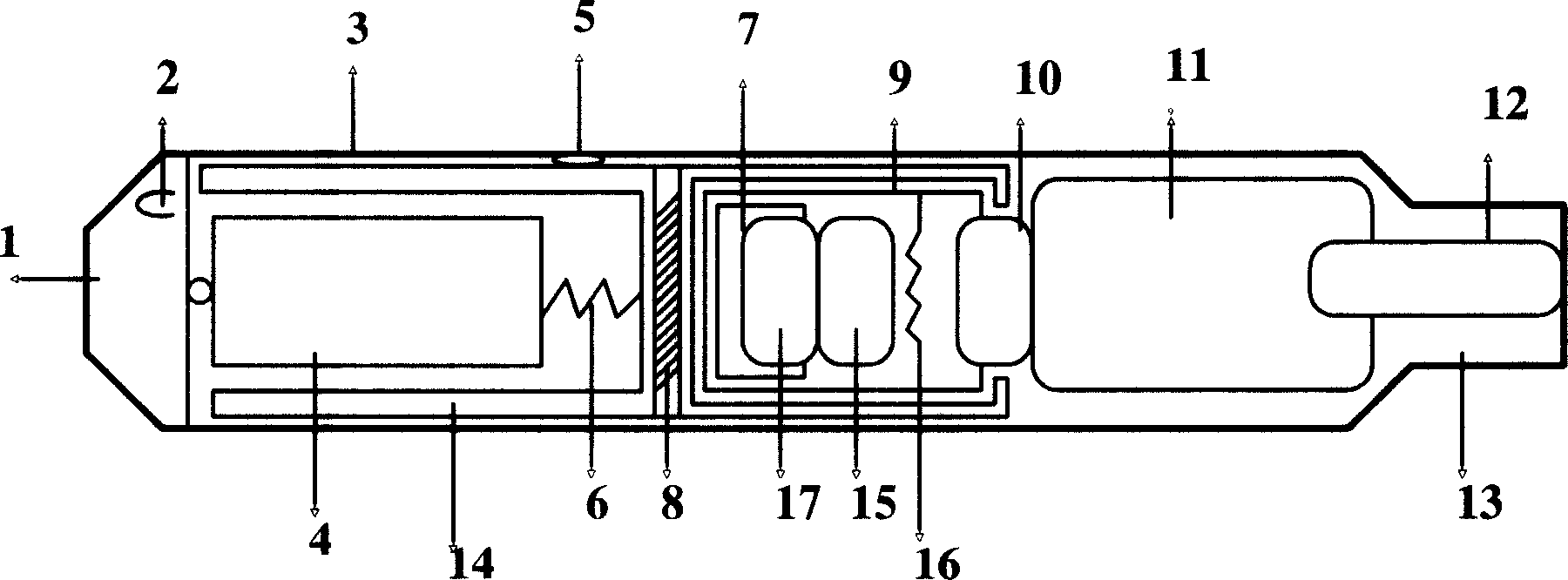

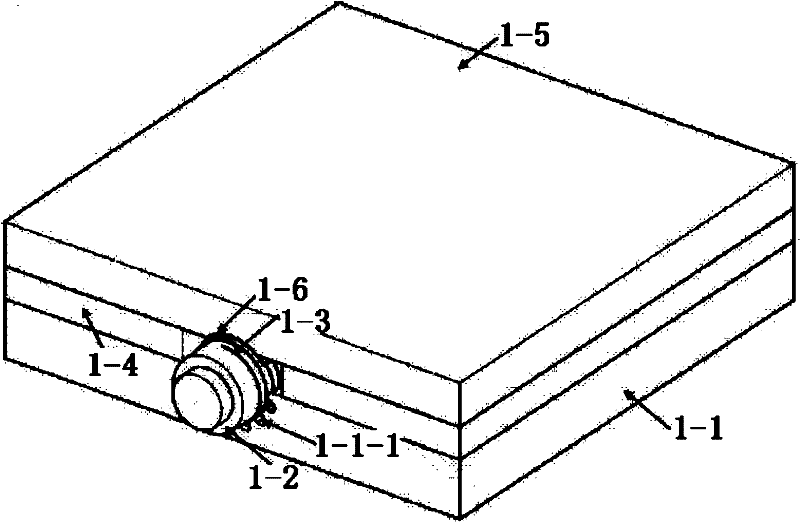

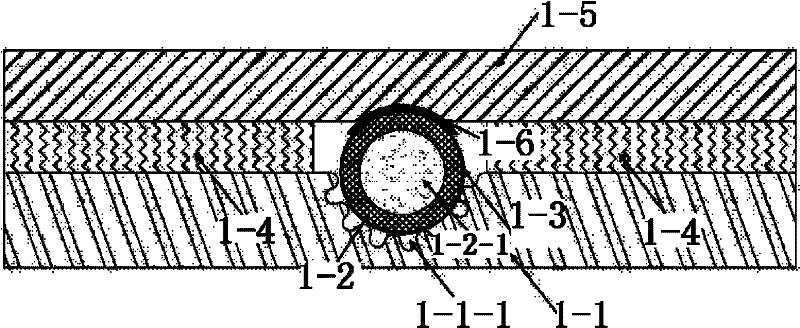

Portable atomized medicine introducing device

InactiveCN101053685AEasy to inhaleAvoid wastingAerosol deliveryMedical devicesEngineeringElectric control

The invention relates to a portable atomization administration apparatus, including a case having an air hole, an active separator arranged in the case dividing the case into to two chambers, wherein one chamber is provided with a liquor storage container with one end connected with an electric control pump connecting the atomization nozzle, and the other end is provided with a pressure sensor connected with the input end of the control circuit, while the other chamber of the liquor storage container is equipped with a cell connected with a diode. The device has small volume, light weight, low cost, and easy to carry along and realize the precise control, which can work along the breath rhythm of the human. The users inhale the medicine atomization air actively and spiritedly, wherein the atomization air is warm to enhance the thermal effect and can not cause the cough. The liquor is easy to be inhaled into the human body, and improves the therapeutic. The invention has simple structure, simple operation, which is applicable for the household and the personal and easy to popularize.

Owner:陈清甫 +1

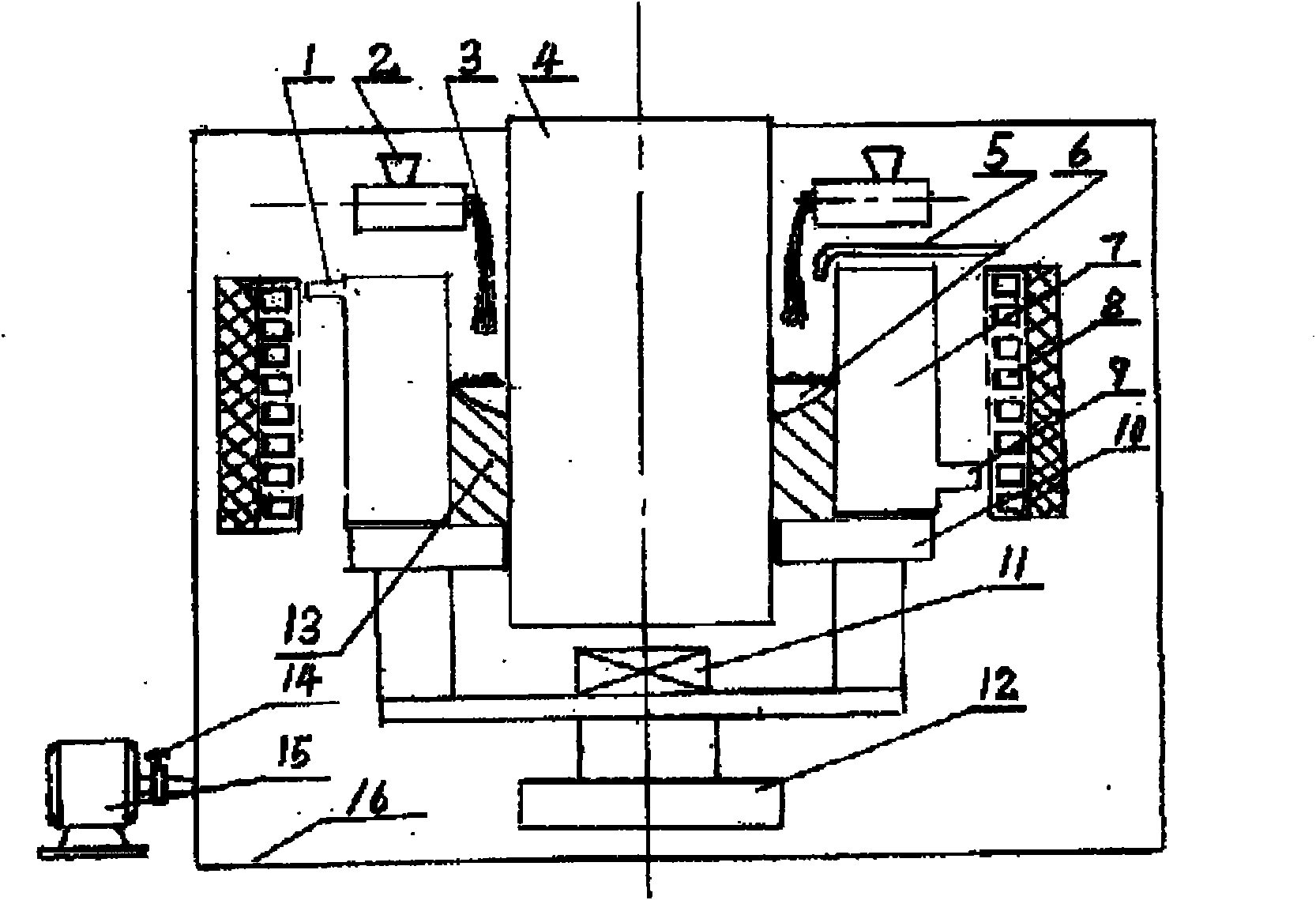

Micro-nano-alloy bimetal composite material preparation technique and device thereof

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

Stretched PVA (polyvinyl alcohol) film and preparation method for same

InactiveCN102604294AWiden the melting point distanceImprove water resistanceSynthetic resin layered productsPolymer scienceSwelling ratio

A stretched PVA (polyvinyl alcohol) film and a preparation method for the same belong to the field of high polymer packaging materials, and aim to solve the problems of high energy consumption, low production efficiency, complicated process and special equipment production during processing with water serving as solvent in the prior art. The stretched PVA film is of a monolayer structure or three-layer structure, wherein the monolayer structure refers to B, and the three-layer structure sequentially refers to A / B / A or B / A / B. The method includes the steps of melting plasticization, extrusion granulation, and uniaxial stretching or biaxial stretching so that the stretched PVA film is obtained. The stretching melting range of the stretched PVA film is from 160 DEG C to 240 DEG C. The stretched PVA film meets national standard of biological degradability, and the degradation ratio is larger than or equal to 70%. The stretched PVA film is high in water resistance, and the swelling ratio of the stretched PVA film soaking in water at the temperature of 23 DEG C for 48 hours is smaller than or equal to 120%.

