A method for shortening the conduction time of the new anode current in the electrolytic cell

A technology of anode current and on-time, applied in the field of aluminum electrolysis, can solve the problems of uneven distribution of anode current, fluctuation of electrolytic cell voltage, influence of energy consumption index of electrolytic cell current efficiency index, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

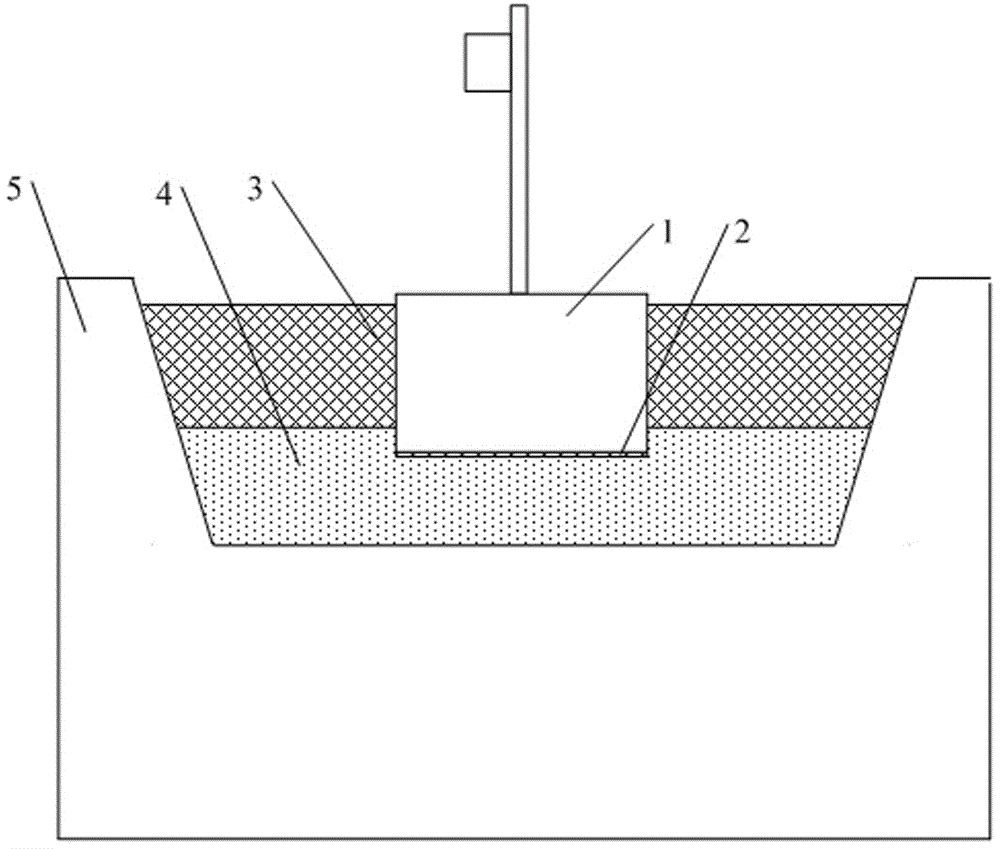

[0019] Install an aluminum plate on the bottom surface of the new anode to be replaced, and fix it by bonding. The adhesive used for bonding and fixing is epoxy resin, and the thickness of the aluminum plate is 1mm;

[0020] During the aluminum electrolysis process, when the anode is replaced, the new anode is lowered from the electrolytic cell by a crane, so that the bottom surface of the new anode and the aluminum plate pass through the electrolyte and enter the aluminum liquid. The contact time between the aluminum plate and the electrolyte is 3s, and the new anode The current is turned on, and the aluminum plate is melted; the binder melts and burns away in the process;

[0021] Under the dual effects of high-temperature aluminum liquid and the new anode's own current, the temperature of the new anode rises rapidly. When the current of the new anode rises to 50% of the normal working current, the new anode is lifted into the electrolyte by the crane to carry out normal prod...

Embodiment 2

[0023] Method is with embodiment 1, and difference is:

[0024] (1) The thickness of the aluminum plate is 3mm;

[0025] (2) The contact time between the aluminum plate and the electrolyte is 4s;

[0026] (3) When the new anode current rises to 55% of the normal operating current, lift the new anode into the electrolyte.

Embodiment 3

[0028] Method is with embodiment 1, and difference is:

[0029] (1) The aluminum plate is installed by mechanical fixing, and the thickness of the aluminum plate is 5mm;

[0030] (2) The contact time between the aluminum plate and the electrolyte is 5s;

[0031] (3) When the current of the new anode rises to 60% of the normal working current, lift the new anode into the electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com