Process for manufacturing printed mask paper and mask product thereof

A technology of facial mask paper and printed surface, which is applied in the direction of cosmetic preparations, dressing preparations, pharmaceutical formulas, etc., can solve the problems of difficult to meet individual user needs, monotonous appearance design, no decorative effect, etc., and achieve colorful Appearance effect, beautiful appearance, beneficial to the effect of promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

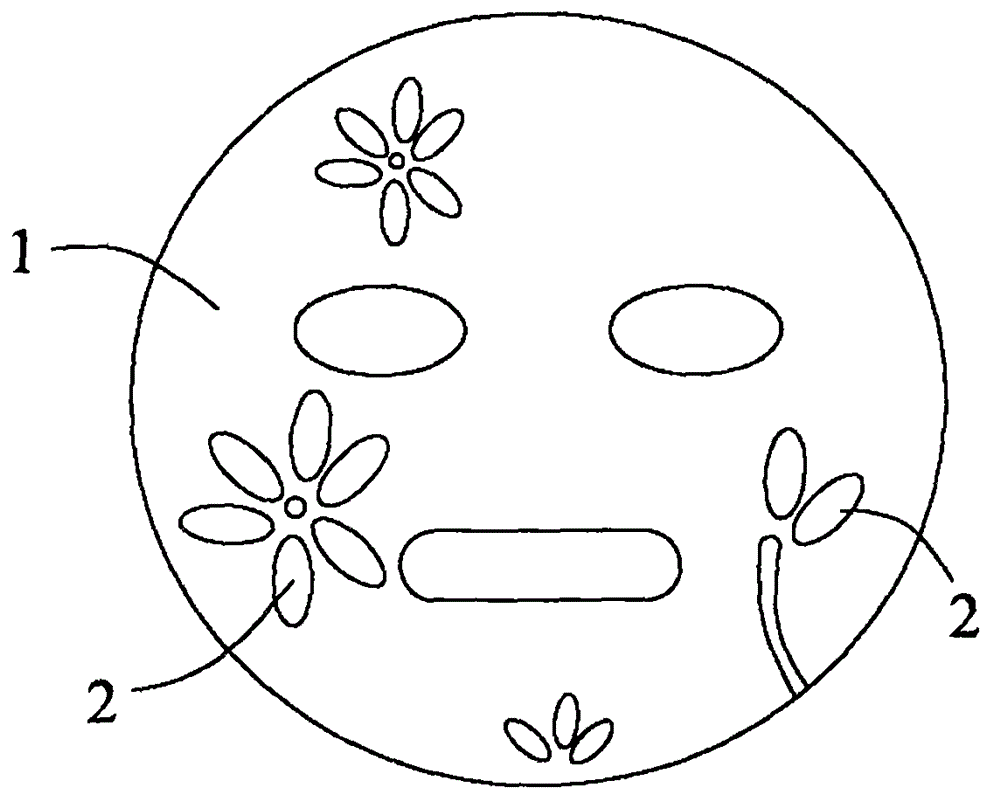

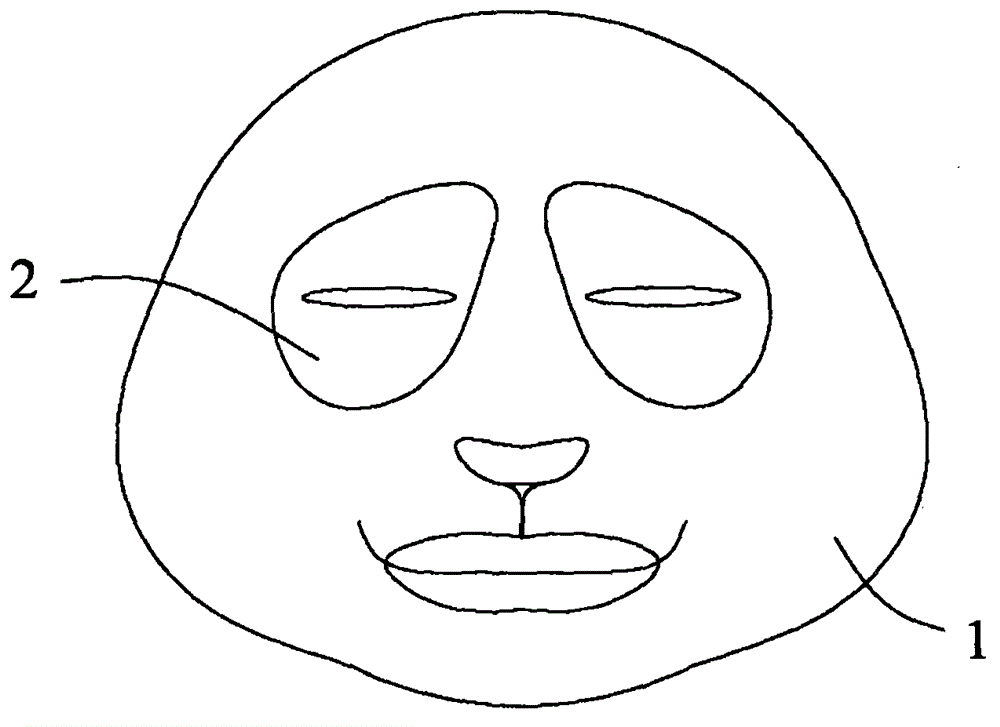

[0025] Example: see figure 1 and figure 2 , the present embodiment provides a process for making printed facial mask, which comprises the following steps:

[0026] (1) Prepare facial mask paper 1;

[0027] (2) Prepare a direct-injection printing machine equipped with environmentally friendly textile printing ink; use environmentally friendly textile printing ink, which is safe and environmentally friendly;

[0028] (3) Mask paper 1 is placed on the direct-jet printing machine;

[0029] (4) start the direct-jet printing machine, print the predetermined pattern on the mask paper, to form the pattern layer 2 on the mask paper 1, and make the printed mask;

[0030] Wherein said steps (1), (2) have no sequence.

[0031] Specifically, the facial mask paper includes a base paper layer and a water-absorbing coating layer laminated with the base paper layer, and patterns are printed on the base paper layer. Preferably, the water-absorbing coating layer is made of non-woven fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com