Automatic air renewal system for SCR plate type catalyst calcining furnace

An automatic ventilation and calciner technology, applied in furnaces, furnace components, waste heat treatment, etc., can solve problems such as inability to effectively and accurately replenish fresh air volume, insufficient product reaction, and unbalanced pressure in the kiln. Stable pressure and atmosphere, reasonable structure, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

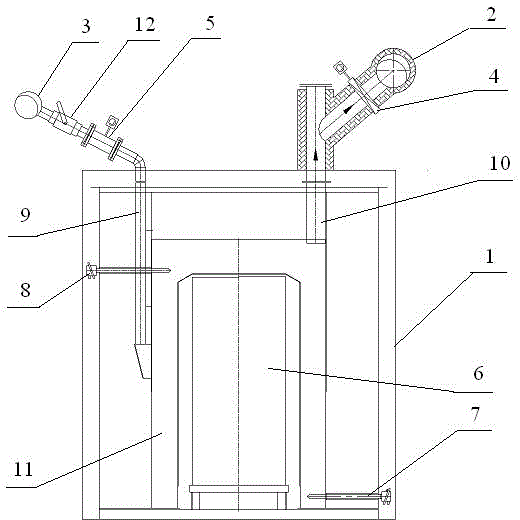

[0011] Such as figure 1 As shown, the automatic ventilation system for SCR plate catalyst calciner is composed of calciner 1, exhaust gas discharge device and fresh air replenishment device. , exhaust main pipe 2 and discharge flow detection controller 4, etc., the intake end of the exhaust branch pipe 10 communicates with the top of the circulating air duct 11 in the furnace, and the outlet end communicates with the exhaust main pipe 2 through the pipe provided with the discharge flow detection controller 4 , The pipe diameter of the exhaust branch pipe 10 is 108-250 mm. The fresh air replenishment device is composed of an air supply branch pipe 9 arranged on one side of the furnace wall, a fresh air main pipe 3 and an air supply flow detection controller 5. The outlet of the air supply branch pipe 9 communicates with the circulating air duct 11 in the furnace. The air supply flow detection controller 5 and the control valve 12 communicate with the fresh air main pipe 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com