Owner:朱春英

Mortgage option method

InactiveUS20050114259A1Stable and decreasing interest rateHuge marketFinanceSpecial data processing applicationsComputer scienceSelection method

The mortgage option method is a way that applicants wishing to take advantage of low mortgage interest rates, but who, for whatever reason, are unable or unwilling to initiate the application process at the present time, can obtain a right to the low mortgage rate at some time in the future when mortgage rates have increased. Designed for either the residential or commercial real estate market, method allows customers to lock-in a mortgage at the then current rate for up to four years by paying a nonrefundable up-front premium. The mortgage option may be exercised at any time during the option term, at a rate lower than the prevailing rates.

Owner:ALMEIDA JOE W

Nicotine-alternative compositions and methods of producing such compositions

InactiveUS20100160376A1Low production costImprove marketabilityBiocideNervous disorderNicotine replacementAlkaloid

A method for producing a consumable nicotine-alternative composition includes measuring a quantity of a cigarette nicotine-alternative alkaloid and / or a larger quantity of lobeline. The quantities of cigarette nicotine-alternative alkaloid and / or lobeline are diluted into one or more successive intermediate solutions, a last of which constitutes a final solution. The final solution is apportioned so that each portion contains a precise quantity of cigarette nicotine-alternative alkaloid and / or lobeline appropriate for consumption in a single use by a single person. Each portion is introduced into a separate single-serving dispenser.

