Magnetic force self-sustaining electro-magnetic selector of knitting machine

A self-maintaining, knitting machine technology, used in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of waste of power consumption to maintain magnetic force, slow response speed, and insignificant effect, and achieve low power consumption, stable operation, The effect of reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

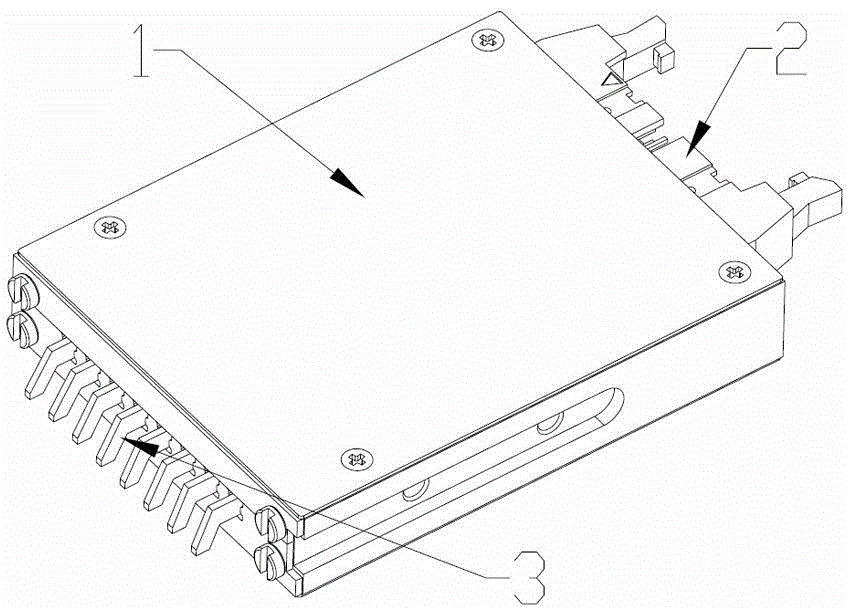

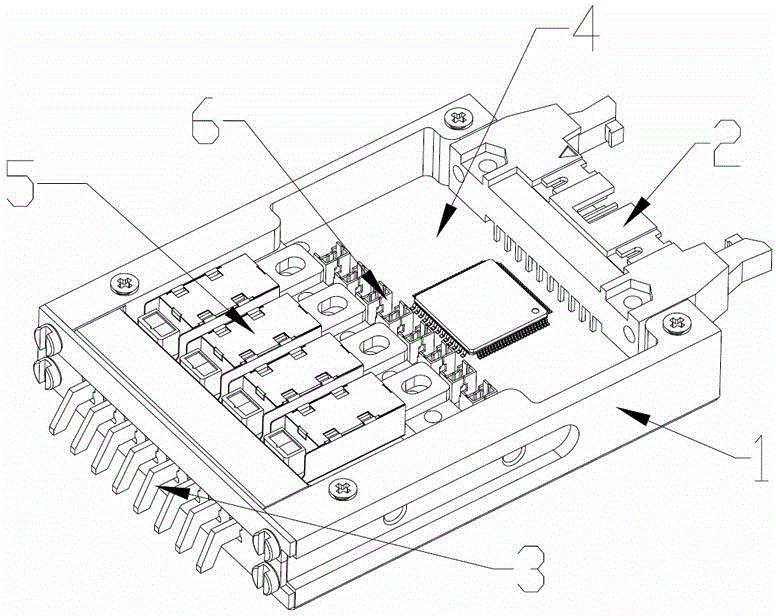

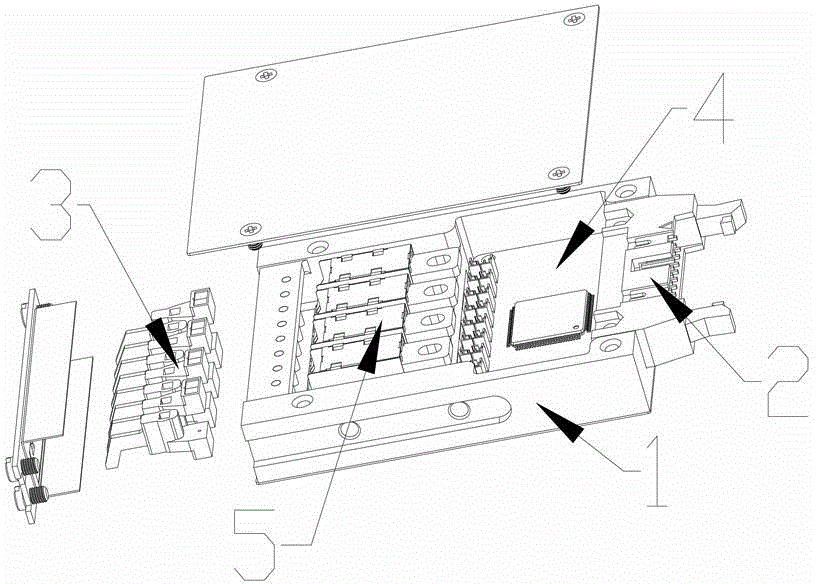

[0012] according to figure 1 , figure 2 , image 3 As shown, the present invention is based on the housing 1, the control circuit board 4, the data interface 2, the magnetic core 5, and the needle selection cutter head 3. It is characterized in that the magnetic core 5 obtains DC24V in the coil of the magnetic core. 50 mu s pulse driving signal can generate 60mT magnetic flux high remanence and low coercive force material, the coil of the magnetic core 5 is connected with the pulse output interface 6 of the control circuit board 4 through wires, and the control circuit board 4 processes the data input by the data interface 2 After knitting the needle selection signal, a positive or negative pulse signal is output from the pulse output interface 6 to the coil of the magnetic core 5, so that the magnetic strength of the magnetic core 5 is saturated, and the N or S pole magnetic field is always maintained at the front end of the magnetic core.

Embodiment 2

[0014] The difference with embodiment 1 is that the magnetic core 5 is a material with high remanence and low coercive force that can generate a magnetic flux of 105 mT when the coil of the magnetic core receives an 80 μs pulse driving signal of DC24V.

Embodiment 3

[0016] The same as embodiment 1, the difference is: the magnetic core 5 is a high remanence low coercive force material that can generate a magnetic flux of 150 mT when the coil of the magnetic core receives a 100 μs pulse driving signal of DC24V.

[0017] In the technical solution of the present invention, it is recorded that the magnetic core 5 is a material with high remanence and low coercive force that can preferably generate a magnetic flux of 60-150mT when the coil of the magnetic core obtains a DC24V 80μs pulse signal. When the device works on the knitting machine for a long time, it is the preferred solution in the general heat dissipation environment, and workers in the field can easily change the pulse voltage, pulse time, or the material of high remanence and low coercive force materials on this solution to achieve Similar effects and functions to the solutions of the present invention, such enlightening changes should be within the protection scope of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com