Working method of auto-complete checking device

An inspection device and automatic completion technology, applied to measuring devices, measuring device casings, conveyor control devices, etc., can solve problems such as wasting manpower, increasing defective rates, and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

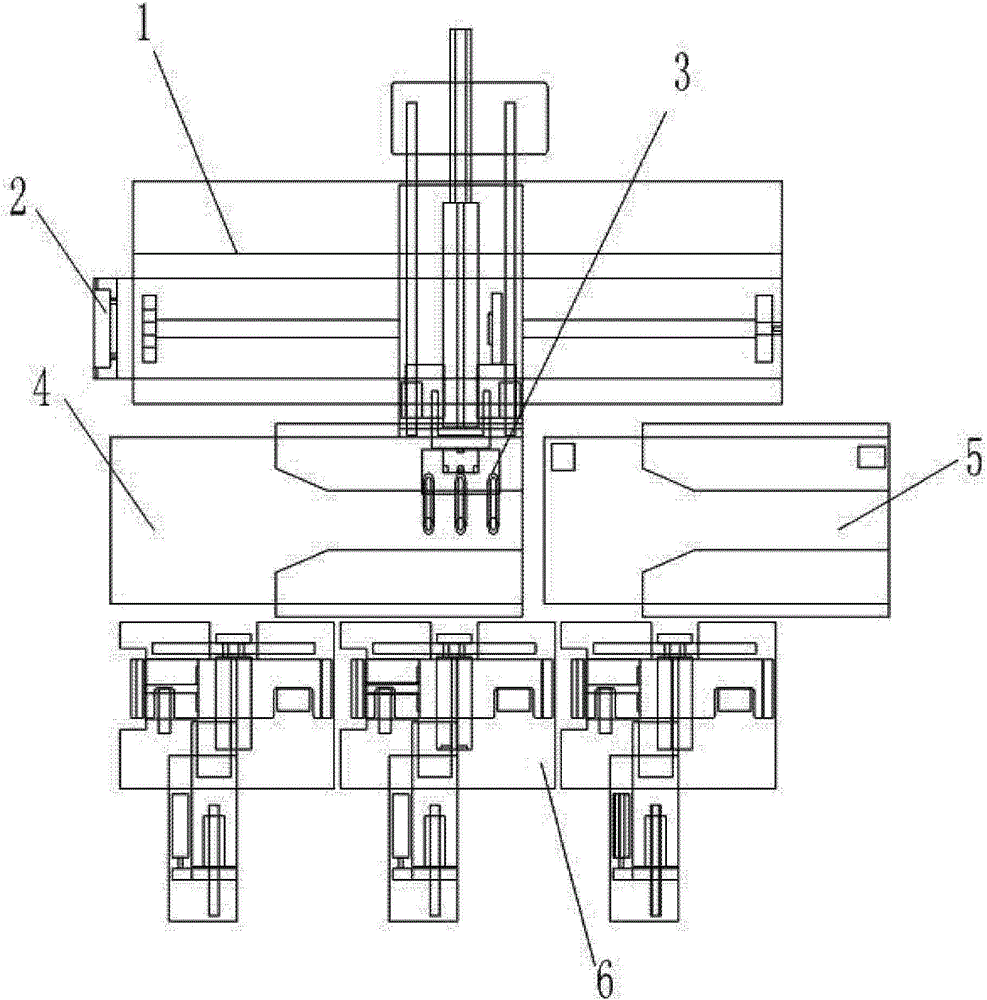

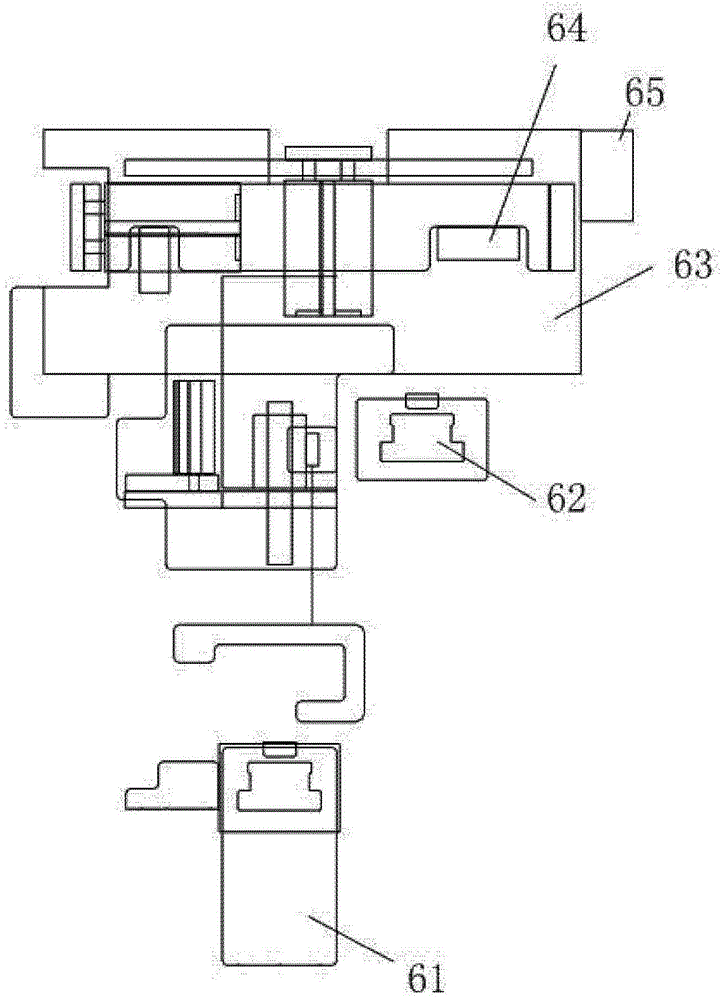

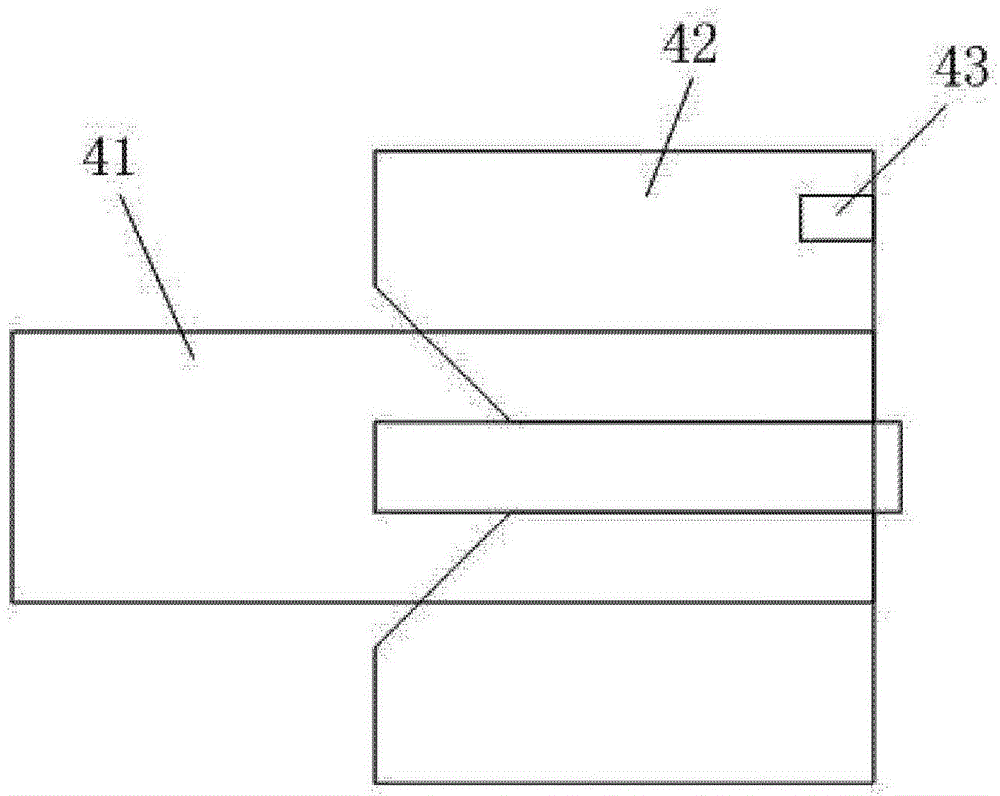

[0012] like figure 1 As shown, the automatic completion inspection device includes a base, and the base is distributed with an upper area, a middle area and a lower area, and a parallel slide rail 1 is arranged on the upper area, and the slide rail 1 is provided with a motor driven by a motor 2. The cylinder is provided with a manipulator 3 that moves through the cylinder in the middle area and the lower side area; the middle area is distributed with a front transmission waiting area 4 and a rear transmission waiting area 5 side by side, such as image 3 As shown, the front transmission waiting area is composed of a front conveyor belt 41, a front product waiting area 42, and a first sensor 43. A passing drive device is arranged in the front conveyor belt 41, and a front product waiting area 42 is arranged at the end of the front conveyor belt 41. A first sensor 43 is installed on the product waiting area 42, Figure 4 As shown, the rear transmission waiting area is compo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap