Method for manufacturing W/Cu/CuCrZr composite component

A composite component and component technology are applied in the field of preparation of W/Cu/CuCrZr composite components, which can solve the problems of high production cost and complicated process, and achieve the effects of low cost, simple operation and low temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

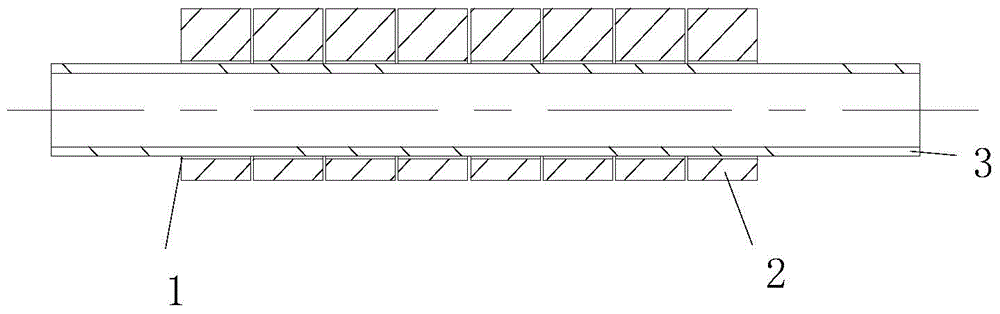

[0025] The W / Cu / CuCrZr composite pipe prepared in this embodiment has the following structure: as figure 1 As shown, the composite tube includes: the outermost tungsten tube layer, which is composed of multiple tungsten blocks 2 with through holes in the middle; oxygen-free copper fixed on the inner surface of each through hole of the tungsten block 2 Layer 1, the oxygen-free copper layer 1 is the copper tube connecting multiple tungsten blocks together; and the CuCrZr tube 3 sleeved and fixed on the inner surface of the oxygen-free copper layer 1; the channel in the CuCrZr tube is used as a cooling water channel.

[0026] The specific preparation method is as follows:

[0027] 1) Preparation of W / Cu composite member Refer to the preparation method of W / Cu composite member described in the patent application with publication number CN102794612A.

[0028] 2) Workpiece treatment: clean the W / Cu composite component and the CuCrZr tube loosely fitted with the inner diameter of th...

Embodiment 2

[0034] The W / Cu / CuCrZr composite tube prepared in this embodiment has the following structure, including: the outermost tungsten tube layer, which is composed of multiple tungsten blocks 2 with through holes in the middle; fixed on the tungsten block 2 The oxygen-free copper layer 1 on the inner surface of each through hole, the oxygen-free copper layer 1 is the copper tube that connects multiple tungsten blocks together; the Ni layer plated on the surface of the oxygen-free copper layer 1, and the Ni layer is sleeved and fixed on the Ni layer CuCrZr tube 3 on the inner surface; wherein the channels in the CuCrZr tube serve as cooling water channels.

[0035] The specific preparation method is as follows:

[0036] 1) Preparation of W / Cu composite member Refer to the preparation method of W / Cu composite member described in the patent application with publication number CN102794612A.

[0037] 2) Workpiece treatment: Electroless plating of 0.02mm Ni layer on the inner surface of...

Embodiment 3

[0043] The W / Cu / CuCrZr composite tube prepared in this embodiment has the following structure, including: the outermost tungsten tube layer, which is composed of multiple tungsten blocks 2 with through holes in the middle; fixed on the tungsten block 2 Oxygen-free copper layer 1 on the inner surface of each through hole of each through hole, and oxygen-free copper layer 1 connects a plurality of tungsten blocks; Ni layer, Mn layer and Ti layer in sequence), and the CuCrZr tube 3 sleeved on the inner surface of the oxygen-free copper layer 1 and coated with a Ni-Mn-Ti layer; wherein the channel in the CuCrZr tube is used as a cooling water channel.

[0044] The specific preparation method is as follows:

[0045] 1) Preparation of W / Cu composite member Refer to the preparation method of W / Cu composite member described in the patent application with publication number CN102794612A.

[0046] 2) Workpiece treatment: chemically plate a 0.2mm Ni-Mn-Ti layer on the outer surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com