Petroleum coke desulfurizing method

A petroleum coke and removal technology, applied in the field of petroleum coke desulfurization, can solve problems such as complex operation process, achieve the effect of wide sources, cheap price, and reduce environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

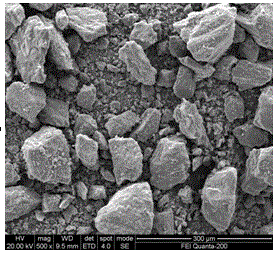

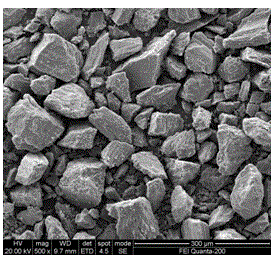

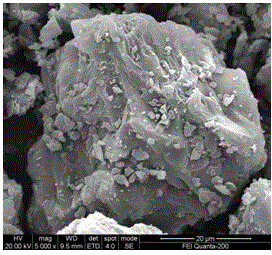

[0031] Take 5g of a domestic high-sulfur petroleum coke whose sulfur content is measured to be 6.5wt%, crush it to less than 1mm, and lay it flat in a 2×3cm flat-bottomed square porcelain boat. Then put the porcelain boat filled with petroleum coke into the furnace and heat it at a heating rate of 7°C / Min. When the temperature is raised to 600°C, heat preservation is carried out for 2 hours, and then ammonia gas is introduced (the pressure of ammonia gas in the reaction furnace is maintained at 1 atmosphere) and the temperature is raised to 800°C at 7°C / Min, and then kept at 800°C for 2 hours. Finally, the petroleum coke was taken out for sulfur measurement, and it was found that the sulfur content had dropped to 1.81wt%, and the desulfurization rate was 72.3%. Comparison of desulfurized back coke and desulfurized front coke Figure 1-4 As shown, from a microscopic point of view, the microstructure of petroleum coke does not change significantly after ammonia gas desulfuriz...

Embodiment 2

[0037] Take 5g of a medium-sulfur petroleum coke in China, whose sulfur content was measured to be 3.6wt%, crush it to less than 1mm, and lay it flat in a 2×3cm flat-bottomed square porcelain boat. Then put the porcelain boat filled with petroleum coke into the furnace and heat it at a heating rate of 7°C / Min. When the temperature is raised to 600°C, heat preservation is carried out for 2 hours, and then ammonia gas is introduced (the pressure of ammonia gas in the reaction furnace is maintained at 1 atmosphere) and the temperature is raised to 800°C at 7°C / Min, and then kept at 800°C for 2 hours. Finally, the petroleum coke was taken out for sulfur measurement, and it was found that the sulfur content had dropped to 0.98wt%, and the desulfurization rate was 72.8%.

Embodiment 3

[0039] Take 5g of a domestic low-sulfur petroleum coke whose sulfur content was measured to be 1.8wt%, crush it to less than 1 mm, and lay it flat in a 2×3cm flat-bottomed square porcelain boat. Then put the porcelain boat filled with petroleum coke into the furnace and heat it at a heating rate of 7°C / Min. When the temperature is raised to 600°C, heat preservation is carried out for 2 hours, and then ammonia gas is introduced (the pressure of ammonia gas in the reaction furnace is maintained at 1 atmosphere) and the temperature is raised to 800°C at 7°C / Min, and then kept at 800°C for 2 hours. Finally, the petroleum coke was taken out for sulfur measurement, and it was found that the sulfur content had dropped to 0.51wt%, and the desulfurization rate was 71.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com