There are two problems in using these two devices to adjust the movement of the

reticle: on the one hand, whether the two devices are mechanical or intelligent, in the process of controlling the movement of the

reticle, if the wear caused by long-term use or the device itself is not in the factory When there is a corrective error, it will bring errors to the

reticle control

Another aspect is that the mode of adjusting the reticle is adjusted one by one by the control device. The scale itself is rated, so that the adjustment reticle point is a set value, and the bullet trajectory of different firearms is Not fixed, so that the reticle cannot coincide exactly with the

impact point during

actual use, but only "approximate"

coincidenceWhen the potential target is relatively close to the firearm, the approximate

coincidence error is not very large, but at a relatively long distance, such as when it is more than 200 meters, it will bring a considerable error, making the distance between the reticle and the actual

impact point very far, so that it does not bring the result of accurate shooting

The current method of correcting this error basically relies on the shooter's own shooting experience and the

estimation of the trajectory of the bullet to make up for it. Once the shooter changes, the error cannot be made up.

[0005] 2. Optical

magnification and limitations on low-illumination environments

Limited by its structure, the maximum

magnification ratio (

Magnification Ratio) that can be achieved for civilian use is 8X, and for military use it can be 16X-20X, and only a few manufacturers can do it, and the cost is very expensive

The

reflex sight is limited by its principle and cannot achieve high

zoom ratio

The core idea of the sight is to allow the user to

zoom in on the potential target and clearly observe the details of the target that needs to be hit. Only when the target is clearly seen can the user aim at the target and bring conditions for precise strikes. However, the current optical sight is limited. Due to the limitation of the lens

magnification, it is impossible to see the target clearly in a far place, which will bring a relatively large shooting error

At the same time, the current optical sight is not self-adaptive to the

light perception of the lens in a low-light environment. It can only be solved by adding a

night vision device. In a low-light environment during the day, it is too wasteful to use a

night vision device. , and the cost is unaffordable

[0007] 3. Non-storability of ballistic data

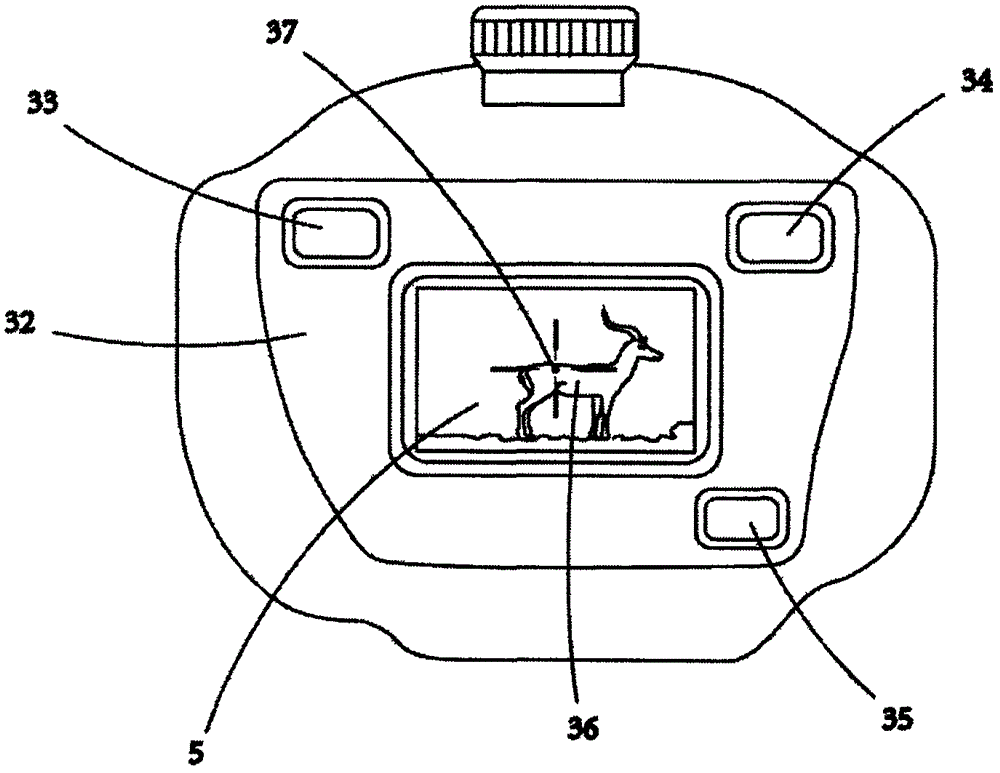

[0011] The reticle design of most existing digital sights allows the user to adjust or preset multiple reticle positions for the user to choose, and the reticle position itself cannot reflect the ballistic parameters of the firearm, which brings problems It does not fundamentally eliminate the error of the approximate

coincidence of the reticle and the impact point in the traditional optical sight, but just replaces the lens of the optical sight with the camera and display

Under such a design concept, no matter how you adjust the color, size, thickness, etc. of the reticle, the fact that there is an error between the reticle position on the display and the actual bullet impact point cannot be changed.

[0012] 2. Singleness of ballistic trajectory data

The idea of this design division is accurate, but when these digital sights store ballistic data, they only store one type of bullet impact

point data, and the number of impact points is relatively small (existing due to testing methods, ballistic error correction methods, memory capacity, etc.) limited, generally only about 20 at most), it is impossible to accurately outline the complete ballistic trajectory of the bullet. At a relatively

short distance, the shooting is often more accurate, but at a longer distance, such as after more than 500 meters, due to the impact of the bullet Due to the influence of

gravitational acceleration, the ballistic trajectory declines more severely. At this time, if the upward

angle of view of the firearm is incorrect, the shooting error will be relatively large, and the goal of accurate shooting cannot be achieved.

The singleness of stored data limits the trajectory of different people shooting the same bullet, the possibility of using different bullets on firearms, and even shooting in different environments

[0014] 3. There is a large error in the ballistic trajectory data and it cannot be corrected in real time

The starting point of this idea is very good, but the current problem is that these bullet trajectory data are often not strictly tested and verified. In the process of use, using these ballistic trajectory data as a reference scale, there will be comparison with the actual impact point big error

At the same time, the external

computer processing method itself cannot achieve real-

time processing. When the user locks the target and wants to

shoot immediately, especially for some fast-moving targets, the chance of effectively hitting is often lost in an instant. The computer, the aimer first needs to give the current target situation to the computer, and then the computer processes the result and sends the result to the aimer, so that the chance of effective hitting is lost in the middle

Therefore, it is very important for those users who have no actual shooting experience or whose psychological quality is not stable to test different kinds of bullets of firearms commonly used in the market under different environmental conditions at the same time to obtain an accurate and complete ballistic

trajectory database. It is important. At the same time, if the aimer deploys a high-speed processor and uses an

algorithm correction method to correct the ballistic parameters in real time, the impact point error at different distance points in different environments will also directly affect the results of accurate shooting.

[0016] 4. Unable to achieve

fast tracking, automatic locking and precise shooting of the target

However, the existing digital sights are still unable to do this due to various design defects.

Login to View More

Login to View More  Login to View More

Login to View More