BaTiO3-based PTC (Positive Temperature Coefficient) ceramic and preparation method thereof

A technology for ceramics and ceramic raw materials, which is applied in the field of component design and preparation of doped BaTiO3-based PTC ceramics. It can solve the problems of segregation of doping elements, etc., and achieve increased doping concentration, improved PTC performance, and small grain size. and even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

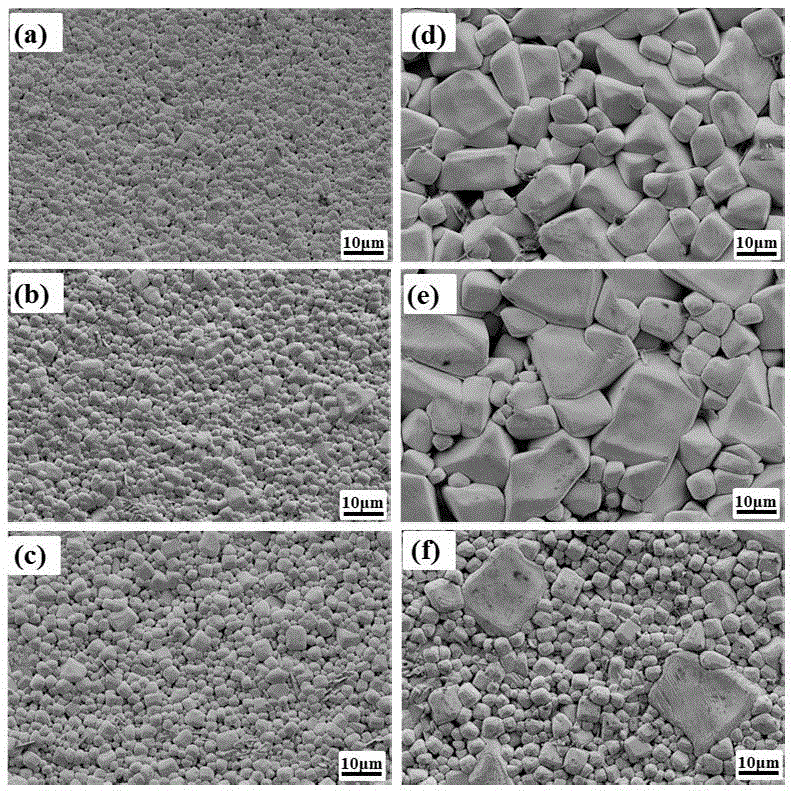

Image

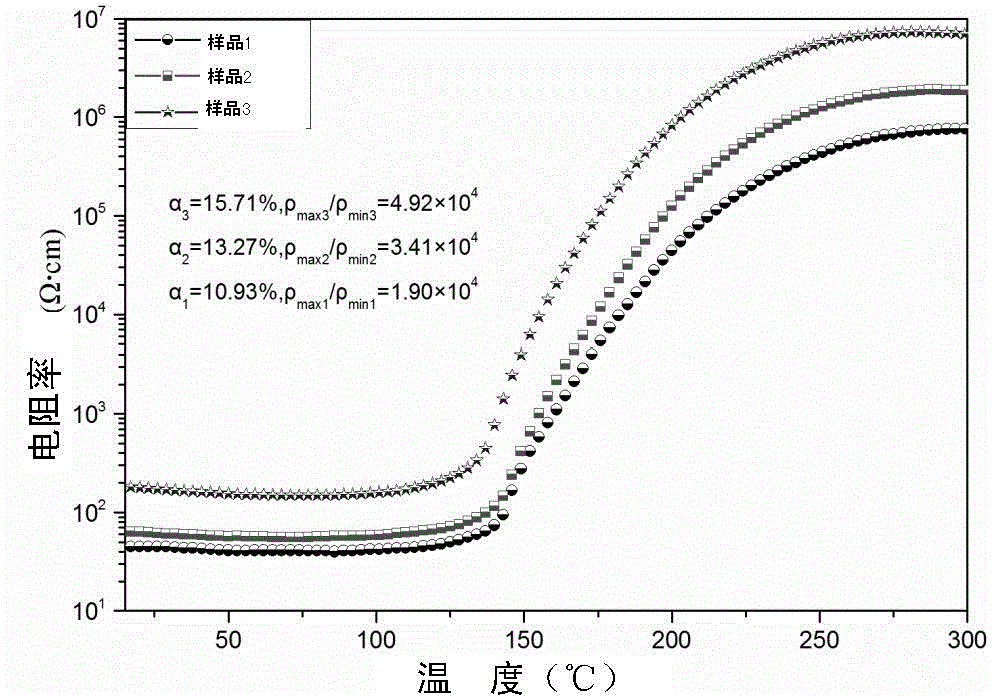

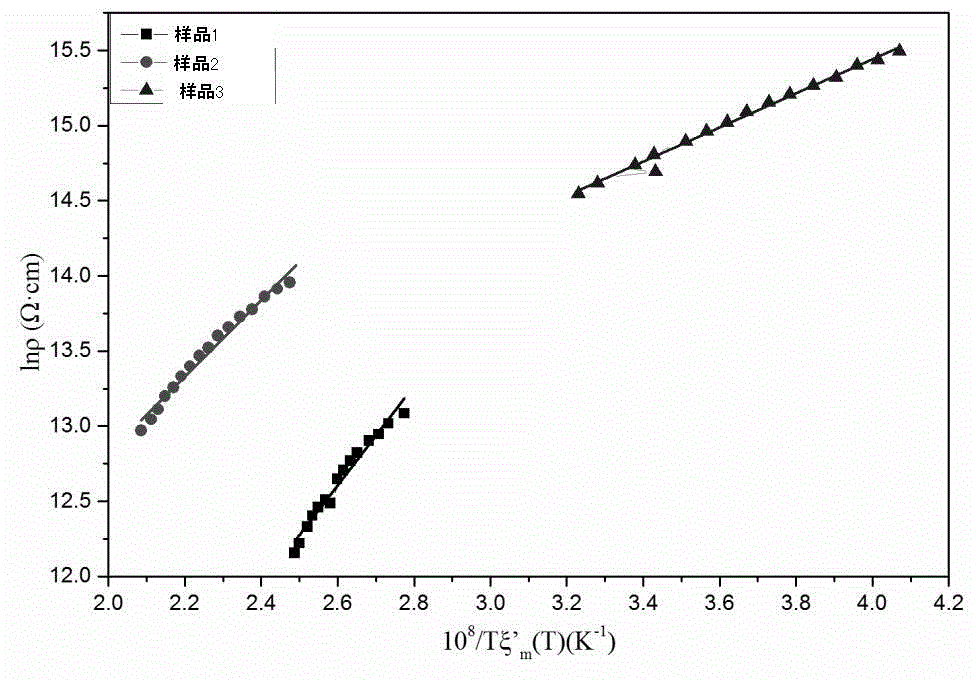

Examples

Embodiment 1

[0066] Step 1: BaTiO 3 Synthesis of main ingredients

[0067] 1) BaCO 3 、TiO 2 Mix according to the molar ratio of 1:1, and carry out planetary ball milling for the mixed powder, the ball milling time is 8h, the speed is 400r / min, and ZrO 2 The balls are milled particles, and alcohol is used as the milling medium to obtain mixture A. Among them, m (球磨粉末) :m (球磨颗粒) :m (球磨介质) =1:3:1.2;

[0068] 2) Dry the ball-milled powder (100°C, 10h), sieve, and pre-fire at 1150°C for 2h to synthesize BaTiO 3 Main material; Step 2: introduction of doping elements

