A kind of preparation method of silicon oxynitride fluorescent powder

A technology of silicon oxynitride and silicon oxide, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as low luminous intensity, irregular shape, rapid growth and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention discloses a preparation method of silicon oxynitride fluorescent powder, comprising the following steps: step a) coating metal cations on the surface of nano microspheres, and obtaining a precursor powder after heat treatment, wherein the metal cations include matrix metal cations and luminescent metals Cation, the nanospheres are silicon oxide nanospheres, silicon nitride nanospheres, silicate nanospheres, core-shell hybrid nanospheres with silicon oxide as the shell, silicon nitride as the shell The core-shell hybrid nanospheres of the shell or the core-shell hybrid nanospheres with silicate as the shell; step b) coating the surface of the precursor powder with H 3 BO 3 , get H 3 BO 3 Coated precursor powder; step c) the H 3 BO 3 The coated precursor powder is reacted in a reducing atmosphere to obtain a h-BN coated precursor powder; step d) sintering the h-BN coated precursor powder at 1300-1650°C to obtain silicon oxide Nitride phosphor.

[0044]...

Embodiment 1

[0058] Will use 0.5g SiO with a diameter of about 280 nm prepared by 2 Ball, Sr 2+ and Eu 3+ The nitrate solution and a certain amount of urea are mixed together to prepare a uniform solution: the Sr in the solution 2+ (Eu 3+ ) concentration is 0.002mol / L, and the concentration of urea is 0.2mol / L;

[0059] Then the solution was heated to 85°C, kept at this temperature for 6 hours, then the obtained solution was suction filtered, dried, and sintered in the air at 500°C, and the sintered powder was mixed into 60°C H 3 BO 3 solution (dissolved with 2.5g H 3 BO 3 powder), then naturally lowered to 5°C under stirring, filtered, and dried;

