Laser shock method and laser shock device

A laser shock and laser technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high cost, wide acceptance, poor adaptability to the constraint plane, etc., and achieve the effect of convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

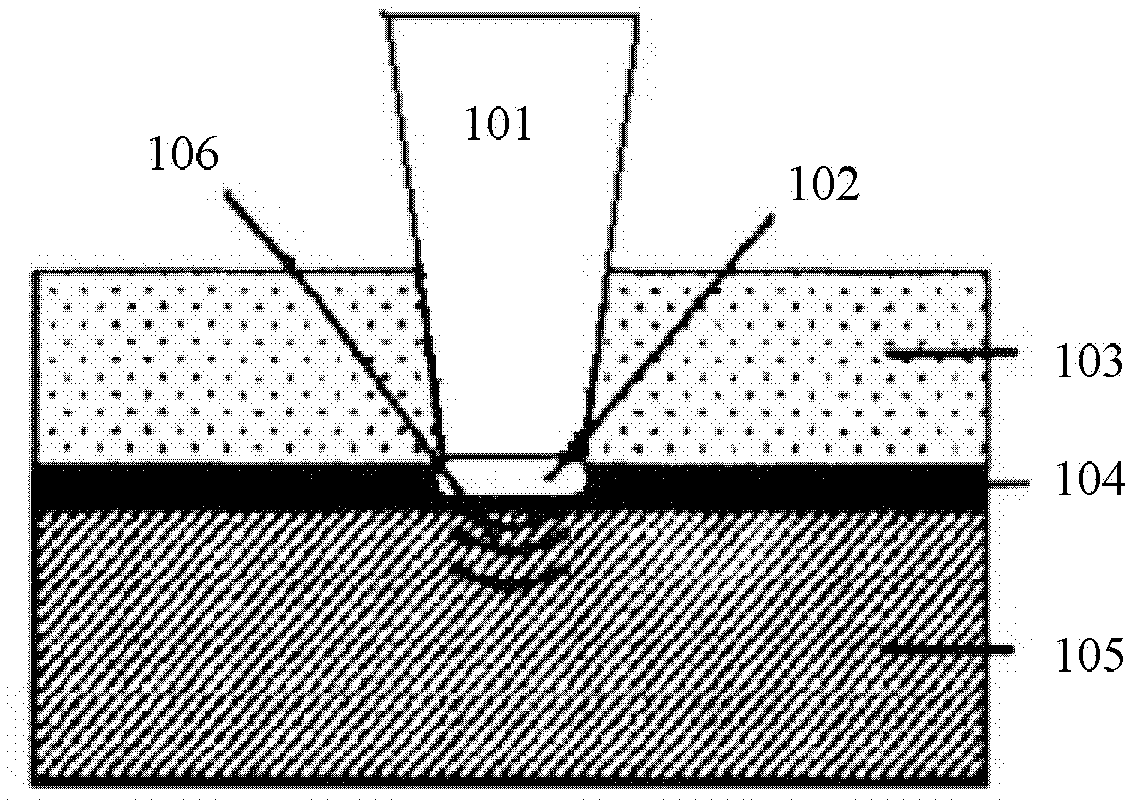

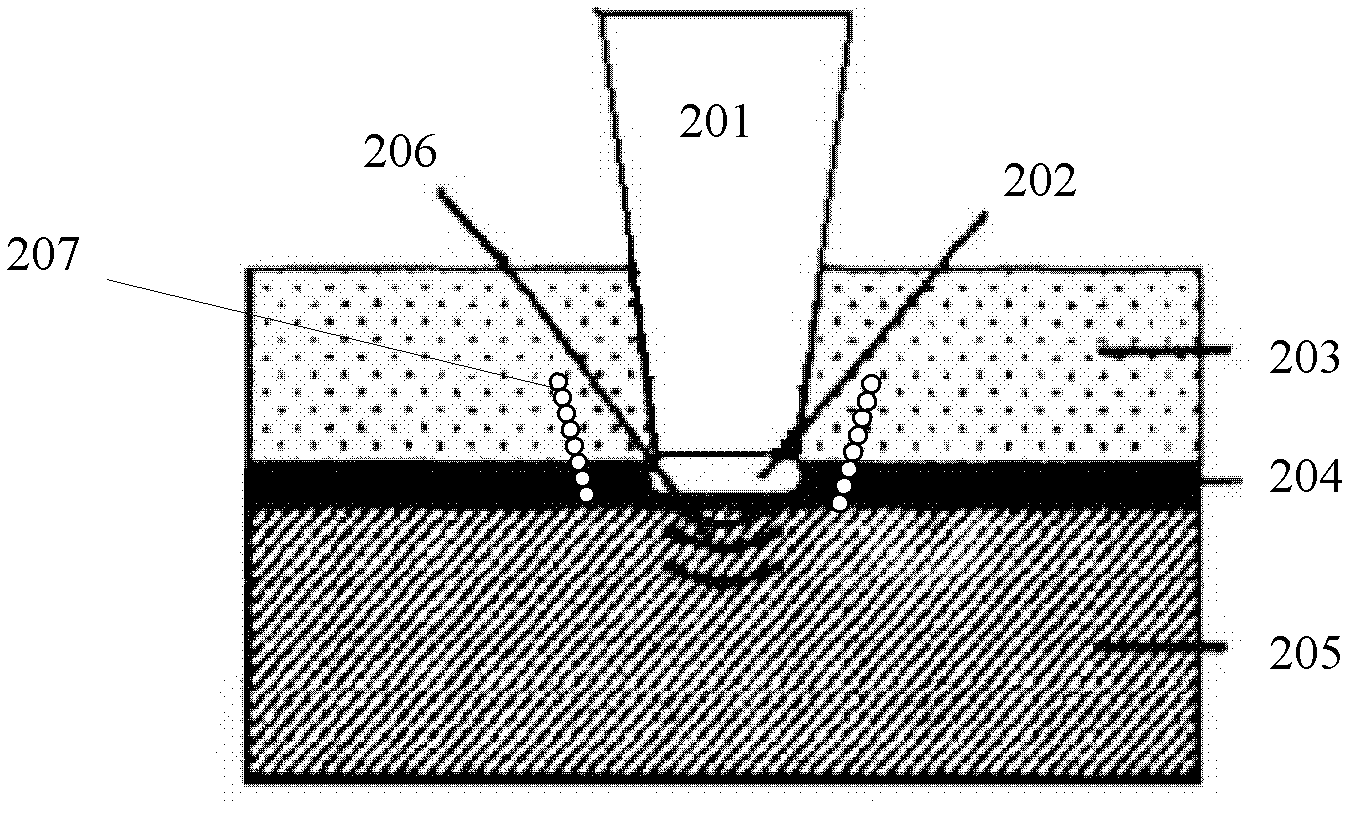

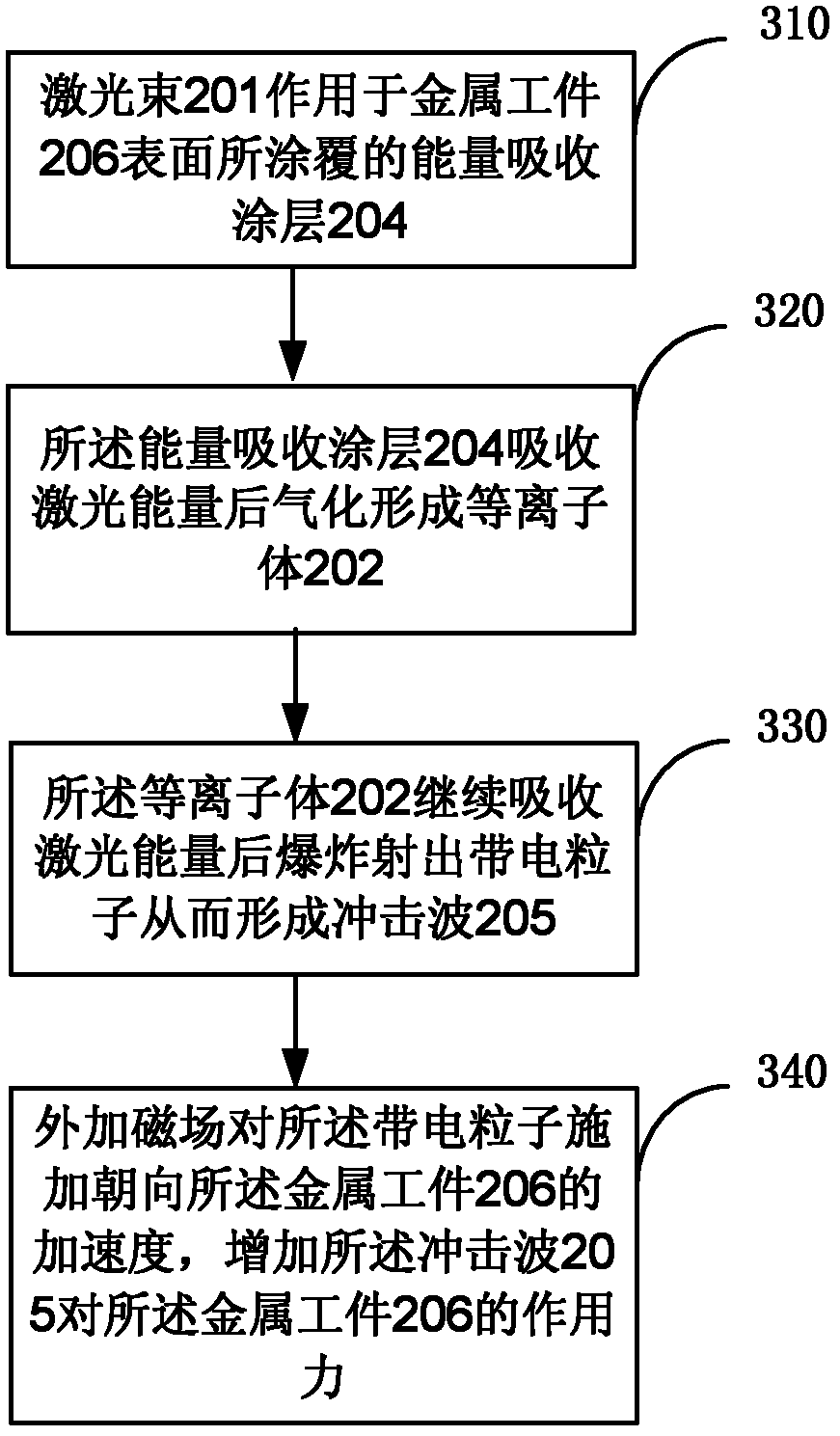

[0046] figure 2 A schematic diagram of a laser shock device provided by the present invention, image 3 The flow chart of the steps of the laser shock method provided by the present invention, such as figure 2 , image 3 As shown, the embodiment of the present invention provides a laser shock method, including:

[0047] Step 310, the laser beam 201 acts on the energy absorbing coating 204 coated on the surface of the metal workpiece 206;

[0048] Step 320, the energy absorbing coating 204 absorbs the laser energy and vaporizes to form a plasma 202;

[0049] Step 330, the plasma 202 continues to absorb the laser energy and then explodes to eject charged particles to form a shock wave 205;

[0050] Step 340 , applying an external magnetic field t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com