Owner:THOMPSON MARSHALL ANLAUF

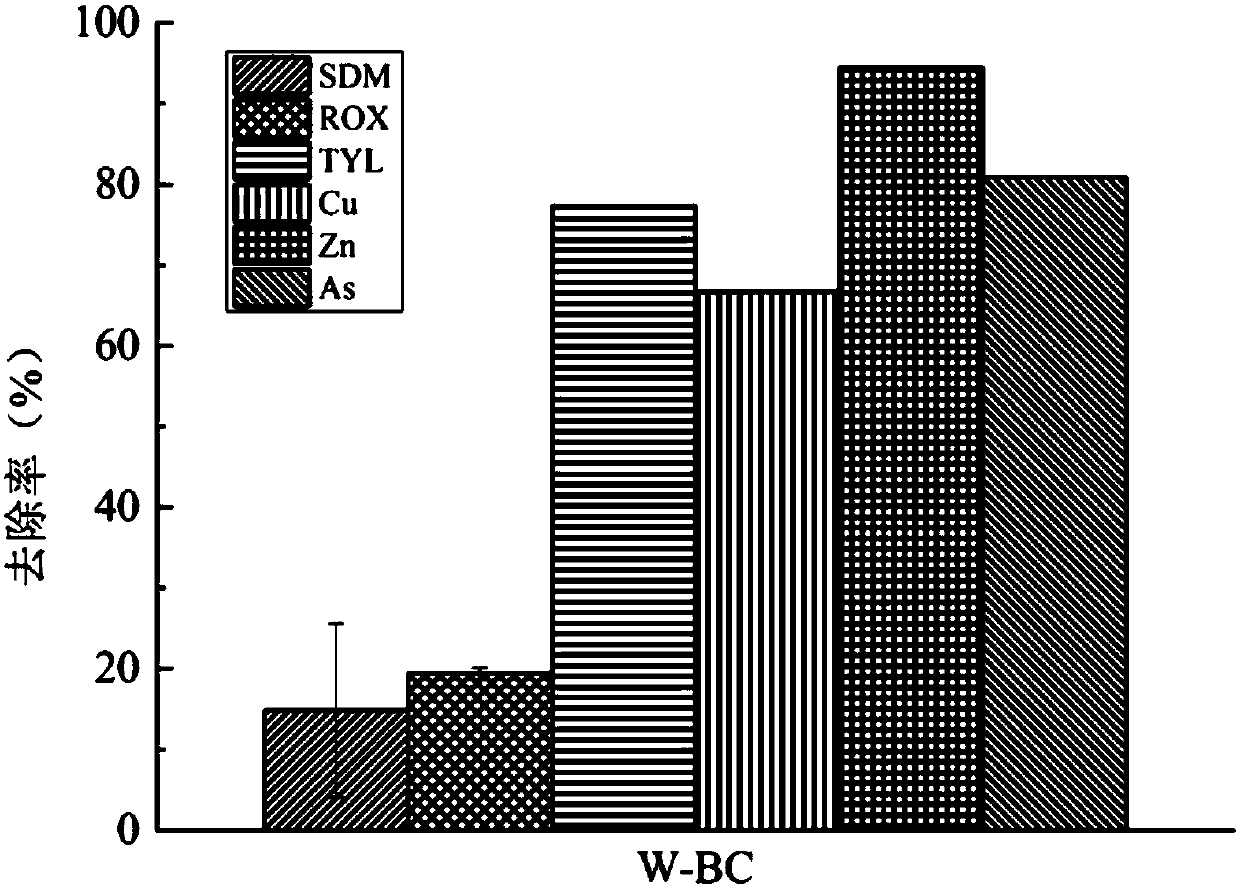

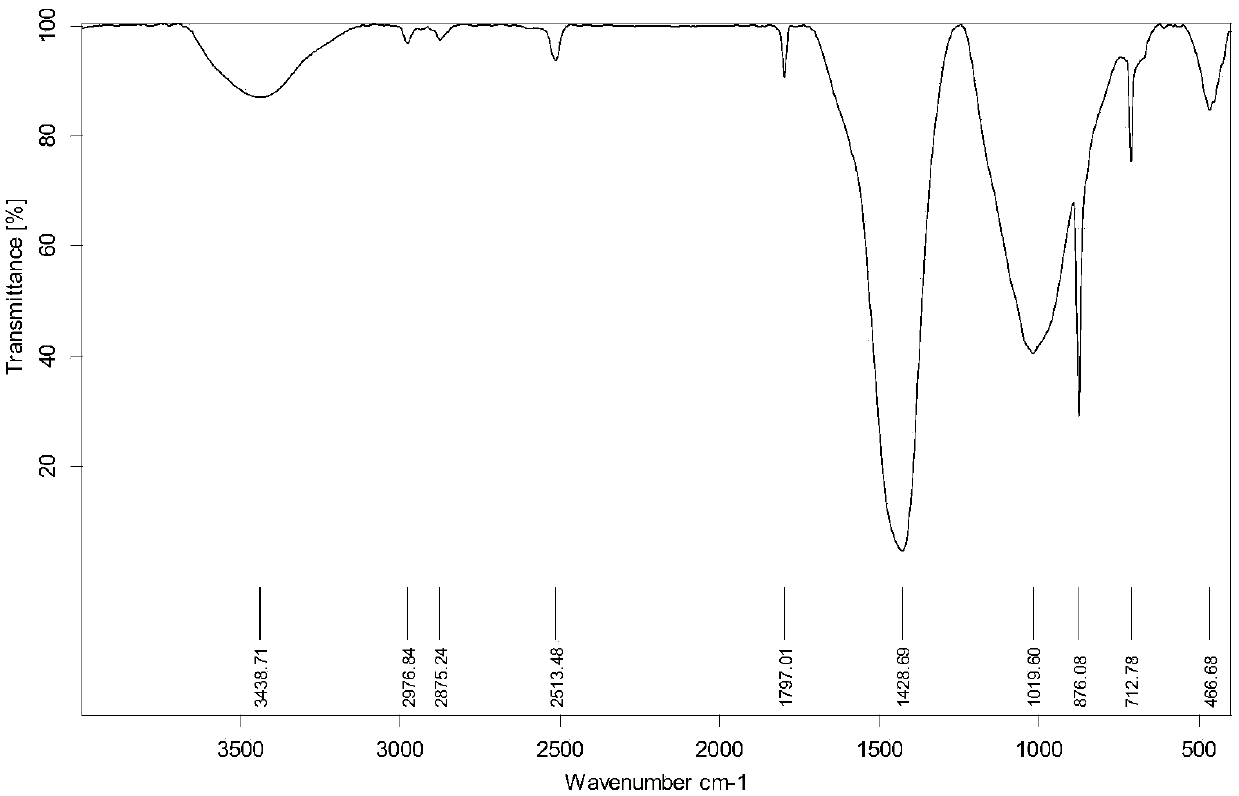

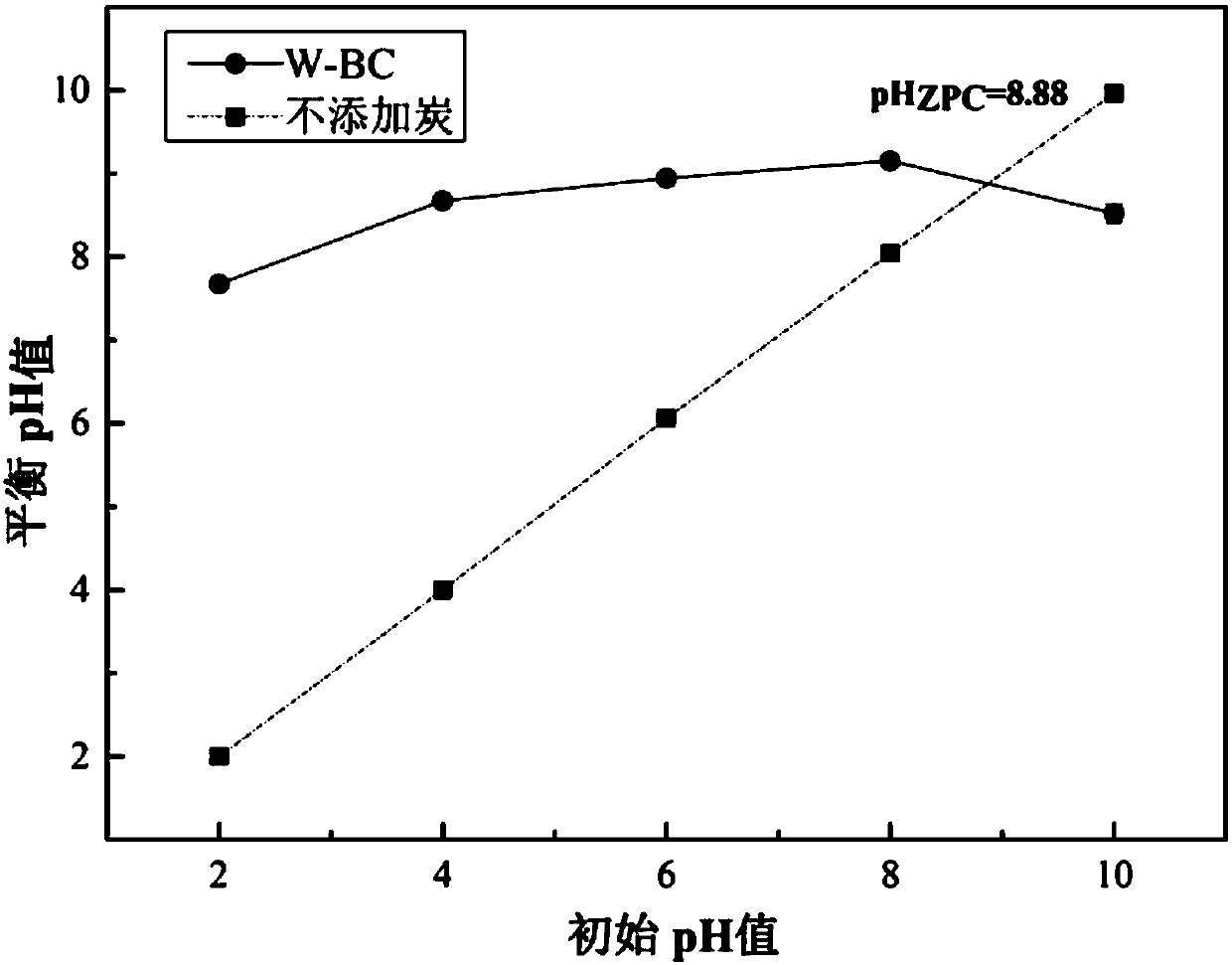

Application of papermaking sludge based biological carbon in removal of antibiotics or heavy metals and antibiotics from water body

InactiveCN107686142ASolve pollutionImportant environmental benefitsWater contaminantsWaste water treatment from animal husbandryRoxithromycinAntibiotic Y

The invention discloses application of papermaking sludge based biological carbon in removal of antibiotics or heavy metals and the antibiotics from a water body and belongs to the technical field ofbiomass treatment and water treatment. The papermaking sludge based biological carbon has larger specific area and a larger pore size and can efficiently remove combined pollution of copper, zinc, arsenic, sulfadimidine, tylosin and roxithromycin. The biological carbon is simple in preparation technology, significant and stable in effect, environment-friendly and free from secondary pollution, andhas a wide application value in a heavy metal / antibiotic pollution repair aspect in the water body. Paper mill sludge difficult to treat is recycled; the environmental pollution problems of wastewater containing the heavy metals and the antibiotics are solved; and therefore, the application has important environmental and economic benefits. The biological carbon has a huge market and an application potential in waste recycling and sewage treatment.

Owner:SOUTH CHINA AGRI UNIV

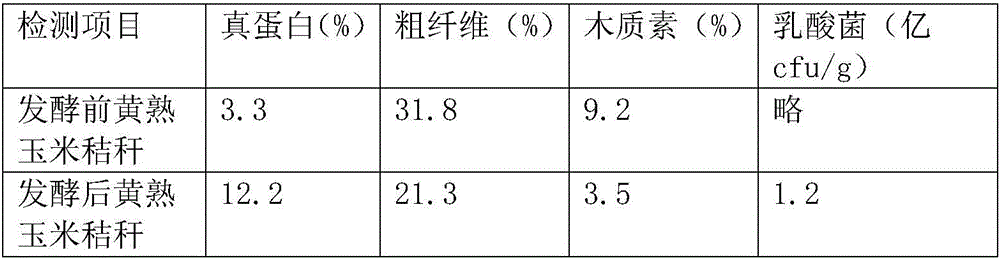

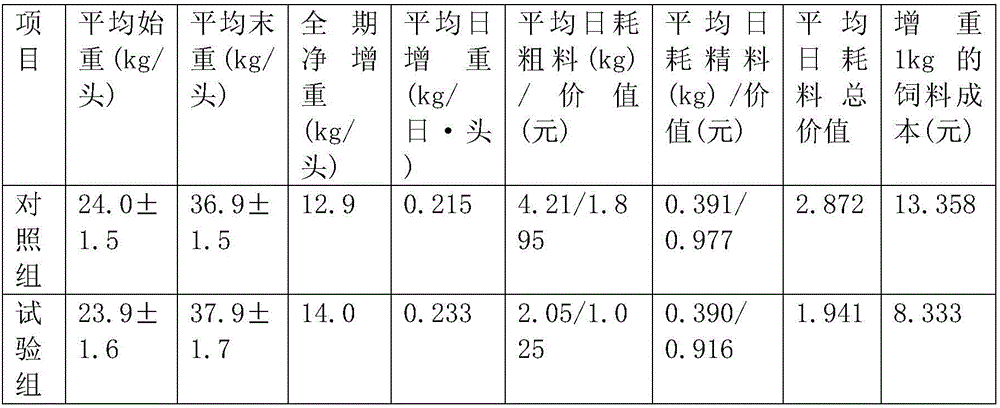

Integration processing method of high-efficient corn straw biological feed

InactiveCN105918614AIncrease profitImprove the environmentFood processingAnimal feeding stuffBiotechnologyFermentation

The invention discloses an integration processing method of a high-efficient corn straw biological feed, and belongs to the field of biological feeds. Corn straw is subjected to three-step fermentation, so that a superior microorganism coarse feed for ruminant animals, with high efficiency and low cost, is produced in a large-scale manner. The integration processing method comprises the following steps of firstly, based on the corn straw, performing high-efficient pure solid cultivation on a white rot fungus enzyme preparation, then converting the cultivated white rot fungus enzyme preparation in large inoculum amount to a first-stage fermentation medium of the corn straw, and besides, inoculating serial lignocelluloses degradation bacteria and candida utilis bacteria for synergistic rapid degradation and transformation; then adding bacillus and saccharomyces cerevisiae for second-stage fermentation; and using lactic acid bacteria for third-stage anaerobic fermentation so as to obtain finished products. The raw materials used by the integration processing method do not need to be sterilized, the finished products do not need to be dried, lysozymes are enriched, the cost is low, the lignin is notably reduced, and genuine protein is increased to 12% or above. The high-efficient corn straw biological feed can be used as a superior coarse feed and a protein grain feed for cattle and sheep, and the additive quantity can reach 60% or above; the additive quantity can also be about 10%, so that the high-efficient corn straw biological feed is used for simple stomach animals. The technique is high in scalability and integrity, and the economic and social benefits are notable.

Owner:陈华友

Preparation method of medium temperature ferric oxide desulfurizer

ActiveCN101590358ASimple processFew stepsDispersed particle separationCalcium hydroxideHigh volume manufacturing

The invention provides a preparation method of a medium temperature ferric oxide desulfurizer, and the active component of the medium temperature ferric oxide desulfurizer is amorphous ferric oxide of high activity. The preparation method of the medium temperature ferric oxide desulfurizer comprises the steps of directly kneading soluble ferrite, calcium hydroxide and a binder, extruding, drying and roasting. The desulfurizer obtained by using the preparation method of the invention has high content of ferric oxide, high sulphur capacity and good desulfurizing property; in addition, the preparation method of the invention has the advantages of simple process, low cost and suitability for industrialized mass production. The desulfurizer of the invention is mainly used for medium temperature desulfurization of hydrogen sulfide in chemical fertilizer industry synthesis gas.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Multiple alloy co-carburized and enclosed coating and application therefor

The invention relates to a multi-element alloy co-infiltrated and sealed coating, which is characterized in that the anti-corrosion coating is a multifunctional coating combined with an infiltrated coating and a coating. The first layer is multi-alloy co-infiltration layer and passivation layer. Co-infiltration alloys include alloys such as zinc, aluminum and rare earth lanthanum oxide, and the passivation layer is a film layer that does not contain Cr6+. The second layer of aluminum-zinc sheet and epoxy resin is used as the sealing layer. The first layer of permeation layer and passivation layer is 35-50 μm, and the second layer of coating is 10-12 μm. After combining, the neutral salt spray resistance time can reach more than 500h, the coating hardness reaches 9H, and the relative wear amount is less than 50%. The cost performance of the coating provided is much better than that of the previous SDD-1 coating, and it has been successfully applied to the commonly used span beams of the non-chamber track of the passenger dedicated line with a speed of 350 km / h and the embedded steel plate and sleeve on the top of the railway bridge support.

Owner:SHANGHAI DACROMET SURFACE TREATMENT

Neuter breed cultivation method for fibraurea recisa pierre

InactiveCN101156527AReduce sizeImprove flatnessFertilising methodsCultivating equipmentsTwigPlant breeding

The invention provides an asexual propagation cultivating method for rhubarb vine, and relates to a plant breeding method, in particular to a medicinal plant breeding and cultivating method. The invention uses a twig of the rhubarb vine for cuttage and seedling, and the breeding method is as follows: A. the selection of a cuttage bed; B. the tidying up of the cuttage bed; C. the collection of the cuttage tress; D. the disinfection process of the tress; E. the cottage and management; F. the selection and the tidying up of the planting filed and the growth environment; G. the transplant and the management of the water and the fertilizer; I. to the arranging the rattan for climbing the frame; J. the prevention and cure of the pest. The actualization of the invention can improve the artificial breeding rate of the rhubarb vine, shorten the breeding period, avoid the excess pick of the wild rhubarb vine, protect the resource of the rhubarb vine, realize the industrialization planting of the rhubarb vine, facilitate the development and utilization of the rhubarb vine, provide process material to the pharmacy corporation for bright-marketing product, protect the wild resource, and preserve the water and oil.

Owner:屏边苗族自治县生物资源开发创新办公室

Kitchen residual garbage normal temperature anaerobic fermentation method

InactiveCN101063152AIncrease temperatureImprove thermal efficiencyFermentationSocial benefitsHydrogen

The invention discloses a method to proceed normal temperature anaerobic fermentation with kitchen garbage, which comprises the following steps: mixing the kitchen garbage and water with a finite proportion; grinding to proper grain size with food breaker; sieving; sieving the surplus sludge; mixing with the grinding garbage with a finite proportion; proceeding heat treatment; getting mixture; using as joint ferment base material; placing in closed fermenter; proceeding anaerobic fermentation at room temperature; generating hydrogen; proceeding simple pretreatment; using as fuel or generating raw material. This invention possesses better economic benefit, social benefit and environmental benefit.

