A roll type reverse osmosis membrane element

A reverse osmosis membrane and membrane element technology, which is applied in the field of reverse osmosis membrane elements and roll-type reverse osmosis membrane elements, can solve the problems of reducing the volume of membrane elements, achieve the effect of length and volume reduction, and is conducive to miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

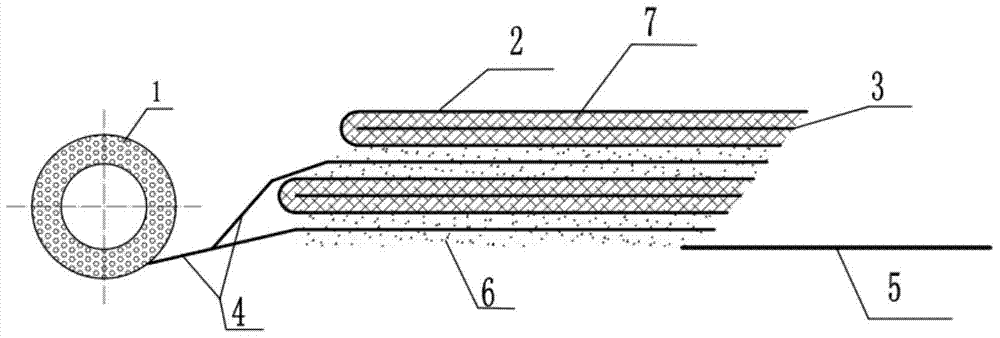

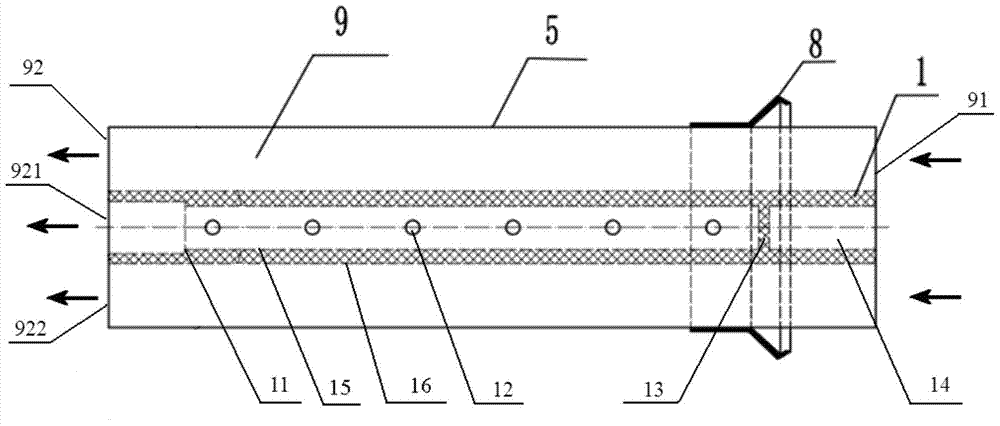

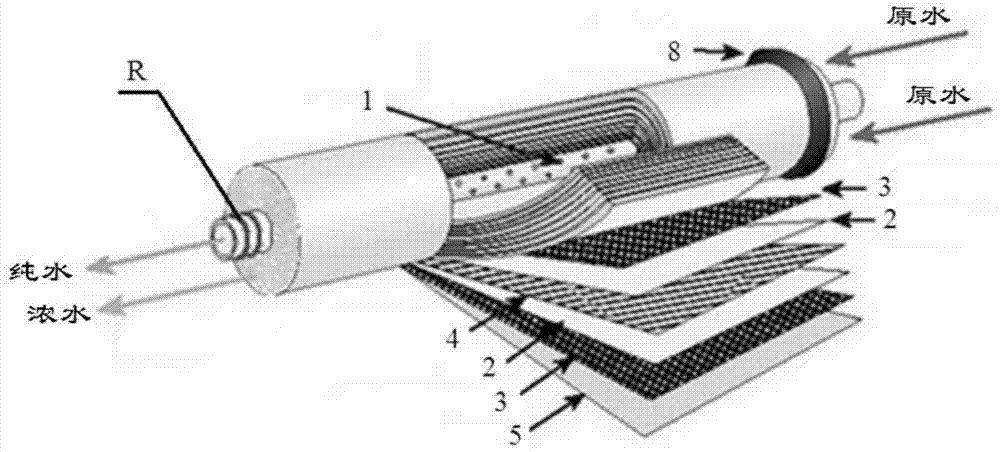

[0025] In this embodiment, a coiled reverse osmosis membrane element is provided, which includes a central water production pipe with a sealed end and a plurality of pure water collection through holes on the pipe, and two sets of purified water coils wound on the central water production pipe. Diaphragm, the water purification membrane is composed of a reverse osmosis membrane, a pure water diversion net, and a water inlet diversion net; the reverse osmosis membrane is folded to form a water inlet channel between its inner surfaces, and the water inlet diversion The net is located in the water inlet flow channel; the water production flow channel is formed between its adjacent outer surfaces, and the pure water diversion net is located in the water production flow channel; the folding line of the reverse osmosis membrane is adjacent to the central water production pipe and parallel to its length direction line ; The water production flow channel only has a pure water outlet fa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com