Construction method of large-space multi-layer multi-curved-surface special-shaped aluminum magnesium alloy profile suspended ceiling

A technology of aluminum-magnesium alloy and construction method, applied in the direction of ceiling, building components, covering/lining, etc., can solve the problems of poor aesthetics, long construction period, slow construction speed, etc., and achieve the effect of high-efficiency technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

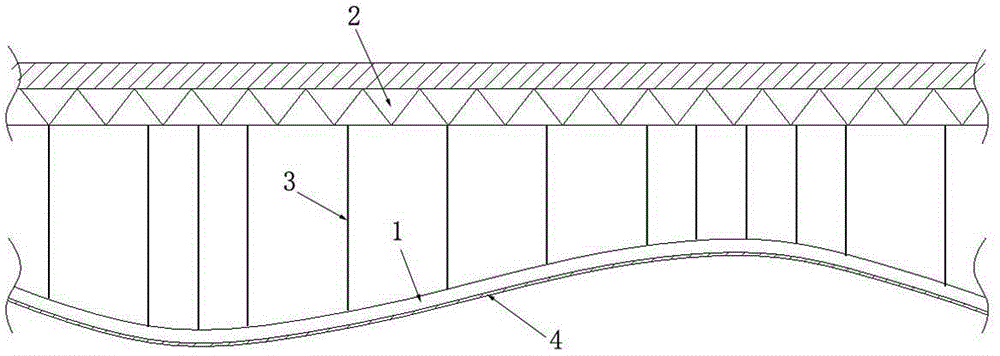

[0028] Such as figure 1 , 2 As shown, a large-space multi-level multi-curved surface special-shaped aluminum-magnesium alloy profile ceiling construction method is characterized in that it includes the following steps:

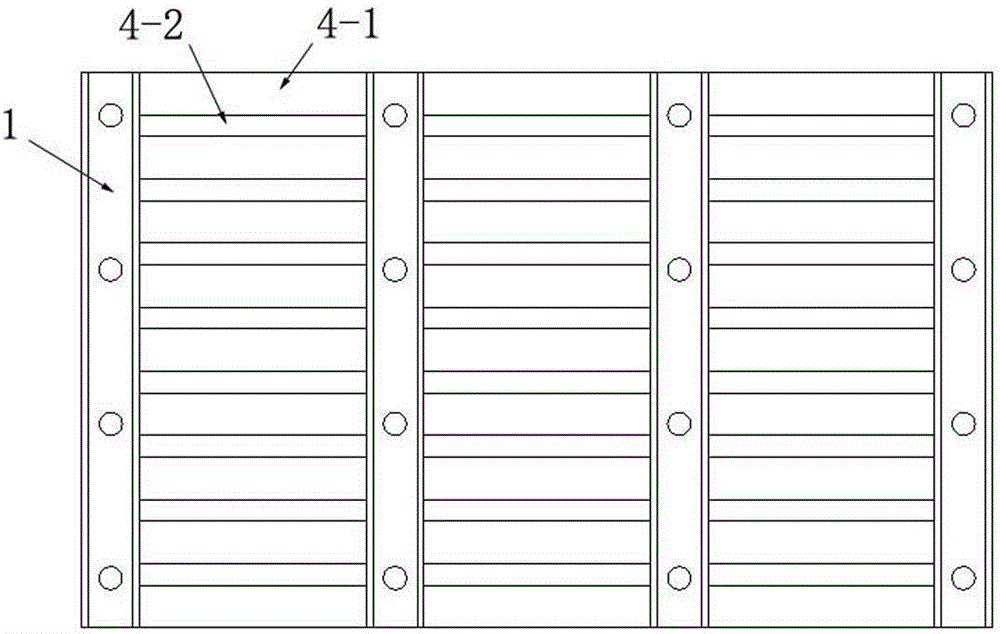

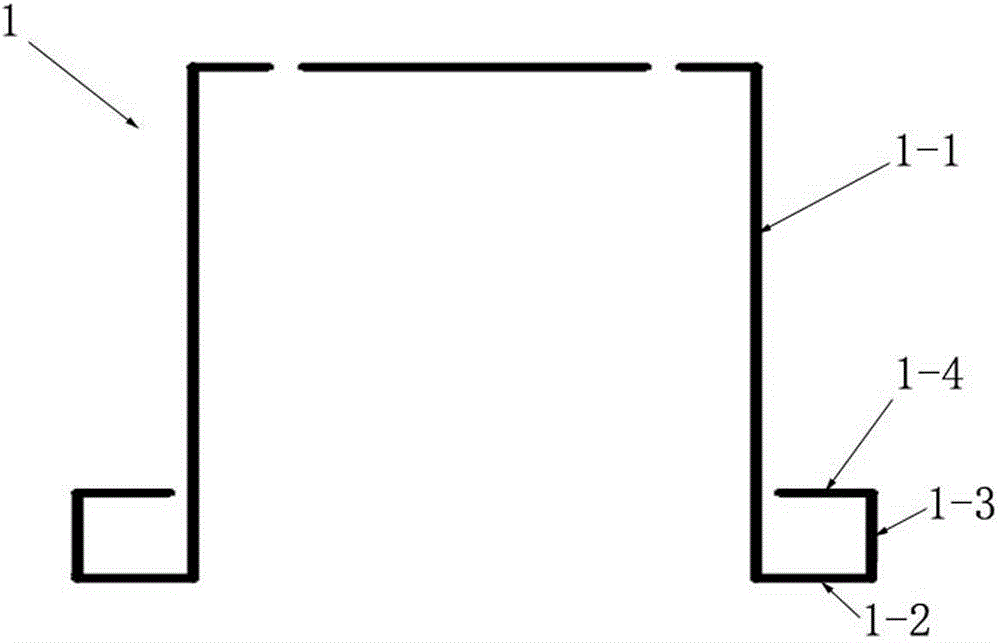

[0029] 1) Establish a measurement and control Cartesian coordinate system on the horizontal projection map of the ceiling, pop up the Cartesian coordinate system on the ground, determine the position of keel 1 according to the horizontal projection map of the ceiling, and pop up the horizontal projection ink line on the edge of keel 1 on the ground, according to the level of keel 1 The projected ink line determines the position of the suspender 3; among them, the keel 1 includes several pieces and is arranged parallel to each other, and the keel 1 is in the shape of a multi-arc curve with ups and downs in the vertical direction, so the built ceiling is als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com