Owner:DONGGUAN KECHUANG FUTURE ENERGY SOURCE TECHDEV

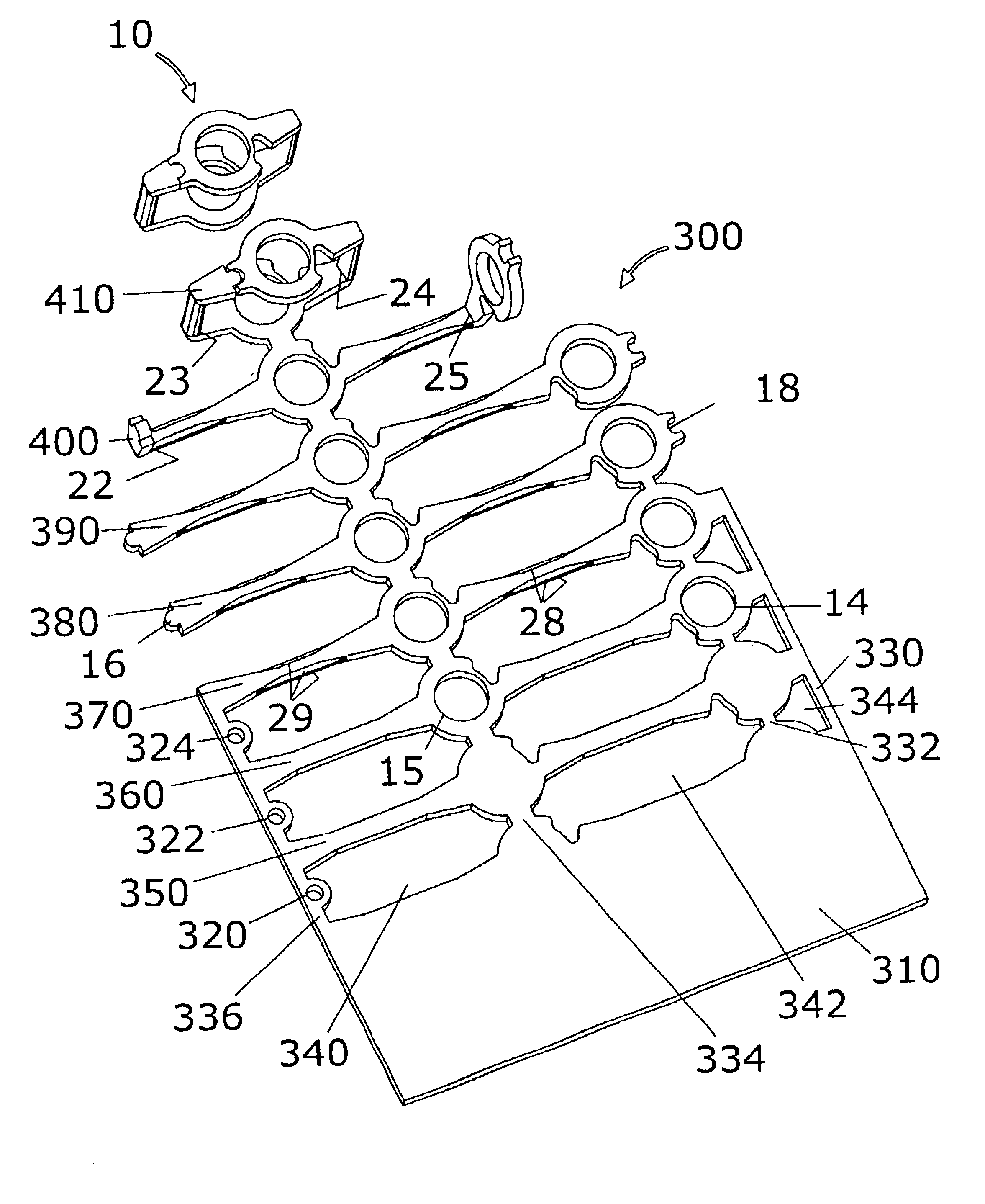

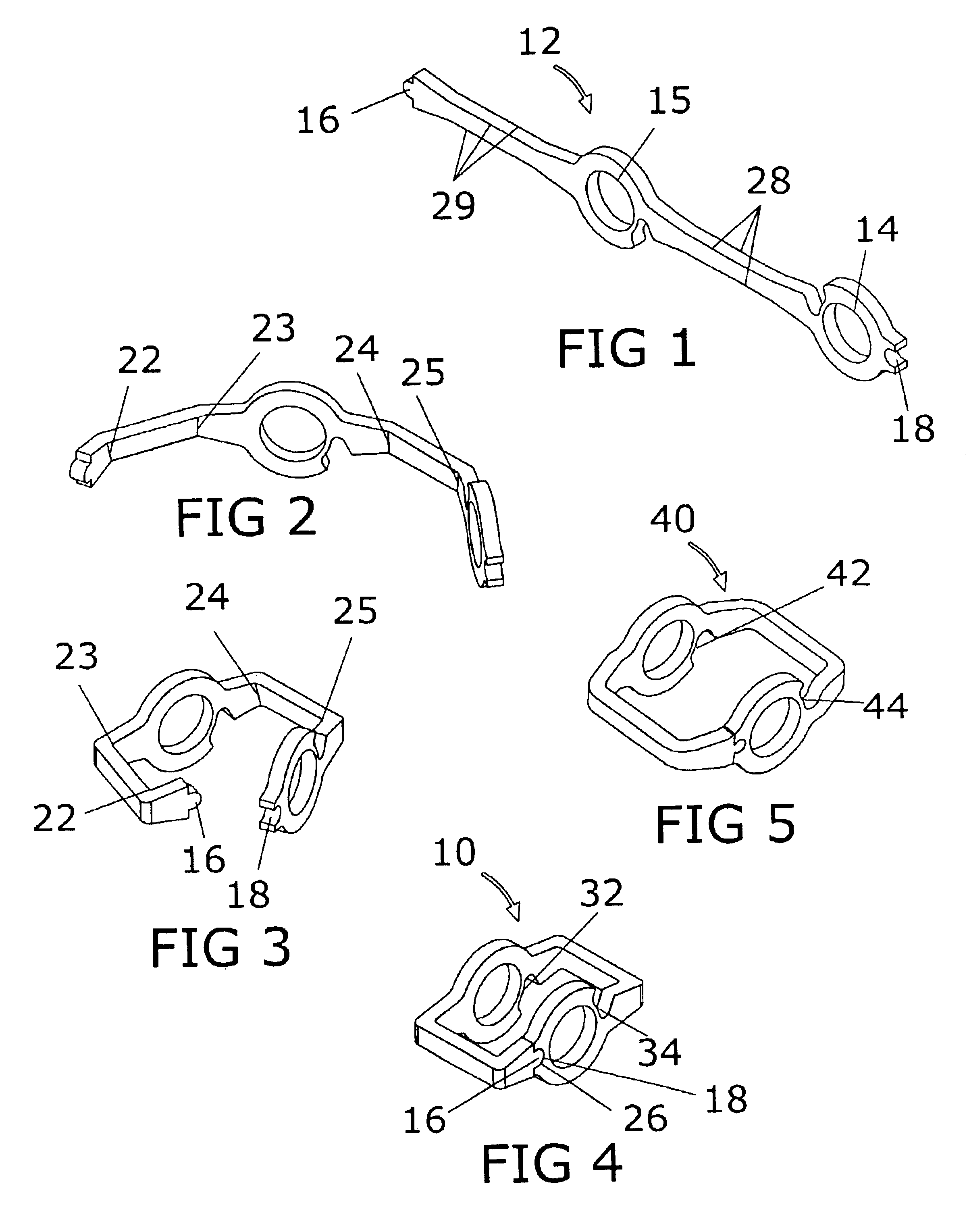

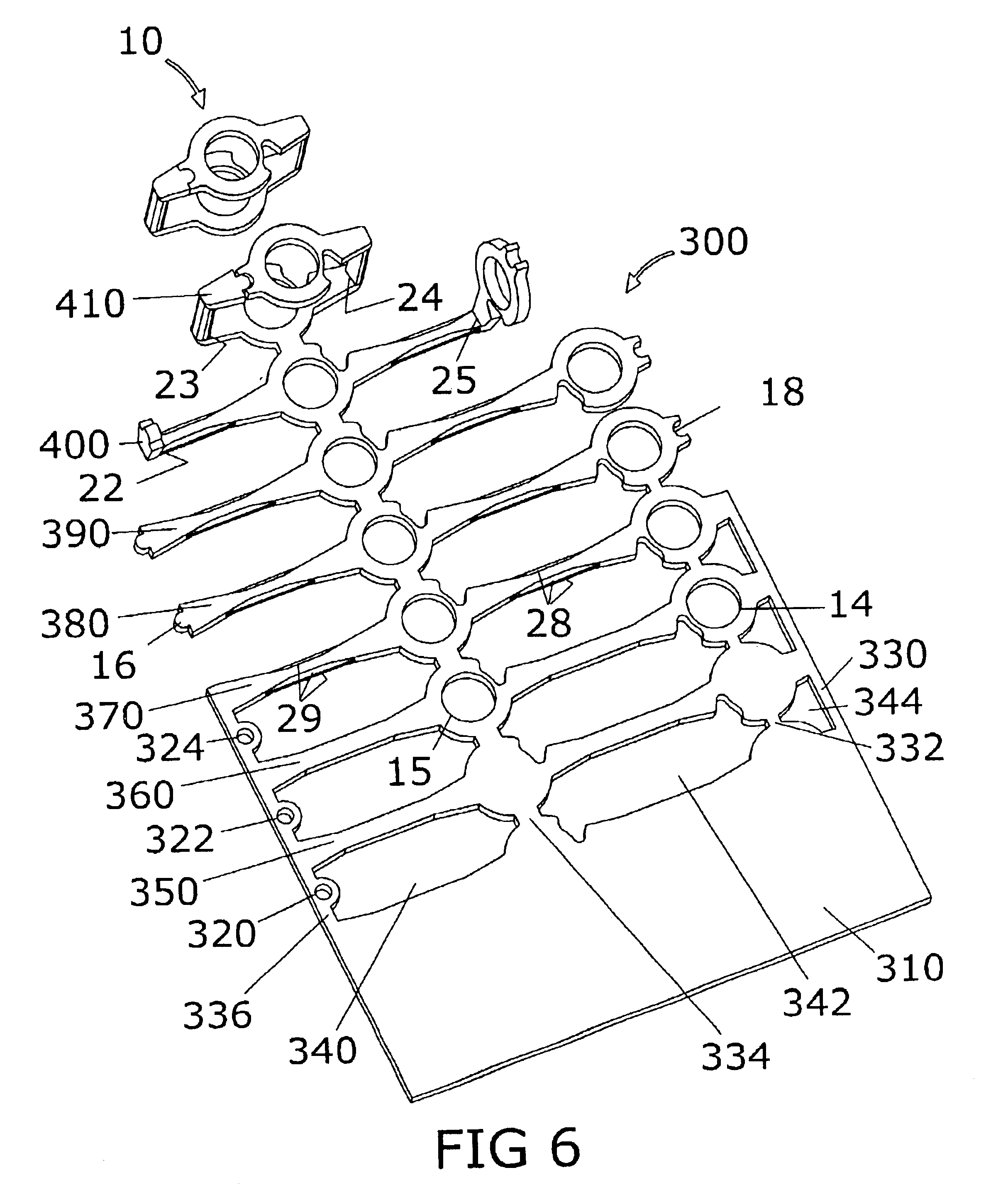

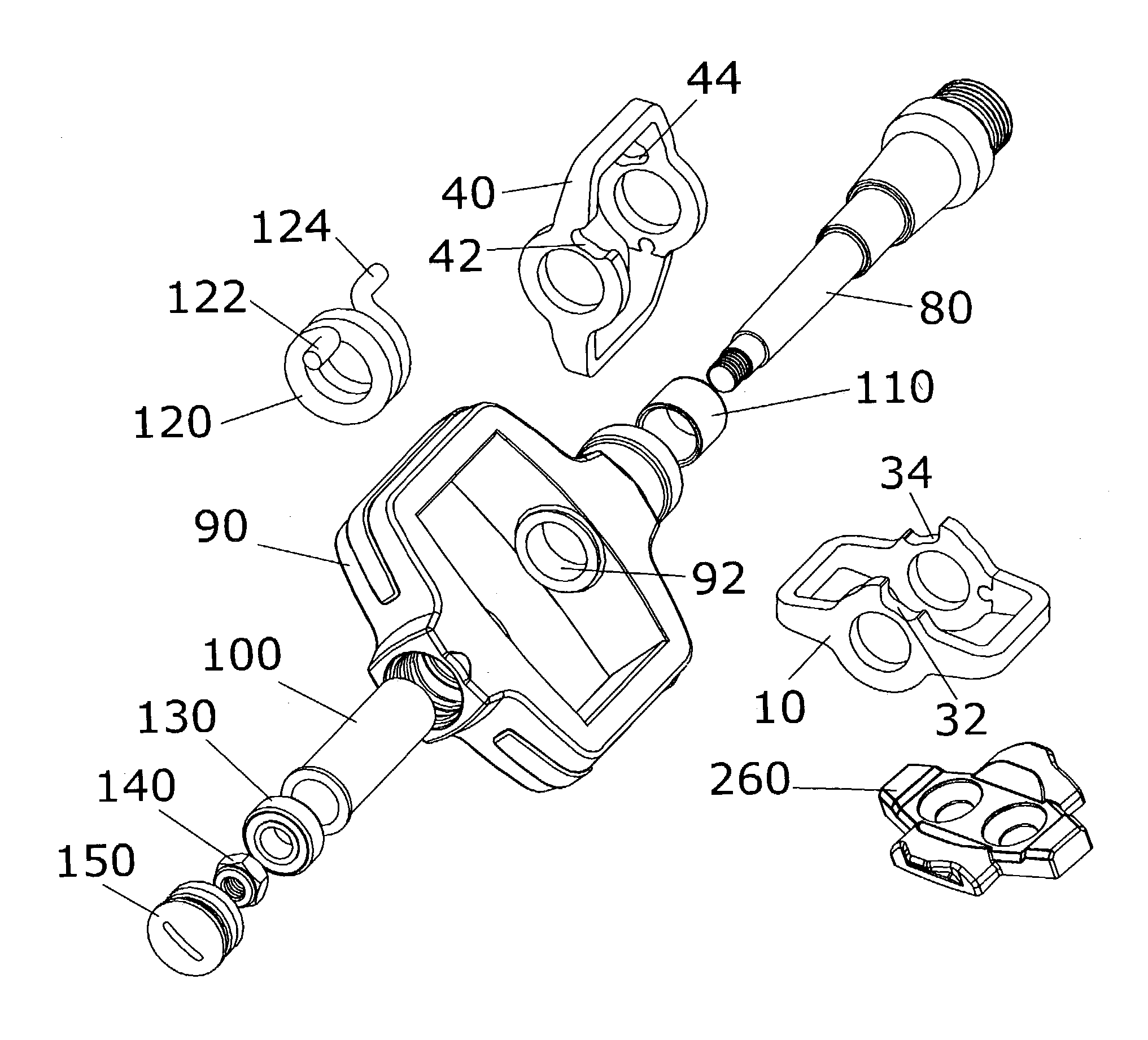

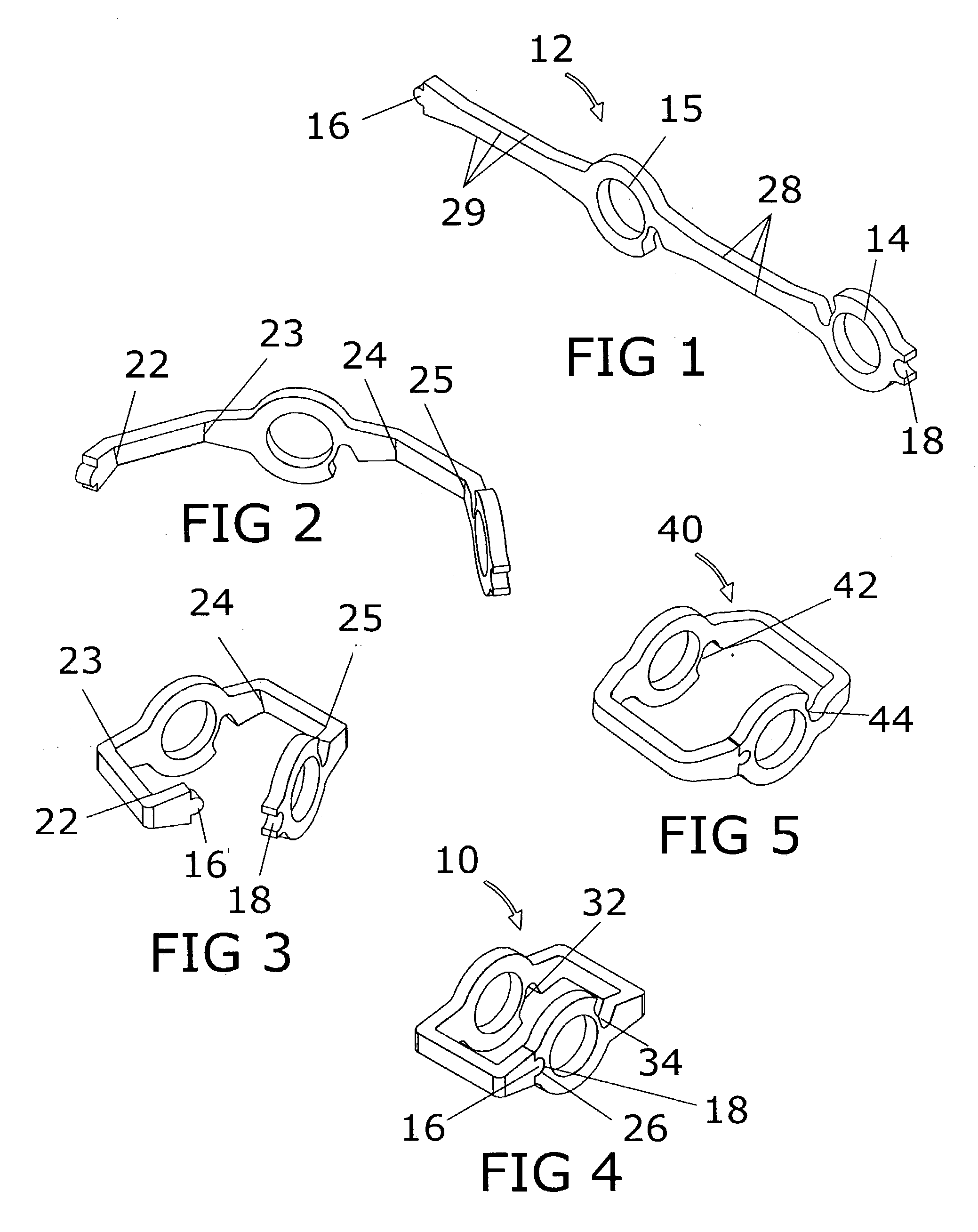

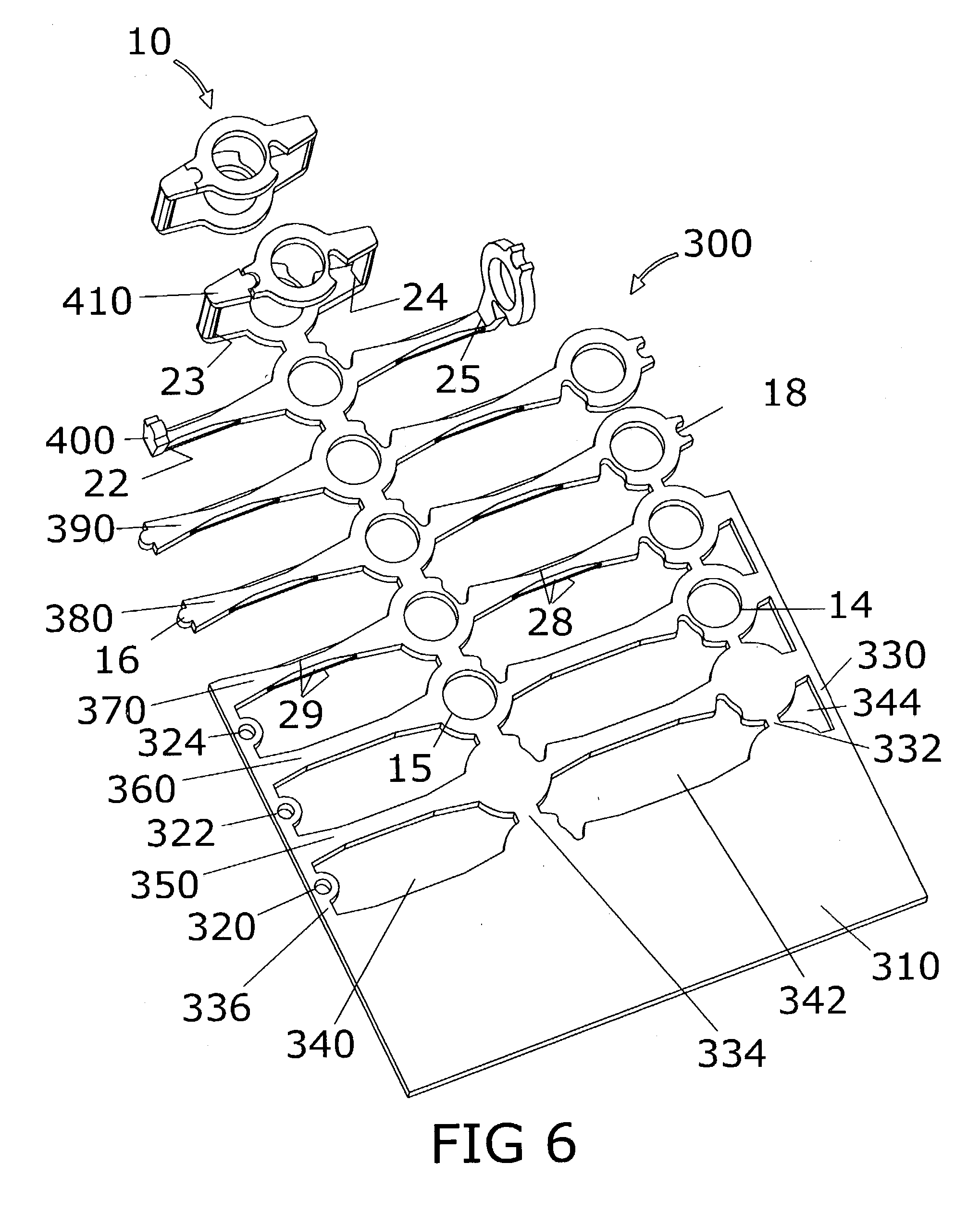

Method of fabricating a clipless bicycle pedal

A clipless mechanism for a four-sided clipless bicycle pedal is made by a stamping and welding process. The stamping is preferably a progressive stamping process. The stamped parts include two components, an inner wing and an outer wing. The two stamped components are generally similar in shape to each other, but the inner wing fits within the outer wing. Each part is first stamped as a flat pattern by a progressive die. Each part then has radii stamped into the edges by the second station of the progressive die. Next, each part is partially folded by the third station of the progressive die. Then each part is folded completely by the fourth station of the progressive die. The actual number of steps may vary depending upon the material chosen, the thickness of the material and the design of the stamping tool. Then each part is welded closed and the resulting rectangular wings are assemblied in juxtaposed orthogonal relation to provide four shoe cleat engaging receptacles.

Owner:CRANK BROS INC

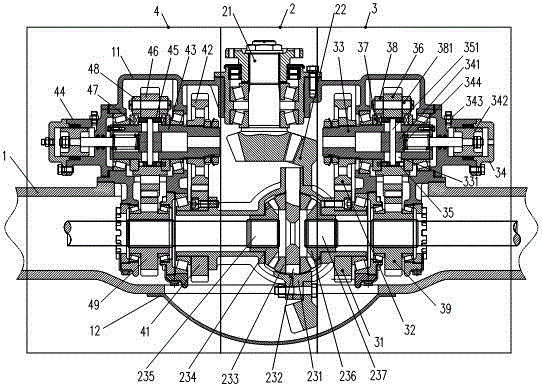

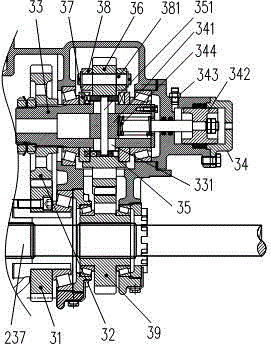

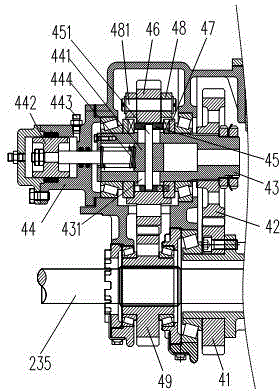

Self-adapted traction control drive axle differential mechanism

The invention relates to a self-adapted traction control drive axle differential mechanism. The differential mechanism is composed of a main reduction differential mechanism, a right drive torsion adjusting device and a left drive torsion adjusting device, wherein the right drive torsion adjusting device and the left drive torsion adjusting device are symmetrically arranged, are fixed on a differential mechanism shell of the main reduction differential mechanism, and have the same structure and same acting performance; and each of the right drive torsion adjusting device and the left driven torsion adjusting device comprises a torsion adjusting driving