Boron injection system for second reactor shutdown system of research reactor

A technology of shutdown system and boron injection, which is applied in the field of boron injection system, can solve the problem of unsatisfactory compliance with the principle of diversity, and achieve the effects of easy manufacturing and installation, fast action and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

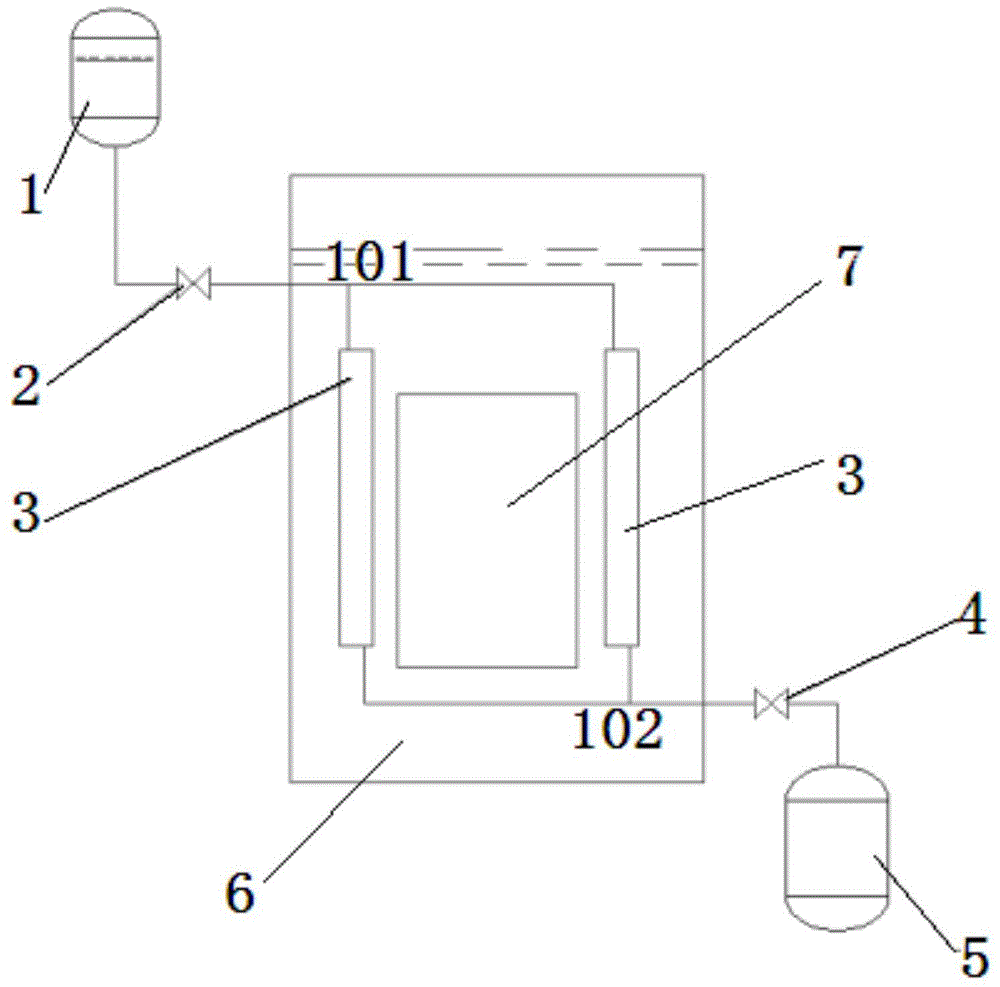

[0018] like figure 1 As shown, it is a schematic structural view of the boron injection system used for the second shutdown system of the research reactor in Embodiment 1 of the present invention. The boron injection system includes a boron liquid tank 1, an inlet valve 2, a boron injection pipe 3, an outlet valve 4 and Boron liquid recovery tank 5. The liquid outlet of the boron liquid tank 1 is connected with the liquid inlet of the boron injection pipe 3 through the first pipeline 101, and the liquid outlet of the boron injection pipe 3 is connected with the boron liquid recovery tank through the second pipeline 102 5, the inlet valve 2 is set on the first pipeline 101, and the outlet valve 4 is set on the second pipeline 102. In this embodiment, the boron injection pipe 3 has at least Two are arranged in parallel around the fuel assembly 7 in the reactor 6 . The boric acid solution meeting the concentration requirements is filled in the boron liquid tank 1 . When there ...

