Grate bar material of trolley of sinter machine and production method of grate bar material

A production method and technology of locomotives, applied to casting molding equipment, casting molds, cores, etc., can solve the problems of high production costs, achieve good response, improve economic benefits, and enhance market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

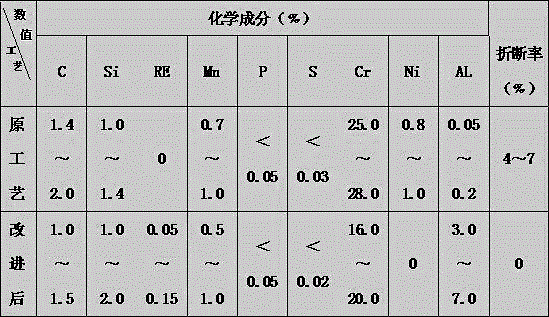

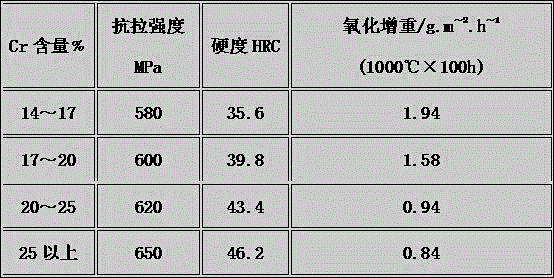

[0016] A sintering machine trolley furnace grate material, in terms of element mass percentage, its chemical composition includes C: 1% to 1.5%, Si: 1.0% to 2.0%, Cr: 16% to 20%, Al: 3.0% to 7.0%, rare earth elements: 0.05%~0.15%, Mn: 0.5%~1.0%, S<0.02%, P<0.05, the balance is Fe, and the sum of each component is 100%.

[0017] Analysis of the reasons for the failure of the grate bars: First, the grate bars are oxidized by the high temperature of the air during work, and the surface oxidizes and falls off, which makes the gap between the grate bars too large. When the gap exceeds 10mm, the grate bars fail. The second is that when the sintering machine is working without a bottoming material, there will be low-melting-point substances adhering to the grate bars at high temperatures, resulting in smaller gaps between the grate bars, poor ventilation, and failure of the grate bars. The third is that when the grate bar creeps under the action of high temperature and stress for a l...

Embodiment 2

[0053] In this embodiment, the selected chemical components include C: 1.3%, Si: 1.2%, Cr: 17%, Al: 6.0%, rare earth elements: 0.08%, Mn: 0.9%, S<0.02%, P<0.05, and the balance is Fe, the sum of each component is 100%.

[0054] The rest are the same as embodiment 1.

Embodiment 3

[0056] In this embodiment, the selected chemical components include C: 1.1%, Si: 1.8%, Cr: 19%, Al: 4.5%, rare earth elements: 0.15%, Mn: 0.6%, S<0.02%, P<0.05, and the balance is Fe, the sum of each component is 100%.

[0057] The rest are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com