gear, a torsion adjusting driven gear, a hollow shaft, an air cylinder and a clutching mechanism. The differential mechanism has no inner speed difference interference, has high driving efficiency and saves fuel oil; torques needed by attaching conditions of all wheels can be automatically adjusted to drive an automobile to move, and the driving force of each wheel can reach the optimal state; The fundamental difference between the differential mechanism provided by the invention and an existing regular locking differential mechanism is that a bidirectional clutch is arranged and is normally engaged to control the torsion performance; and the differential mechanism is pneumatically reversed in a process of baking up. Therefore, the power utilization rate and the all-terrain and all-weather working conditions are greatly improved, and the self-adapted control capability can be 100% so that the differential mechanism can be used for large and small vehicles.

Owner:十堰戎马汽车特种传动有限公司

Antiseptics for natural food

An antiseptic agent for food (white gourd, aubergine, tomato, meat, egg, etc) is prepared from the extract of balsam pear and / or extract (or allicin) of garlic clove, and amino acid type polypeptide through proportional mixing, washing with solvent for deodoring and sterilizing.

Owner:袁东武

Method of fabricating a cliples bicycle pedal

InactiveUS20040168542A1Short timeA large amountControlling membersMechanical apparatusSlide plateEngineering

A clipless mechanism for a four-sided clipless bicycle pedal is made by a stamping and welding process. The stamping is preferably a progressive stamping process. The stamped parts include two components, an inner wing and an outer wing. The two stamped components are generally similar in shape to each other, but the inner wing fits within the outer wing. Each part is first stamped as a flat pattern by a progressive die. Each part then has radii stamped into the edges by the second station of the progressive die. Next, each part is partially folded by the third station of the progressive die. Then each part is folded completely by the fourth station of the progressive die. The actual number of steps may vary depending upon the material chosen, the thickness of the material and the design of the stamping tool. Then each part is welded closed and the resulting rectangular wings are assemblied in juxtaposed orthogonal relation to provide four shoe cleat engaging receptacles.

