Preparation method of fully-stable tetragonal YSZ target material and ultra-long-life EB-PVD coating

A super-long-life, fully-stabilized technology, applied in the coating process of metal materials, coatings, manufacturing tools, etc., can solve the problems of insufficient life, uneven distribution of stabilizers, etc., and achieve uniform thermal stress release and small grain size , to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

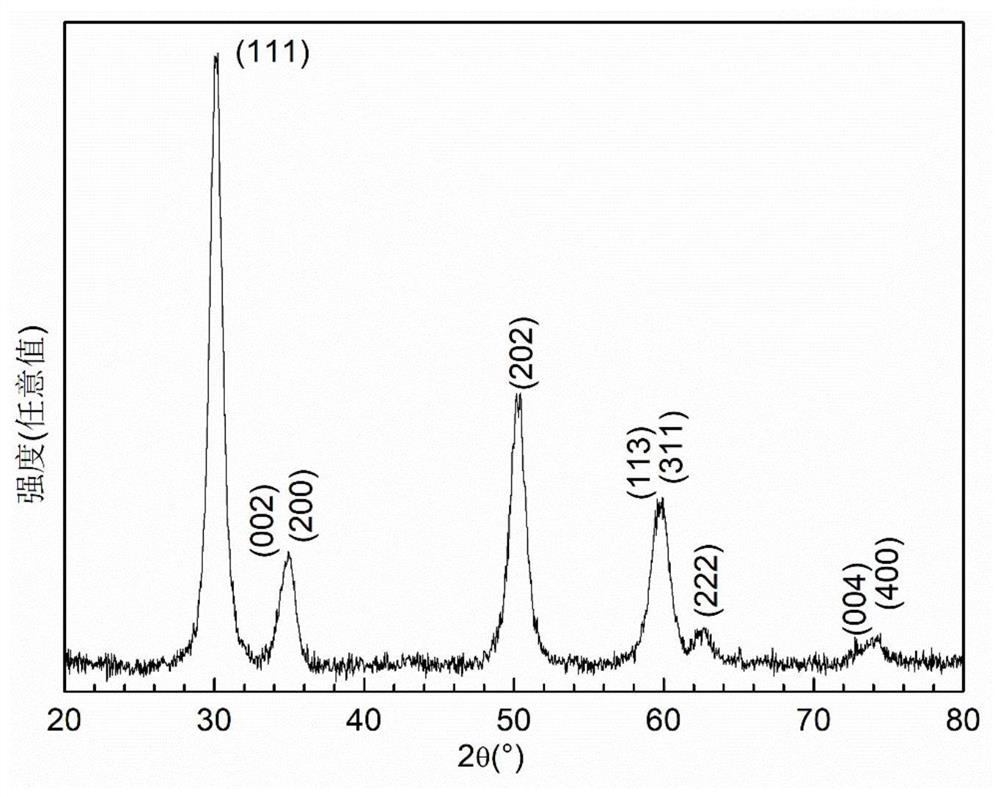

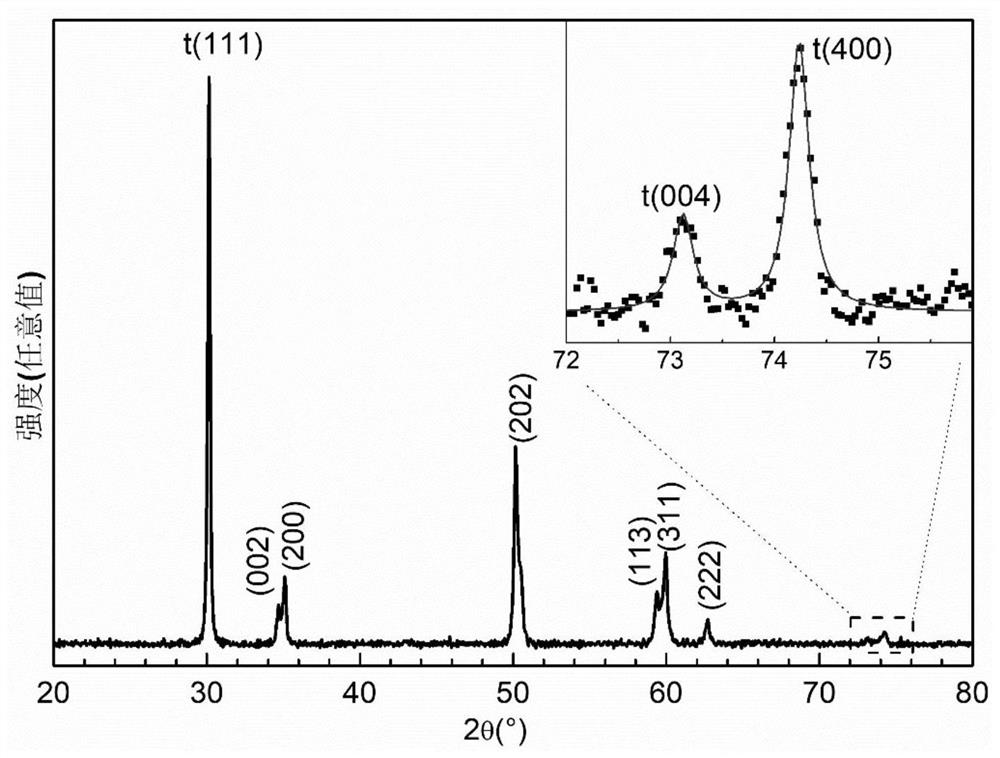

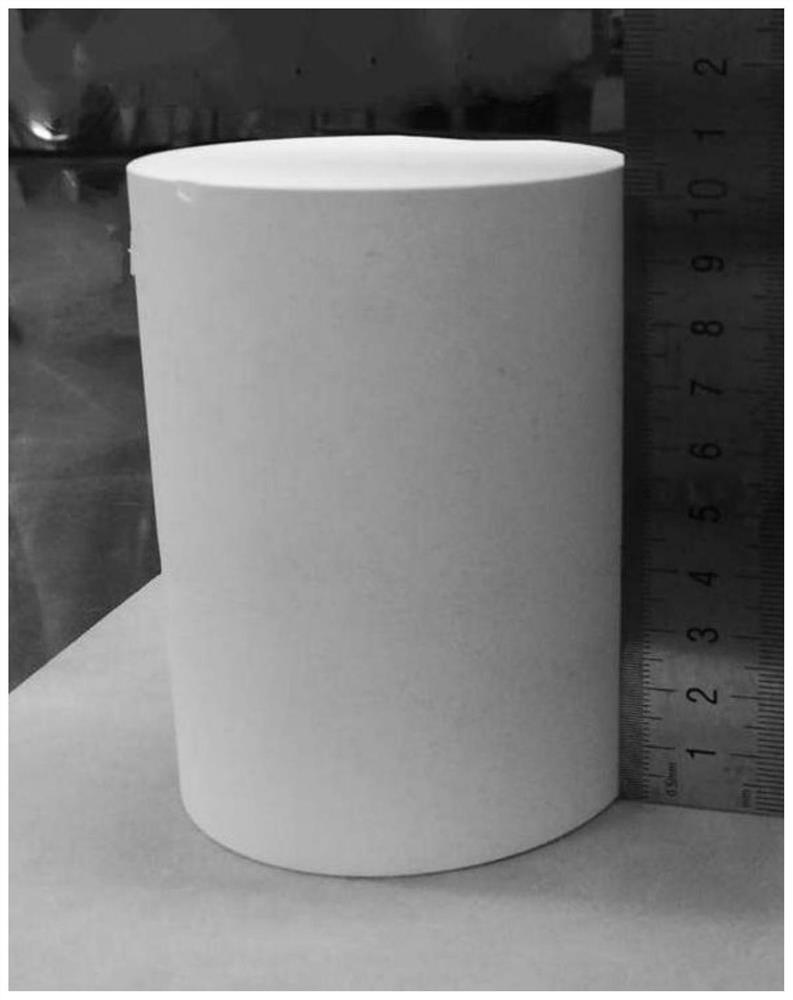

[0047] A preparation method of a fully stabilized tetragonal YSZ target for ultra-long-life EB-PVD coating, comprising the following steps:

[0048] Step 1. Use Zr(NO) with a purity of 99.99% 3 ) 4 ·3H 2 O and Y (NO 3 ) 3 ·6H 2 O is the raw material, the molar ratio Zr (NO 3 ) 4 ·3H 2 O:Y(NO 3 ) 3 ·6H 2 O=0.92:0.08 ingredients, using deionized water as solvent to prepare an aqueous solution with a total concentration of metal ions of 0.2mol / L, magnetic stirring for 1-3h until clear and transparent, then adding additive citric acid hexahydrate and molecular weight of 20000 160g / L of citric acid, 20g / L of polyethylene glycol, and then magnetically stirred to become clear and transparent to obtain a sol; the sol was atomized into a corundum crucible by a pressure atomization method, The atomization pressure was 0.3MPa, and the temperature of the corundum crucible was 500°C; after the sol atomization was completed, the temperature of the corundum crucible was raised to ...

Embodiment 2

[0059] A preparation method of a fully stabilized tetragonal YSZ target for ultra-long-life EB-PVD coating, comprising the following steps:

