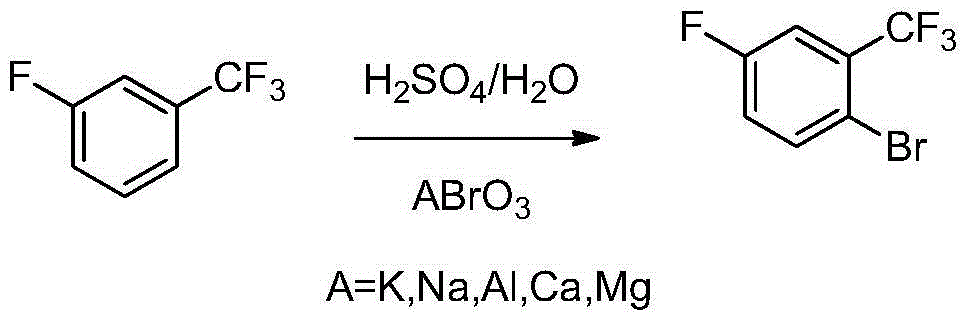

Preparation method of 2-bromine-5-fluorine trifluorotoluene

A technology of fluorotrifluorotoluene and m-fluorotrifluorotoluene, which is applied in the field of organic synthesis, can solve the problems of difficulty in obtaining a brominating reagent, high processing costs, unfriendly environment, etc., and achieves low price, few reaction steps, and easy raw materials. effect of purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 6.00kg of 70% sulfuric acid into a 10L glass reactor, pass through frozen brine, control the temperature below 30°C, add 0.66kg of m-fluorobenzotrifluoride under stirring, heat the mixture to keep the temperature at 45-50°C, divide Add 0.80kg powdered potassium bromate in 10 batches for about 4 hours. After the addition, continue to keep warm and stir for 2 hours. Take samples for analysis until the reaction is complete, quench, extract with 3L dichloromethane, wash with sodium sulfite, remove the solvent after alkali washing, and rectify The 158-162°C / 760mmHg fraction was collected to obtain a product with a weight of 0.92kg, a purity of 99.2%, and a yield of 93.9%.

Embodiment 2

[0025] Add 6.00kg of 70% sulfuric acid into a 10L glass reactor, pass through frozen brine, control the temperature below 30°C, add 0.66kg of m-fluorobenzotrifluoride under stirring, heat the mixture to keep the temperature at 45-50°C, divide Add 1.00kg powdered potassium bromate in 10 batches for about 4 hours. After the addition, continue to keep warm and stir for 2 hours. Take samples for analysis until the reaction is complete, quench, extract with 3L dichloromethane, wash with sodium sulfite, remove the solvent after alkali washing, and rectify The 158-162°C / 760mmHg fraction was collected to obtain a product with a weight of 0.91kg, a purity of 99.0%, and a yield of 92.7%.

Embodiment 3

[0027] Add 6.00kg of 70% sulfuric acid into a 10L glass reactor, pass through frozen brine (water bath, the same below), control the temperature below 30°C, add 0.66kg of m-fluorobenzotrifluoride under stirring, and heat the mixture to keep the temperature at 30~35℃, add 0.80kg powdered potassium bromate in 10 batches, about 4 hours, continue to keep warm and stir for 2 hours after adding, take samples and analyze until the reaction is completed, quench, extract with 3L dichloromethane, wash with sodium sulfite, wash with alkali After precipitating, rectification collects 158~162 ℃ / 760mmHg distillate, obtains product weight 0.90kg, purity 99.1%, yield 91.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com