ARM-based integrated polarization maintaining fiber axis positioning instrument

A polarization-maintaining optical fiber and optical fiber technology, applied in the direction of polarized optical fiber, cladding optical fiber, etc., to achieve the effect of fast and accurate auto-focus, fast computing speed, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

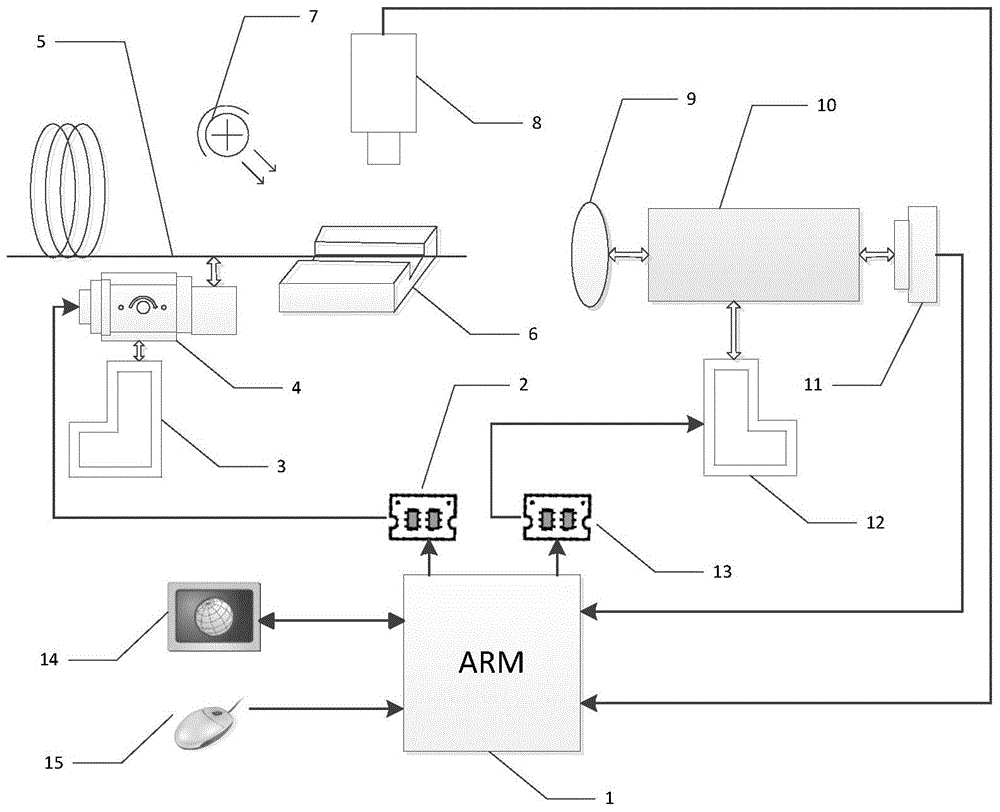

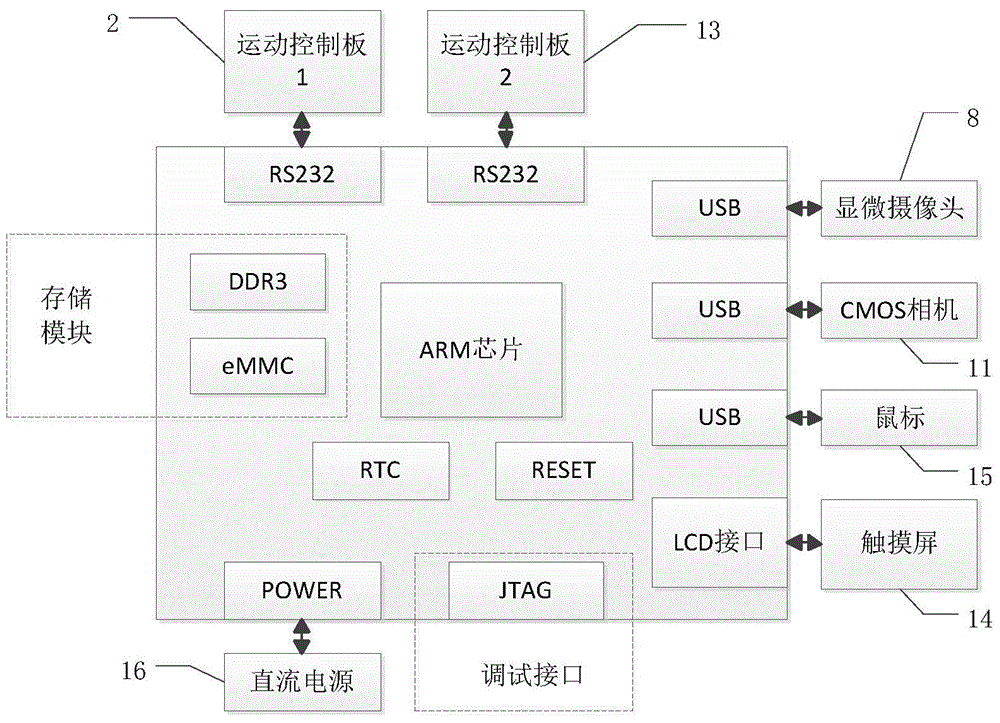

[0033] like figure 1 As shown, the ARM-based integrated polarization-maintaining fiber optic axis alignment instrument includes an image acquisition unit, an image processing and control unit 1, a motion actuator and a human-computer interaction unit.

[0034] The image acquisition unit includes a light source 7, a microscopic objective lens 9, a lens barrel 10, a CMOS industrial camera 11 and a microscopic camera 8;

[0035] The light source 7 obliquely illuminates the polarization-maintaining optical fiber 5 stripped of the coating at an angle of 30°-60° forward, the microscopic objective lens 9 and the polarization-maintaining optical fiber 5 are coaxial, and the CMOS camera 11 is connected to the microscopic objective lens 9 through the lens barrel 10. Micro camera 8 is fixed above the polarization maintaining fiber.

[0036] The motion actuator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com