[0060] Step 1. Use Zr(NO) with a purity of 99.99% 3 ) 4 ·3H 2 O and Y (NO 3 ) 3 ·6H 2 O is the raw material, the molar ratio Zr (NO 3 ) 4 ·3H 2 O:Y(NO 3 ) 3 ·6H 2 O=0.92:0.08 ingredients, using deionized water as solvent to prepare an aqueous solution with a total concentration of metal ions of 0.2mol / L, magnetic stirring for 1-3h until clear and transparent, then adding additive citric acid hexahydrate and molecular weight of 20000 160g / L of citric acid, 20g / L of polyethylene glycol, and then magnetically stirred to become clear and transparent to obtain a sol; the sol was atomized into a corundum crucible by a pressure atomization method, The atomization pressure was 0.3MPa, and the temperature of the corundum crucible was 500°C; after the sol atomization was completed, the temperature of the corundum crucible was raised to ...

Embodiment 3

[0076] A fully stable tetragonal YSZ target prepared in Example 1 is used to prepare an ultra-long-life EB-PVD coating, including: a substrate whose surface coating is a double-layer structure composed of an adhesive layer and a ceramic layer; the ceramic layer adopts The EB-PVD coating spraying process sprays a fully stable tetragonal YSZ target. The spraying process parameters are: substrate heating current 0.2A; heating ingot current 1.3A; substrate temperature 900°C; power 25kW; rotation speed 13r / min; vacuum degree 10 -3 Pa; the substrate is a nickel-based superalloy DD5 with a diameter of 25.4 mm and a thickness of 5 mm; the preparation method of the bonding layer is: after plating Pt on the substrate, it is treated at 1050° C. for 2 hours, and a diffusion layer is formed together with Ni in the substrate; 1080 ℃ gas phase infiltration of Al for 5h, and then heat treatment by two-step diffusion method, that is, heating at 1100℃ for 1h and then heating at 875℃ for 16h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com