Bastnaesite beneficiation process

A bastnasite and process technology, which is applied in the field of bastnaestite beneficiation technology, can solve the problems of uneven distribution of rare earth minerals, serious sliming and powdering of bastnaestite, difficult recovery of rare earth, and the like. Guarantee the effect of rare earth recovery rate, rare earth grade and recovery rate improvement, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment one adopts the inventive method

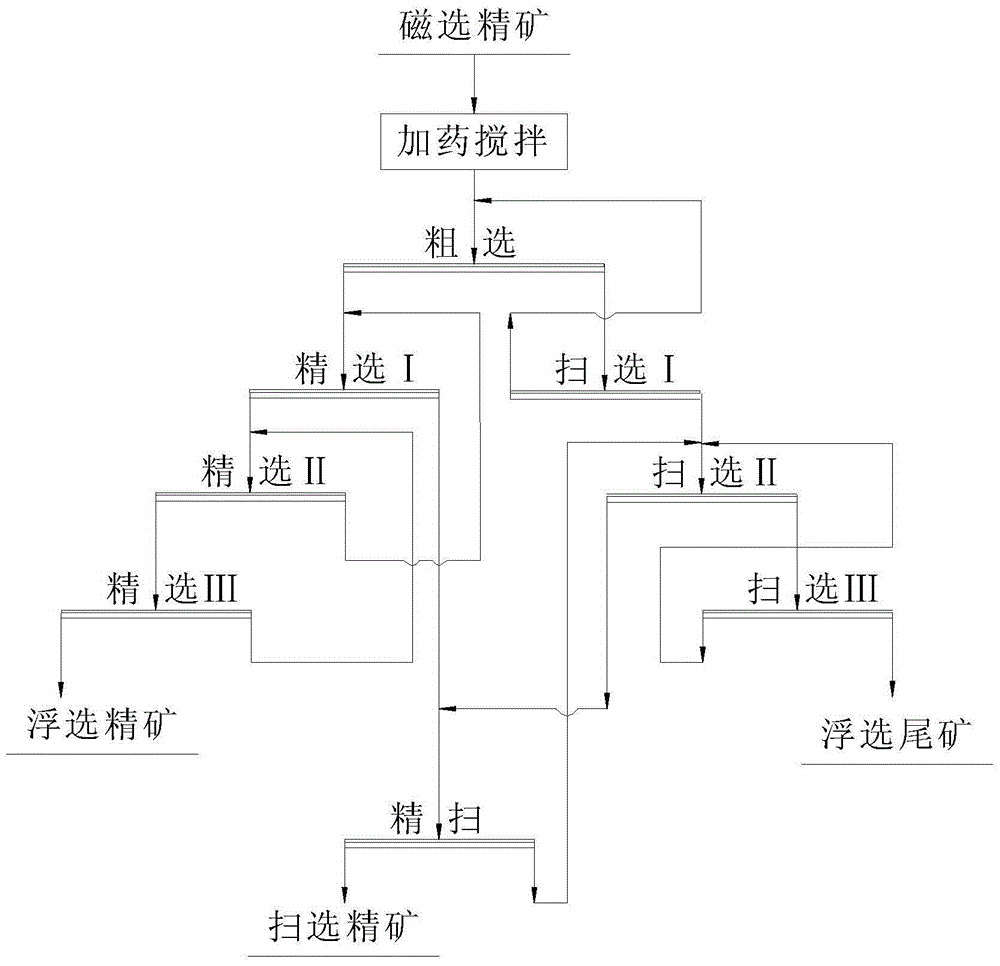

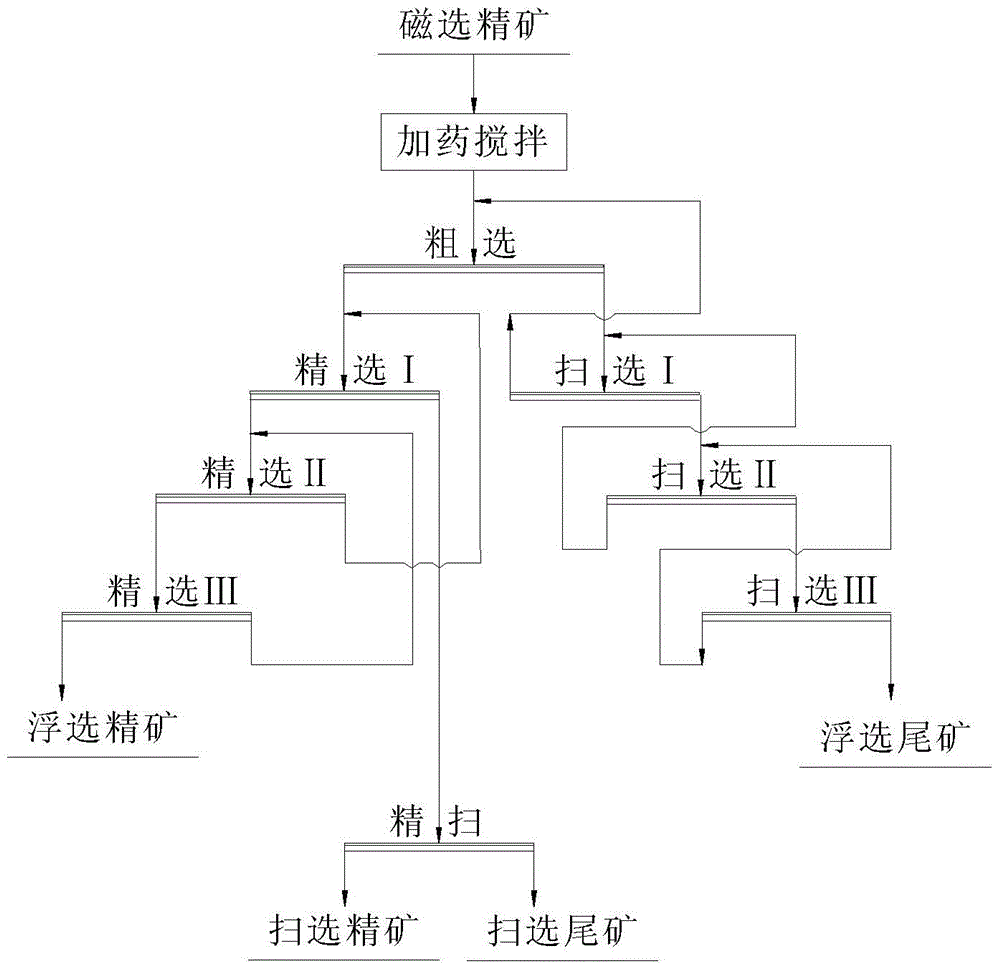

[0053] The raw ore is crushed, passed through a circular vibrating sieve with an aperture of 20mm, and the on-screen material returns to crushing, and then passes through three stages (5mm, 1.5mm and 0.15mm) of sieving and grinding in turn, and the mineral particle size obtained through a 200-mesh sieve has a mineral mass fraction of 70 %about. Then it is sent to a weak magnetic separator to remove iron under a magnetic field strength of 0.5T. The pulp after iron removal is sent to a four-stage strong magnetic separator for strong magnetic separation. The magnetic field strength is 1.2T, and the four-stage strong magnetic separation obtains The ore concentrate grade is about 5%, and then it is concentrated by inclined plate to concentrate the pulp concentration to about 40%, and it is directly sent to the flotation process. The flotation adopts such as figure 1 The process shown is operated, and the flotation agents are comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com