Integrated pressure-resistant shell assembly

A pressure-resistant shell and component technology, which is applied in the field of nuclear reactor control and protection systems, can solve problems such as low economic benefits, leakage, and unfavorable safe operation of the nuclear power industry, and achieve the effect of low economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

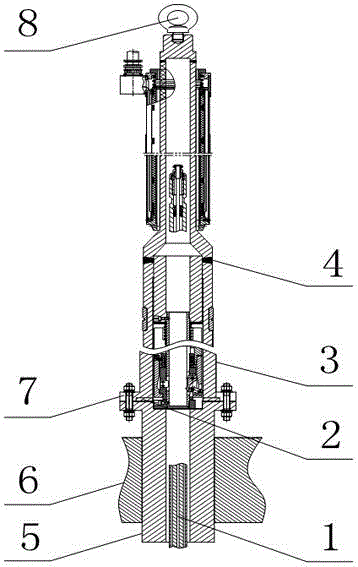

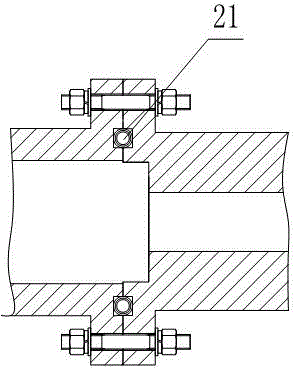

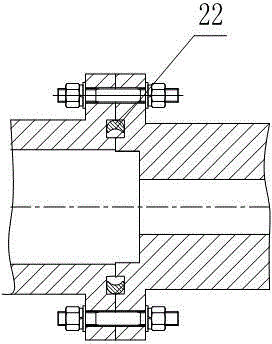

[0032] Such as Figure 1 to Figure 4 As shown, an integrated pressure-resistant shell assembly includes a pressure-resistant shell 3 and a socket 5. The pressure-resistant shell 3 is a columnar structure provided with blind holes along its axial direction. The open end of the pressure-resistant shell 3 and the One end of the pipe seat 5 is fixed with a connecting flange 7, and the two connecting flanges 7 are connected by a plurality of connecting bolts, and there is also a seal between the two connecting flanges 7 for realizing the sealing of the joint of the two connecting flanges 7. Gasket 2, the gasket 2 is a C-shaped elastic sealing ring 21 or an O-shaped elastic sealing ring 22;

[0033] The O-shaped elastic sealing ring 22 is a metal ring with a crescent-shaped cross section;

[0034] The C-shaped elastic sealing ring 21 includes an annular elastic ring 23 and at least one layer of metal wrapping layer 24 wrapped on the elastic ring 23 .

[0035] In this embodiment, t...

Embodiment 2

[0039] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 4 As shown, in order to facilitate the processing of the pressure shell 3, as a structural form of the pressure shell 3 that is easy to realize, the pressure shell 3 is a multi-section combined structure, and the sections of the pressure shell 3 are welded by V-shaped Seam 4 connected.

[0040] In order to facilitate the processing of the pressure shell 3, as another easy-to-implement structure form of the pressure shell 3, the pressure shell 3 is an integral forging or an integral structure obtained by drilling.

[0041] In order to facilitate the installation and maintenance of the control rod drive mechanism, the free end of the pressure shell 3 is also provided with lifting lugs 8 .

[0042] As a connecting bolt material with good high temperature strength and excellent thermal relaxation resistance, the material of the connecting bolt is carbon alloy steel.

[0043] In ...

Embodiment 3

[0046] This embodiment is further limited on the basis of any one of the above embodiments, such as Figure 1 to Figure 4 As shown, in order to simplify the structure of the elastic ring 23, facilitate the manufacture of the elastic ring 23, prolong the service life of the O-shaped elastic sealing ring 22, the elastic ring 23 and the metal cladding layer 24 under radiation, and reduce the residual radiation of the control rod drive mechanism during maintenance To the injury of the maintenance personnel, the materials of the O-shaped elastic sealing ring 22, the elastic ring 23 and the metal coating layer 24 are all nickel-based alloys, and the elastic ring 23 is a spring connected end to end.

[0047] In order to facilitate the manufacture of the C-shaped elastic sealing ring 22, the metal wrapping layer 24 is also provided with embedded notches 25 distributed around its circumference. The above structure facilitates inserting the elastic ring 23 from the embedded notch 25 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com