Owner:CRANK BROS INC

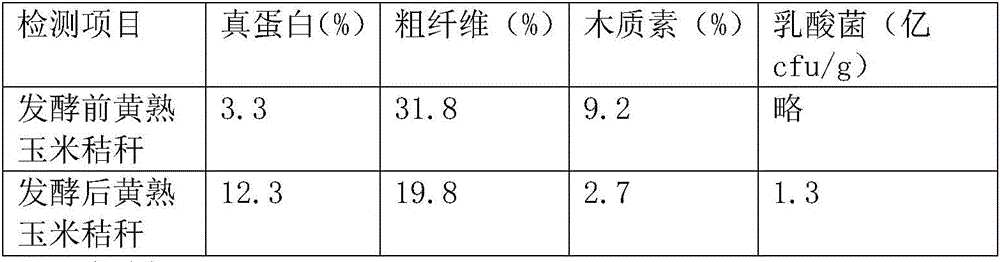

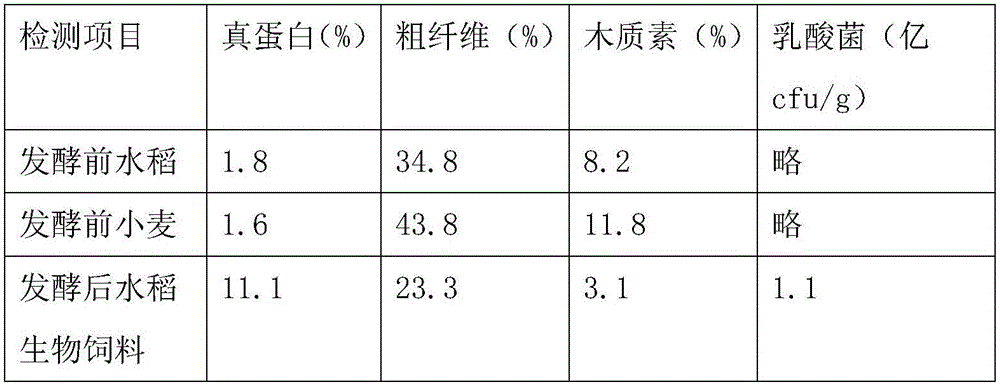

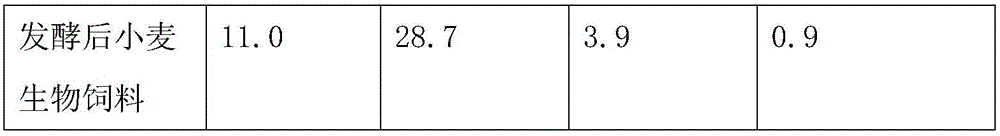

Production method of large-scale rice wheat straw microorganism feed

ActiveCN105918615AIncrease profitHigh technology integrationFood processingAnimal feeding stuffBiotechnologyMicroorganism

The invention discloses a production method of a large-scale rice wheat straw microorganism feed, and belongs to the field of biological feeds. Rice wheat straw is used as a main carbon source, and inorganic nitrogen is used as a main nitrogen source. The production method comprises the following steps of performing high-efficient pure solid cultivation on a white rot fungus enzyme preparation, then converting the cultivated white rot fungus enzyme preparation in large inoculum amount to a first-stage fermentation medium of the rice wheat straw, and besides, inoculating serial lignocelluloses degradation bacteria and candida utilis bacteria for synergistic rapid degradation and transformation; adding bacillus and saccharomyces cerevisiae for second-stage fermentation; and using lactic acid bacteria for third-stage anaerobic fermentation so as to obtain finished products. The lignin of the straw biological feed is greatly reduced, genuine protein is increased to 11%b or above, and the raw materials do not need to be sterilized; the finished products do not need drying treatment, lysozymes are enriched, and the production cost is extremely low. The large-scale rice wheat straw microorganism feed can be used as a superior coarse feed and a protein grain feed for cattle and sheep, and the additive quantity can reach 60% or above; the additive quantity can also be about 10%, so that the large-scale rice wheat straw microorganism feed is used for simple stomach animals. The large-scale rice wheat straw microorganism feed is suitable for mass production, and the feeding and economic effects are obvious.

