Coordinating networking method for production plan and delivery plan of intelligent wire harness tester

A technology for production planning and shipment planning, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of high test cost, low versatility, low degree of intelligence, etc., to facilitate production and process management and optimization. Production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

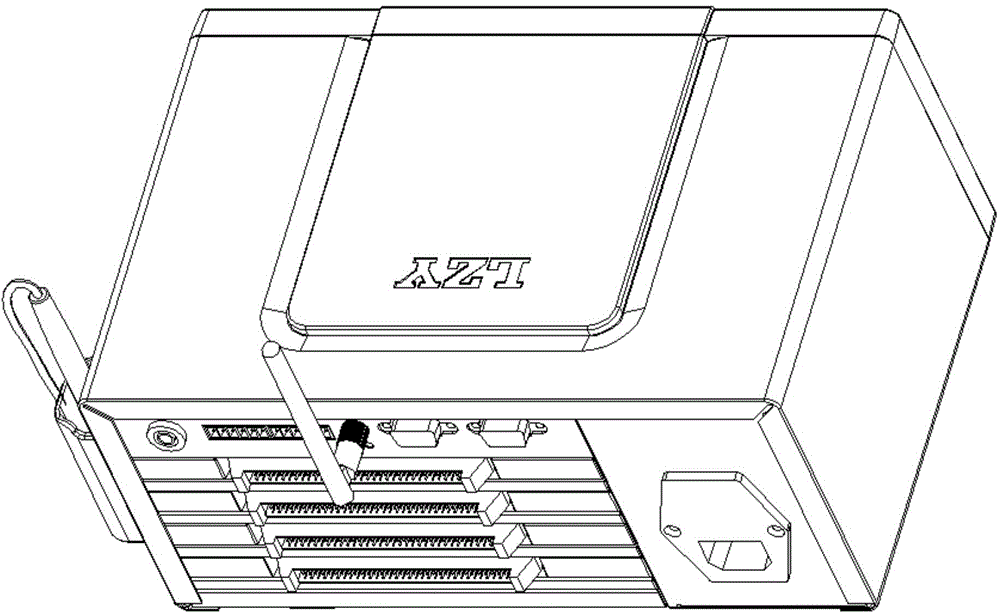

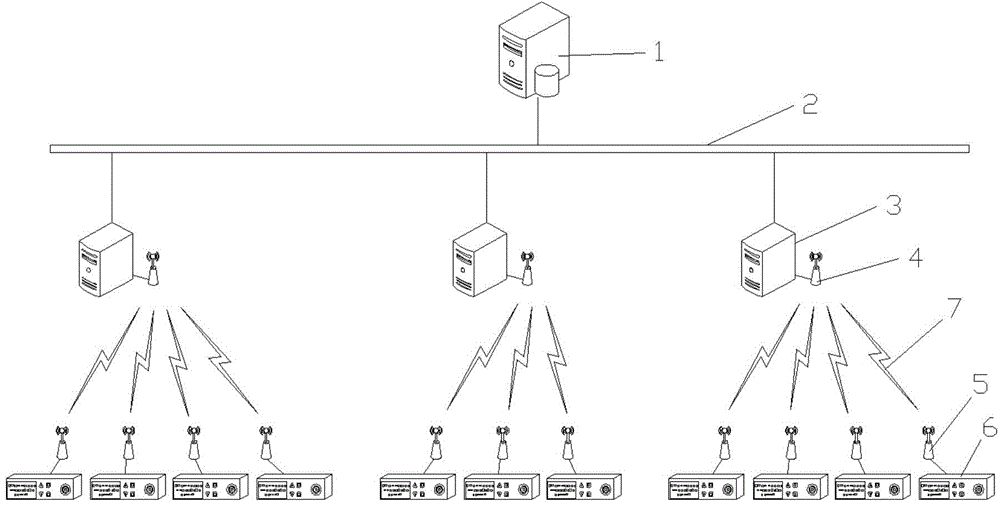

[0027] refer to figure 1 and figure 2 As shown, the coordinated networking method for the production plan and shipment plan of the wiring harness intelligent testing machine includes the main body of the wiring harness intelligent testing machine and the coordinated networking method for production and shipment. The main body of the wiring harness intelligent testing machine can automatically obtain production order data and shipment Cargo planning data, and can obtain real-time production process data, the wire harness intelligent testing machine main body is equipped with a wire harness conduction machine software function bearing module, the production and shipment coordination networking method includes a built-in intelligent analysis system, the intelligent The analysis system can optimize and coordinate the production plan an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com