Water purification and fire extinguishing system

A fire extinguishing system and water purification technology, which is applied in the hydraulic field, can solve the problems of wasting space and the fire extinguishing system does not work well, and achieve the effect of efficient use and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

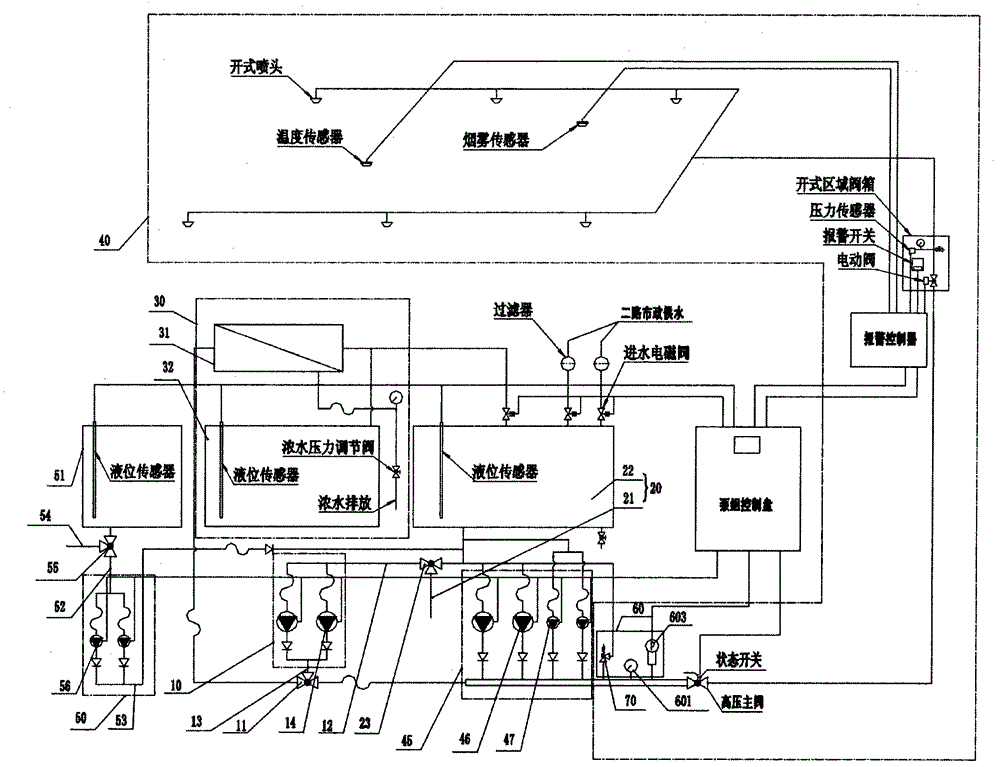

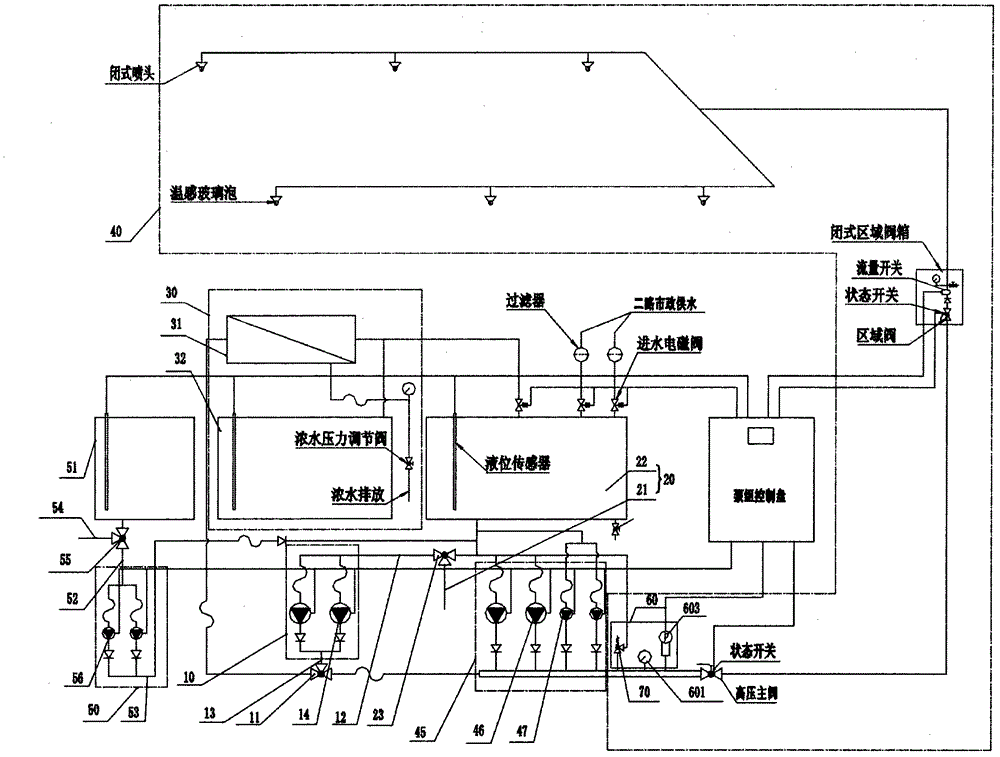

[0025] Embodiments of the present invention provide a water purification and fire extinguishing system, such as figure 1 As shown, the water purification and fire extinguishing system includes a high-pressure pump group 10, the high-pressure pump group includes 1-4 high-pressure pumps 14, and the water inlet 12 of the high-pressure pump group is connected to the water source 20, in order to realize water purification and fire extinguishing functions simultaneously, The embodiment of the present invention also includes a reverse osmosis water purification device 30 and a fire extinguishing pipeline 40 installed in the protected area, and the water outlet 13 of the high-pressure pump group 10 is connected to the reverse osmosis water purification device 20 and the fire extinguishing pipeline respectively through a high-pressure switching valve 11 40. When water purification is required, the water outlet of the high-pressure pump group 10 is switched to communicate with the rever...