Owner:JIANGSU UNIV

Vehicle dynamic weighing sensor

InactiveCN102252740AIncreased durabilityReduce weightWeighing apparatus using elastically-deformable membersSpecial purpose weighing apparatusVehicle dynamicsGrating

The invention discloses a vehicle dynamic weighing sensor. The vehicle dynamic weighing sensor comprises an optical fiber microbend-elastic oil pipe sensor, an optical fiber raster-hydraulic sensor, first transmission optical fiber, second transmission optical fiber, third transmission optical fiber, fourth transmission optical fiber, a light intensity demodulation module, an optical wavelength demodulation module and a restrictor valve, wherein laser emitted by the light intensity demodulation module is introduced from the first transmission optical fiber to the optical fiber microbend-elastic oil pipe sensor and then is led out by the second transmission optical fiber to the light intensity demodulation module; laser emitted by the optical wavelength demodulation module is introduced from the third transmission optical fiber to the optical fiber raster-hydraulic sensor and then is led out by the fourth transmission optical fiber to the optical wavelength demodulation module; at least one overflow hole is formed in the restrictor valve; and the optical fiber microbend-elastic oil pipe sensor is communicated with the optical fiber raster-hydraulic sensor through the restrictor valve. The vehicle dynamic weighing sensor has high anti-electromagnetic interference capacity, measurement accuracy and high durability, is convenient to carry and realizes remote monitoring easily.

Owner:SOUTHEAST UNIV

Complex alloy co-carburized and enclosed coating and application therefor

The invention discloses a polyvalent alloy co-permeating closed coating, which is characterized by the following: the erosion-proof coating is composed of permeating and coating layer, which forms multi-functional layer; the first layer is polyvalent alloy co-permeating layer and inactivating layer; the zinc, aluminium and rare earth Lan are doped in the co-permeating alloy; the inactivating layer doesn't contain Cr6+; the second aluminium zinc piece and epoxide resin constitutes closed layer; the thickness of first permeating layer and inactivating layer is 35-50um; the thickness of second coating layer is 10-12um.

Owner:SHANGHAI DACROMET SURFACE TREATMENT

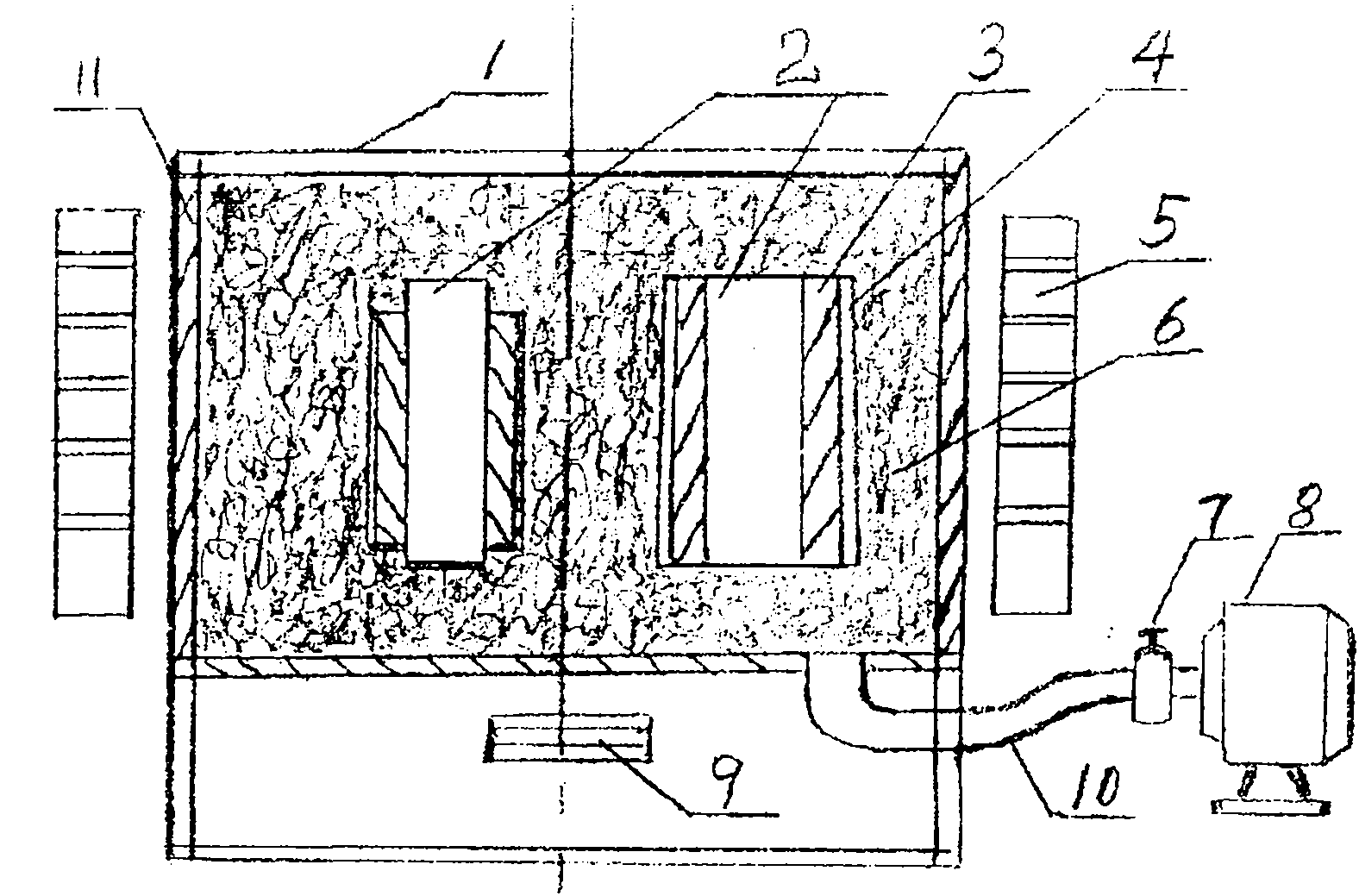

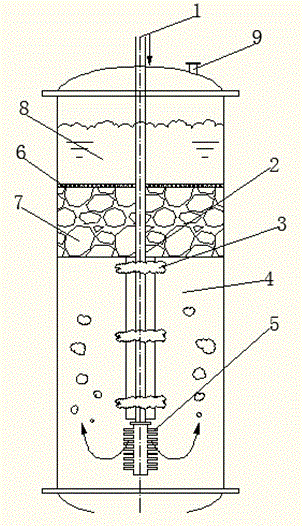

Gas-lifting type two-phase partition membrane bioreactor

ActiveCN105536512AReduce energy consumptionHigh trafficDispersed particle separationAir quality improvementMembrane bioreactorBiological membrane

The invention provides a gas-lifting type two-phase partition membrane bioreactor and belongs to the technical field of industrial organic waste gas purification. The bioreactor comprises a shell, a gas inlet and an exhaust funnel; the bioreactor is characterized in that the gas inlet is formed in the center of the upper end of the shell, and the exhaust funnel is arranged at the upper end of the shell; the shell is internally provided with a tail gas area, a microorganism reaction area and an aqueous phase area in sequence from top to bottom, the exhaust funnel is communicated with the tail gas area, and a biological membrane is arranged between the microorganism reaction area and the tail gas area; the shell is further internally provided with a gas pipe, the gas pipe is arranged at the central axis of the shell and sequentially penetrates through the tail gas area, the biological membrane and the microorganism reaction area, the upper end of the gas pipe is communicated with the gas inlet, and the lower end of the gas pipe is located at the bottom of the aqueous phase area. The bioreactor combines characteristics of the two-phase partition biotechnology and characteristics of the membrane biotechnology, is compact, simple, novel in structure and high in innovation, has the advantages of being thorough in destruction, free of secondary pollution, comparatively simple in procedure and the like and is an ideal organic waste gas purification means.

Owner:YANGZHOU UNIV

Formation method for improving capacity consistency of a waste hard-shell power lithium battery

ActiveCN107039699AImprove volume consistencyHigh activitySecondary cells charging/dischargingWaste accumulators reclaimingSurface layerInternal resistance

The invention relates to a formation method for improving capacity consistency of a waste hard-shell power lithium battery. The formation method comprises the steps of screening the battery, performing formation on the capacity consistency of a single battery, and finally, measuring and recording capacity, voltage and internal resistance performance of the single battery for use. By the formation method for improving the capacity consistency of the waste hard-shell power lithium battery, the battery activity cannot be fundamentally restored or improved, false fatigue of an electron is eliminated only by a special formation process, the activity of an electron surface layer is improved, and the real performance of the electron and a battery cell is restored; the method is initial at home and abroad; the index consistency of the single battery processed by the method is improved to 85% from 40% and is in an advance level in industry; and by the technology, the capacity consistency of the water power lithium battery is greatly improved, and the grouping rate and the application rate during secondary usage can be nearly doubled.

