Yarn

A technology of yarn and hemp fiber, which is applied in the field of textile materials, can solve the problems of violating the concept of green environmental protection, short product life, easy pilling and hair loss, etc., to reduce hair loss, reduce the number of cleaning or replacement, and transmit Fast heat conduction and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Yarn of the present invention is formed by blending wool and hemp fiber, and hemp fiber is jute, and its specification is 6-15D, and length is 60-160mm, and wool length is 70-130mm, and thickness is 30~38 μ m, and the weight ratio of wool and jute is 10:90.

[0013] The process flow is:

[0014] Selection of impurities - jute health treatment - blending of wool according to the content ratio of 10:90 - mixing and removing impurities - opening wool - and wool (adding antistatic agent, antifouling agent) combing - roving - spun yarn - twisting - shaping - shaking yarn, A yarn with a thickness of 15S / 1 and a twist of 145N / M is obtained.

[0015] Jute pretreatment: After the jute is sorted, add water evenly until the humidity reaches 70 degrees, and add antifouling agent and flame retardant to increase the antifouling and flame retardancy of jute.

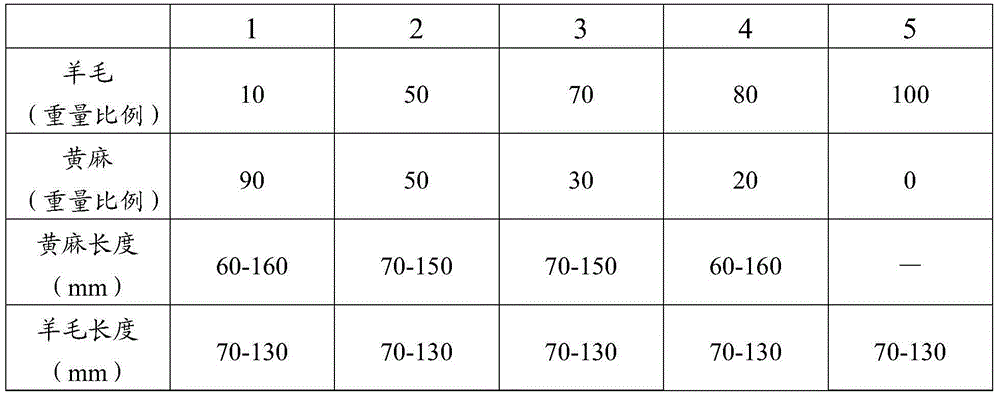

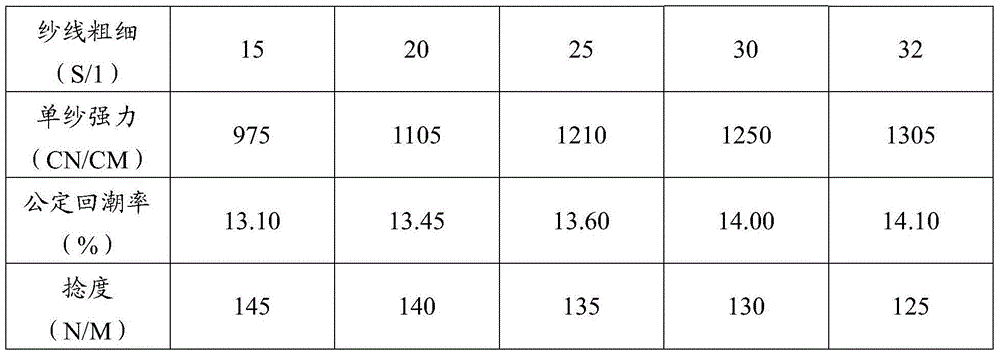

Embodiment 2-5

[0017] Except that the technological process is the same as in Example 1, the weight ratio and specifications of wool and jute are as in Table 1, and the weight ratios of wool and jute are respectively 50:50, 70:30, 80:20 and 100:0, and according to the standard GB / T3916-2013, GB9994-2008, GB / T2543.1-2001 test methods respectively test the product's single yarn strength, moisture regain and twist. The results are shown in Table 1, which meet the quality standards of textile yarns and are suitable for weaving carpets.

[0018] Table 1.

[0019]

[0020]

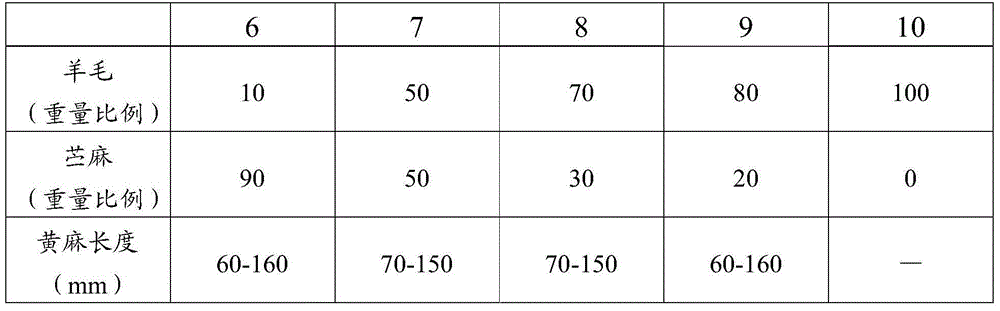

Embodiment 6

[0022] The yarn of the present invention is formed by blending wool and hemp fiber, the hemp fiber is ramie, its specification is 6-15D, the length of ramie is 60-160mm, the length of wool is 70-130mm, and the thickness is 30~38 μm, the weight ratio of wool and ramie for 10:90.

[0023] The process flow is:

[0024] Selection of impurities - ramie health care treatment - blending of wool according to the content ratio of 10:90 - mixing and removing impurities - opening wool - and wool (adding antistatic agent, antifouling agent) combing - roving - spun yarn - twisting - shaping - shaking yarn, A yarn with a thickness of 15S / 1 and a twist of 155N / M is obtained.

[0025] Ramie pretreatment: After the ramie is selected, evenly add water until the humidity reaches 70 degrees, and then add antifouling agent and flame retardant to increase the antifouling and flame retardancy of ramie.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com