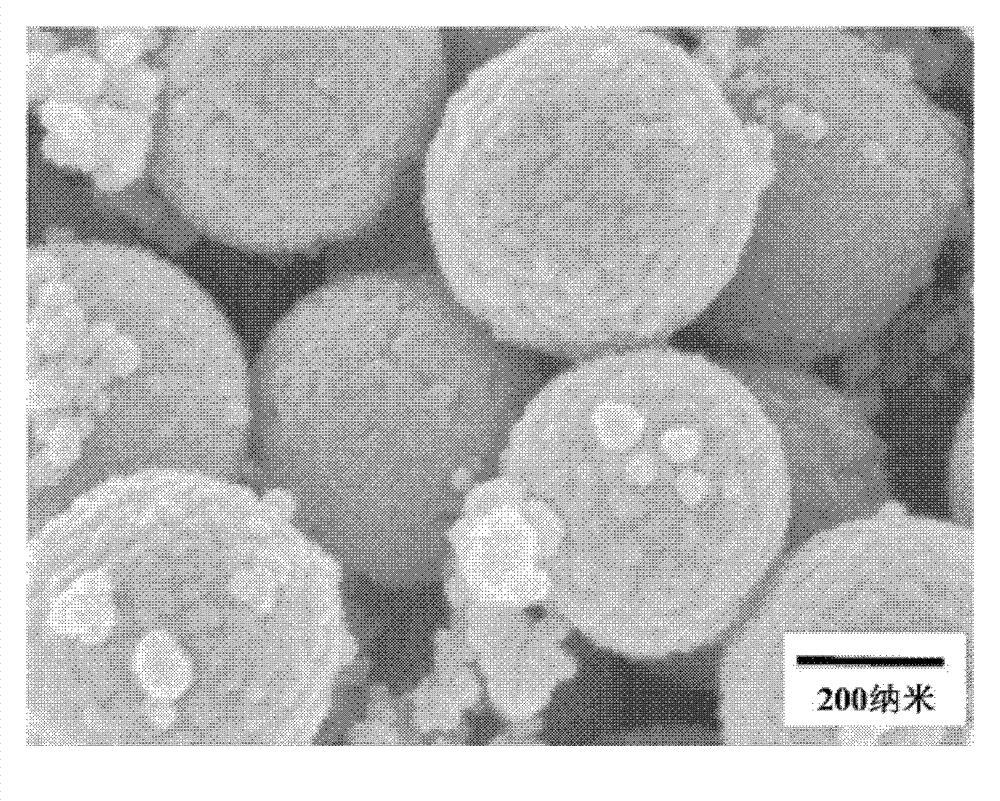

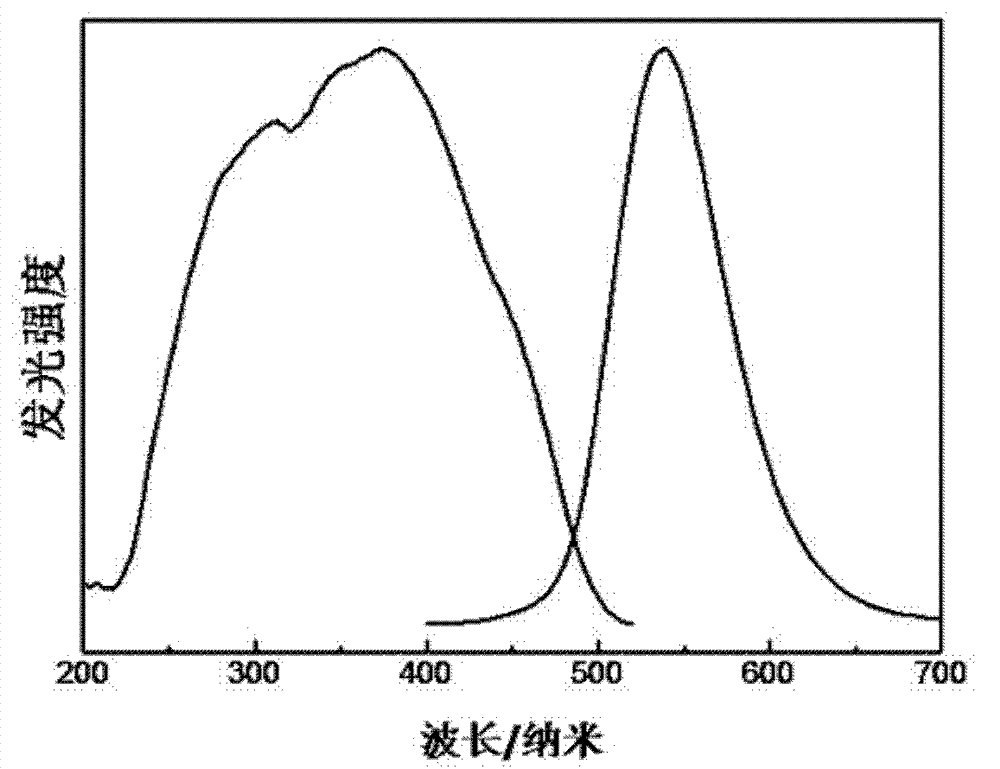

[0060] Put the obtained powder into a BN boat, first raise the temperature to 1000°C for 2 hours in a 300ml / min ammonia gas flow, and then keep it at 1400°C for 8 hours to obtain spherical SrSi 2 o 2 N 2 :Eu 2+ Green fluorescent powder with a particle size of about 300nm.

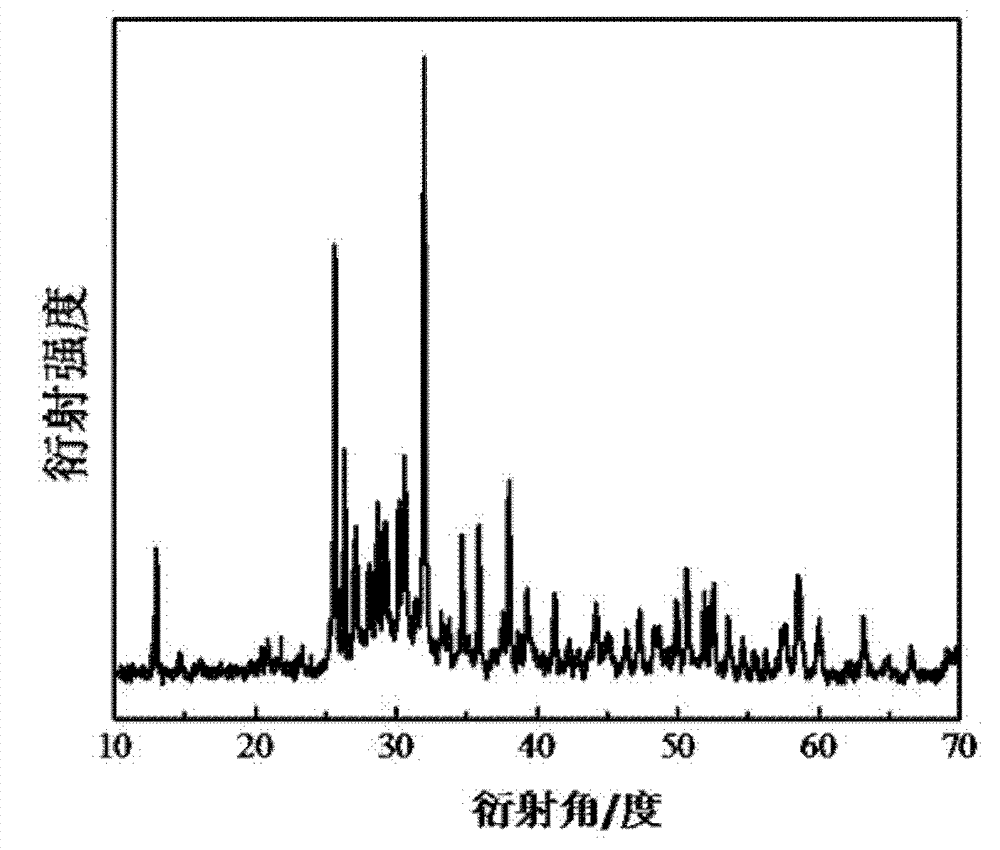

[0061] Utilize XRD (X-ray diffractometer) to test and ana...

Embodiment 2

[0063] Will use 0.5g SiO with a diameter of about 280 nm prepared by 2 Ball, Sr 2+ and Eu 3+ The nitrate solution and a certain amount of urea are mixed together to prepare a uniform solution: the Sr in the solution 2+ (Eu 3+ ) concentration is 0.002mol / L, and the concentration of urea is 0.2mol / L;

[0064] Then the solution was heated to 85°C, kept at this temperature for 6 hours, then the obtained solution was suction filtered, dried, and sintered in the air at 500°C, and the sintered powder was mixed into 55°C H 3 BO 3 solution (dissolved with 3.0g H 3 BO 3 powder), then naturally lowered to 5°C under stirring, filtered, and dried;

[0065] Put the obtained powder into a BN boat, first raise the temperature to 1000°C for 2 hours in an ammonia gas flow of 300ml / min, and then keep it at 1400°C for 8 hours (the reducing atmosphere during the heat preservation is NH 3 and CH 4 mixed gas, and CH 4 Concentration of 3 ~ 5vol%), to obtain spherical Sr 2 Si 5 N 8 :Eu ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com