Owner:杜文龙

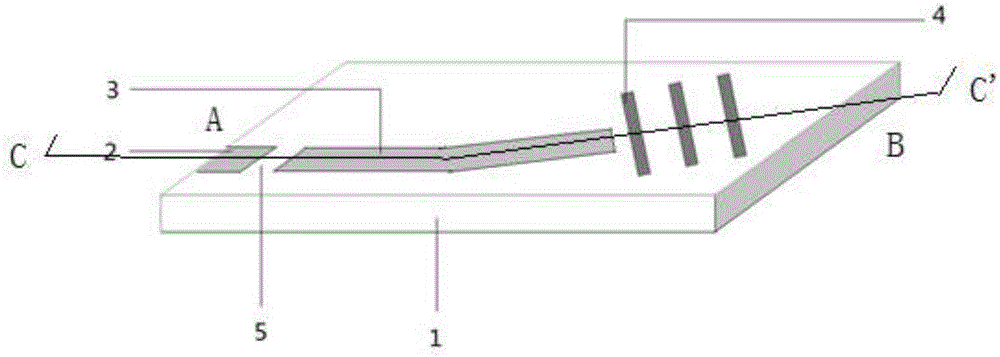

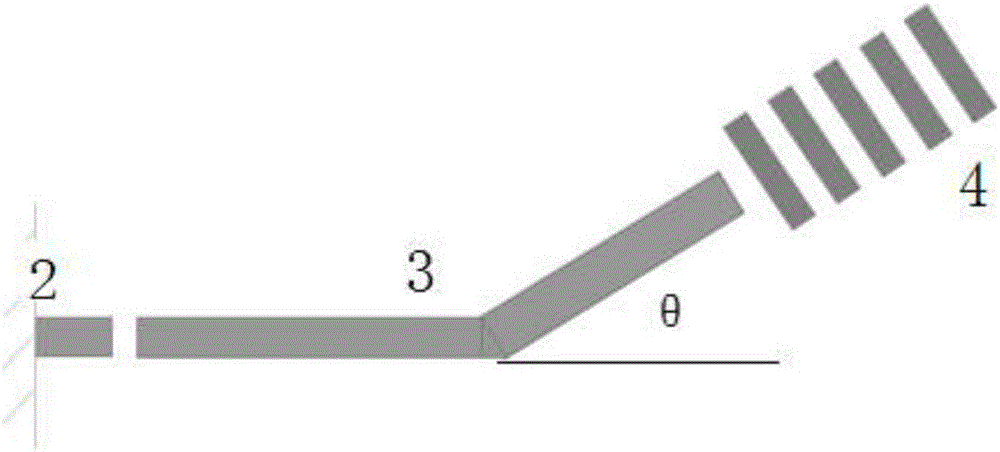

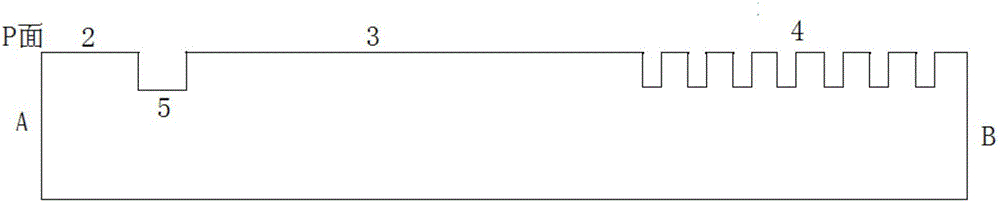

Mode-locked semiconductor laser with stable wavelength

InactiveCN105742956AReduce mistakesSimple processLaser detailsSemiconductor lasersGratingSemiconductor package

The invention provides a mode-locked semiconductor laser with a stable wavelength, and relates to the technical field of semiconductor optic electronics. The mode-locked semiconductor laser with the stable wavelength comprises a saturated absorption region on the basis of a semiconductor laser chip, a total reflection film, a gain region and an optical grating, wherein the total reflection film is arranged at one side of the saturated absorption region; the optical grating is arranged at the light outlet part of the other side and has a stable wavelength output; and wavelength selection is carried out. The problems of the mode-locked semiconductor laser that wavelength is unstable when light is output, and drift is liable to cause are solved; stabilization of the output wavelength is achieved in multiple wavelength selection processes; the technology is easy to implement; the operation is simple; and the mode-locked semiconductor laser becomes a miniature portable high-efficiency, energy-saving and environment-friendly novel light source.

Owner:BEIJING UNIV OF TECH

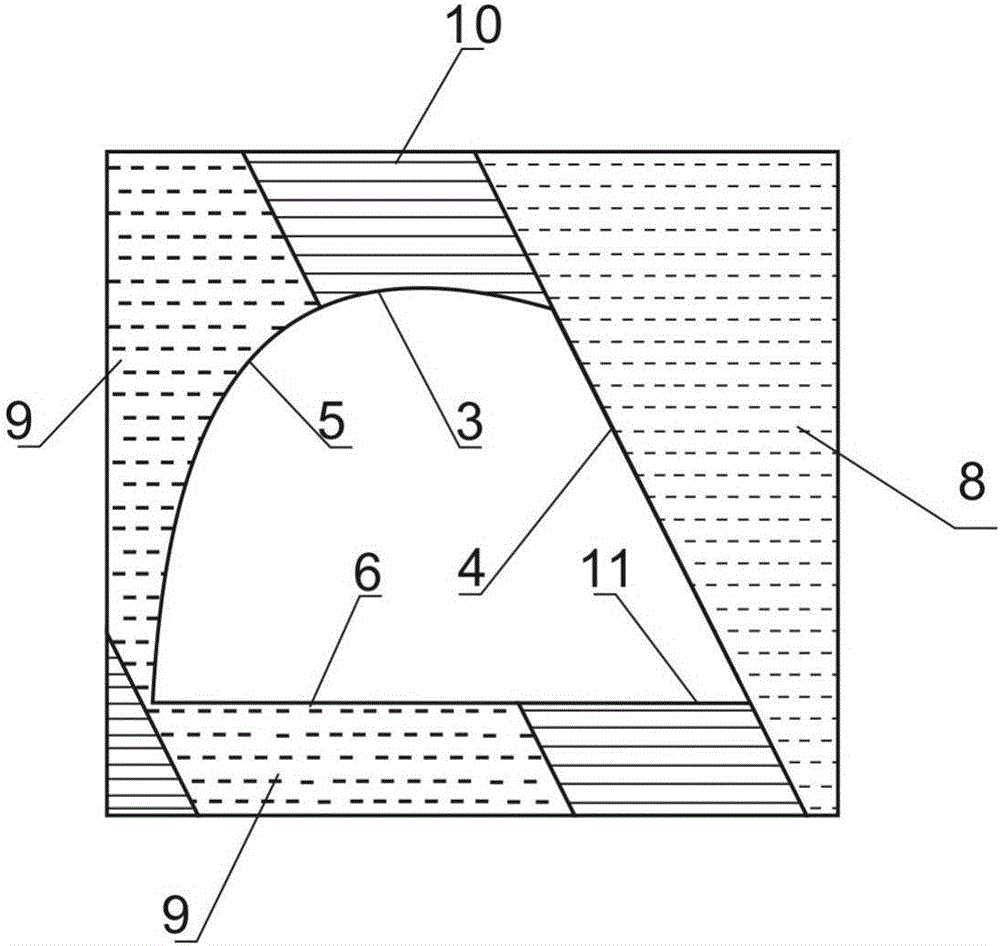

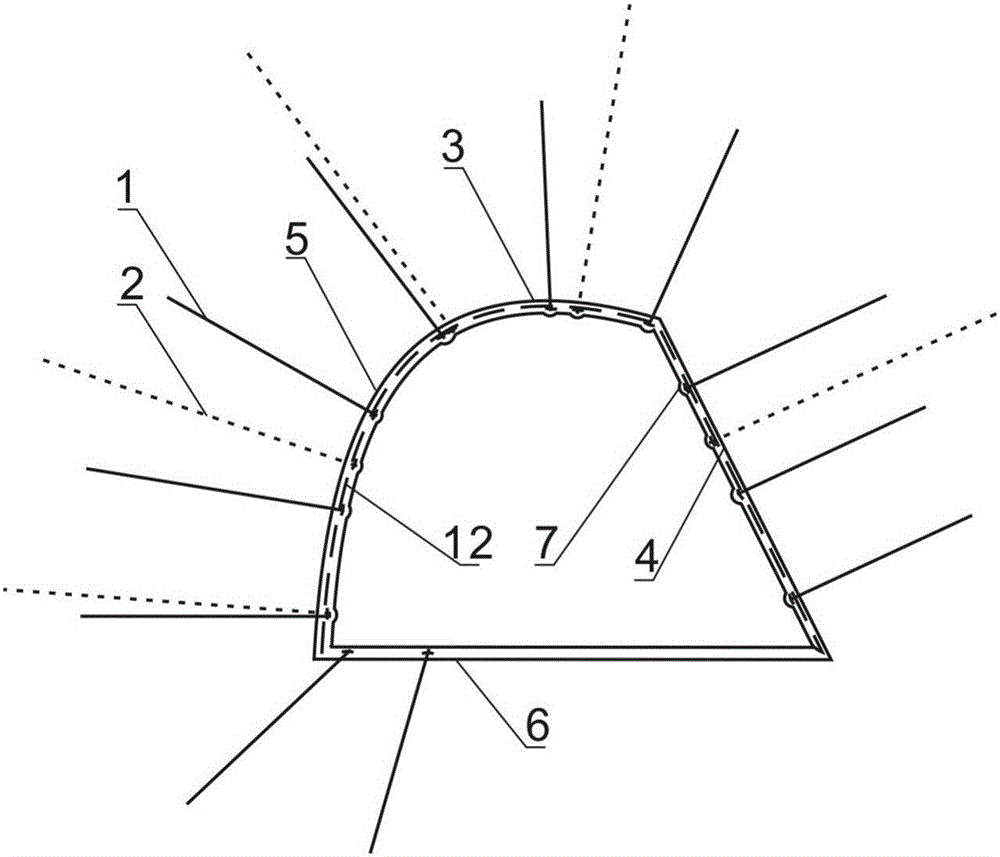

Facility and process for stably supporting steeply inclined mining roadway surrounding rock

InactiveCN106761867ARich mining theoryExpand core technology research fieldsUnderground chambersTunnel liningEngineeringClerestory

The invention discloses a facility and process for stably supporting a steeply inclined mining roadway surrounding rock. A roadway cross section of a mining roadway is an inclined wall arch, the portion above the mining roadway is an arch apex, a top plate is an inclined wall, a base plate is an arched reverse bottom, and a roadway bottom surface is located below the arch apex and is divided into a next section coal seam and a flat bottom. The supporting facility comprises an anchor net support formed by anchor rods, anchor cables, steel belts and metal nets and a closed guniting layer on the surface of the roadway. The supporting process comprises the steps of anchor net installation and concrete spraying on the surface of the roadway. For repeated coal-mining affecting gob-side mining roadway, the process utilizes the high-strength anchor rods and the anchor cables, combines with the W-shaped steel belts and the metal nets, then combines with an asymmetrical multi-medium coupled supporting mode for the concrete sprayed on the surface of the roadway and can effectively control roadway deformation, and safe production of the roadway is achieved. The total reserves of steeply inclined coal seams in domestic reserves are 15%-20%, a foundation is laid for coal seam roadway supporting by adopting the process, and the popularization prospect is wide.

Owner:SICHUAN GUANGWANG ENERGY DEV GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com