Embodiment 2

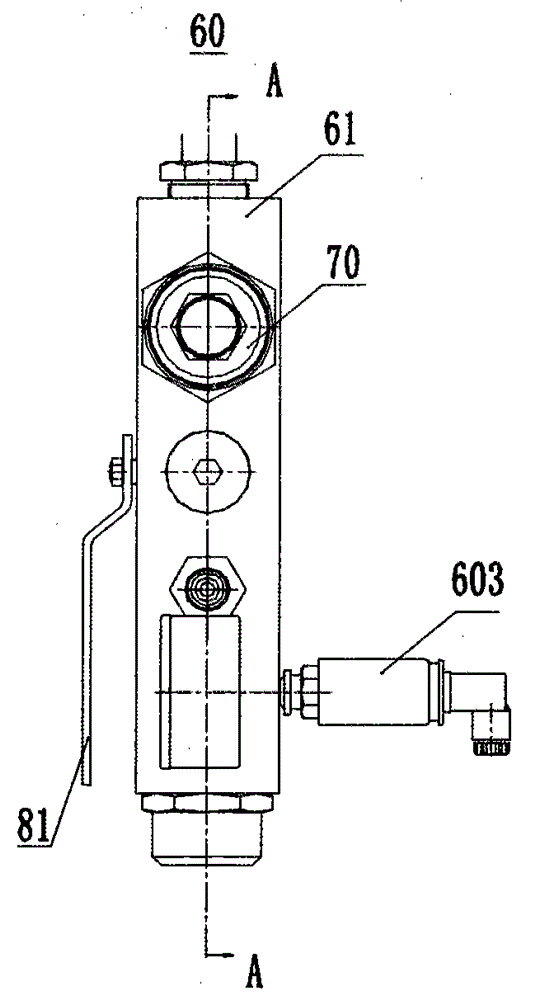

[0038] The embodiment of the present invention provides an integrated combination valve 60, specifically as image 3 As shown, the integrated combination valve 60 includes an integrated valve body 61. The integrated valve body 61 is manufactured in an integrated manner, such as casting an integrally formed integrated valve body, or forging an integrally formed integrated valve body. In order to realize the The integrated valve body is applied to high-pressure water outlet equipment or systems. In the embodiment of the present invention, the integrated valve body is provided with a high-pressure water inlet 62, a high-pressure water outlet 63, and a closed high-pressure water chamber 64 connecting the high-pressure water inlet and the high-pressure water outlet. Connecting the high-pressure water inlet 62 to the water outlet 63 of the high-pressure plunger pump can provide high-pressure water by using the combined valve. For example, if it is used in the fire extinguishing syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com