Low-strain dynamic monitoring device for underwater pile foundation

A low-strain, dynamic tester technology, applied in infrastructure engineering, infrastructure testing, construction, etc., can solve problems such as high labor costs, high difficulty, and restrictions on the application of low-strain dynamic testers, and achieve the goal of reducing the difficulty of positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

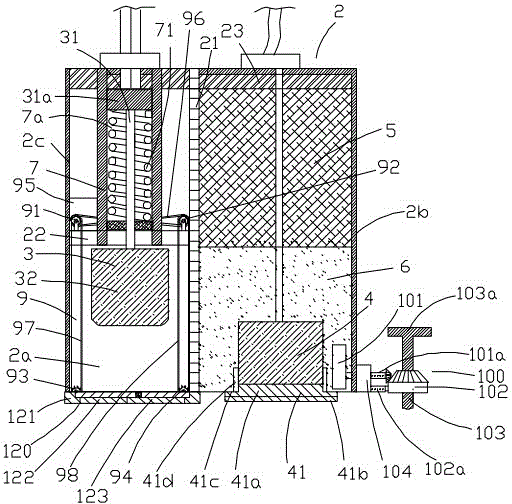

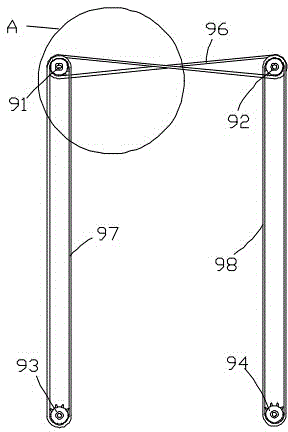

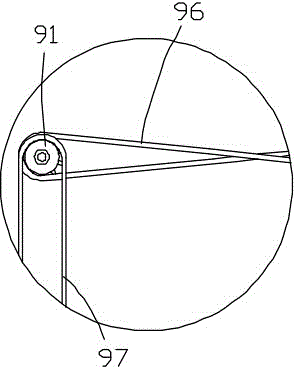

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] Figure 1 to Figure 11 Shown is the structural representation of the present invention.

[0033] The reference signs are: data processor 1, controller 11, stress wave generating and receiving device 2, left cavity 2a, right cavity 2b, housing 2c, isolation layer 21, bracket 22, adhesive layer 23, hammer 3. Hammer handle 31, rubber body 31a, hammer head 32, stress wave receiving probe 4, pressure isolation block 41, pressure isolation hard layer 41a, adhesive glue layer 41b, sealing shoulder 41c, sealing ring 41d, counterweight Block 5, damping layer 6, pushing chamber 7, pushing chamber 7a, spring 71, suction and injection device 8, high-pressure gas injection machine 81, air pump 82, opening and closing device 9, left upper transmission wheel 91, right upper transmission wheel 92, lower left transmission wheel 93, lower right transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com