[0069] 1) BaTiO in step 1 3 Main ingredients according to formula Y 0.01 -Mn 0.0006 -(Ba 0.965 Ca 0.035 )TiO 3 with Y 2 o 3 , MnCO 3 , CaTiO 3 , AST (Al 2 o 3 , SiO 2 、TiO 2 ) powders were mixed, ball milled (the ball milling conditions were the same as step 1), dried (100° C., 10 h), and sieved to obtain mixture B. where Al 2 o 3 , SiO 2 、TiO 2 As a sintering aid, its molar percentages are 0.1 at.%, 1 at...

Embodiment 2

[0096] Step 1: BaTiO 3 Synthesis of main ingredients

[0097] 1) BaCO 3 、TiO 2 Mix according to the molar ratio of 1:1, and carry out planetary ball milling for the mixed powder, the ball milling time is 8h, the speed is 400r / min, and ZrO 2 The balls are milled particles, and alcohol is used as the milling medium to obtain mixture A. Among them, m (球磨粉末) :m (球磨颗粒) :m (球磨介质) =1:3:1.2;

[0098] 2) Dry the ball-milled powder (100°C, 10h), sieve, and pre-fire at 1150°C for 2h to synthesize BaTiO 3 Main material; Step 2: introduction of doping elements

[0099] 1) BaTiO in step 1 3 Main ingredients according to formula Y 0.005 -Mn 0.0006 -(Ba 0.965 Ca 0.035 )TiO 3 with Y 2 o 3 , MnCO 3 , CaTiO 3 , AST (Al 2 o 3 , SiO 2 、TiO 2 ) powders were mixed, ball milled (the ball milling conditions were the same as step 1), dried (100° C., 10 h), and sieved to obtain mixture B. where Al 2 o 3 , SiO 2 、TiO 2 As a sintering aid, its molar percentages are 0.1 at.%, 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com