Embodiment 2

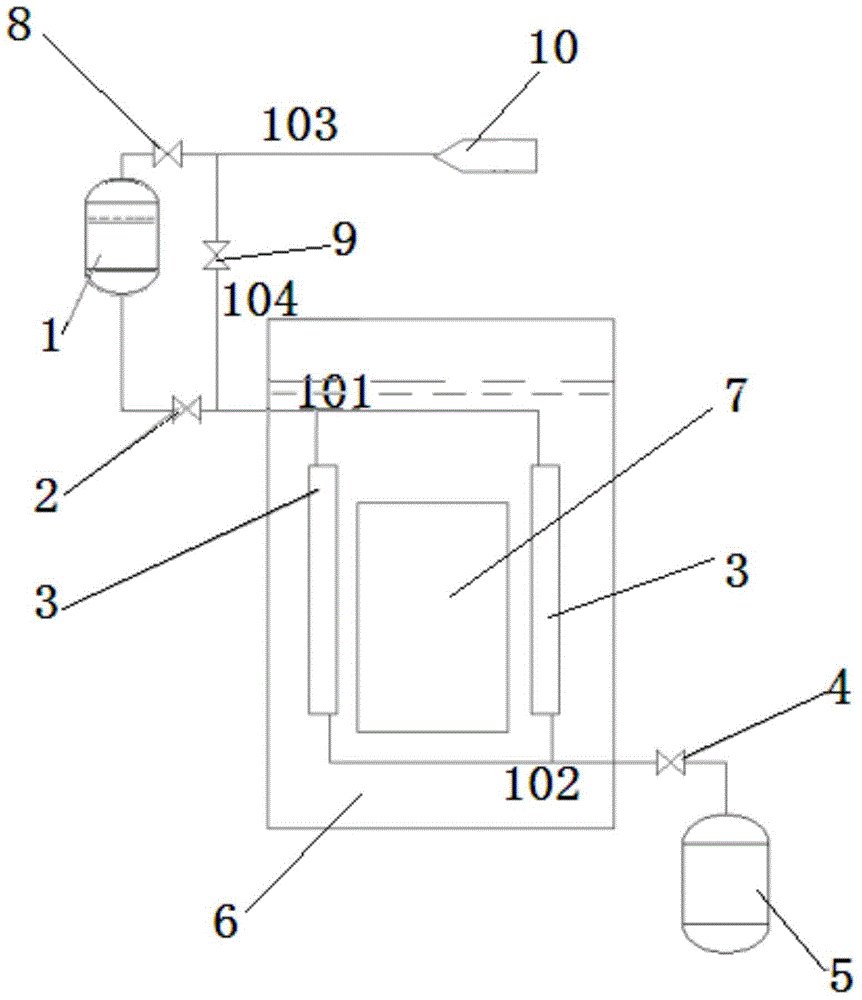

[0020] like figure 2 As shown, it is a schematic structural diagram of the boron injection system used for the second shutdown system of the research reactor in the second embodiment of the present invention. The difference between this embodiment and the first embodiment is that the boron injection system of this embodiment also includes a gas source The device 10 is used to provide pressure difference to the boron injection system. The gas outlet of the gas source device 10 is connected with the boron liquid tank 1 through a third pipeline 103, the first valve 8 is arranged on the third pipeline 103, and the third pipeline 103 and the first pipeline 101 pass through the third pipeline 103. Four pipelines 104 communicate, the second valve 9 is set on the fourth pipeline 104, the connecting end of the fourth pipeline 104 and the third pipeline 103 is located at the intake end of the first valve 8, the fourth The connecting end of the pipeline 104 and the first pipeline 101 i...

Embodiment 3

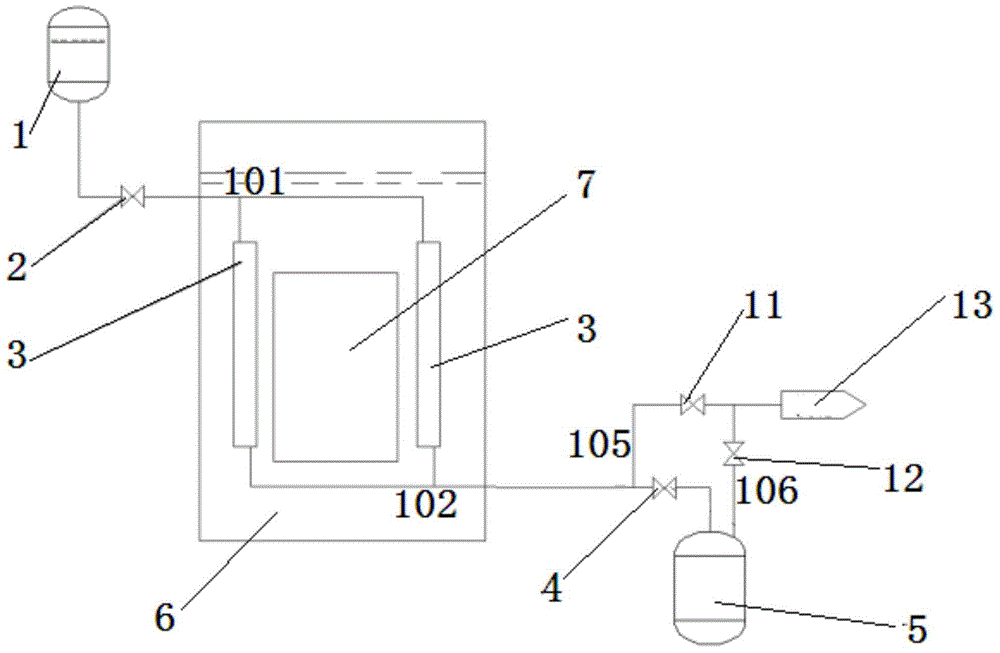

[0023] like image 3 As shown, it is a schematic structural diagram of the boron injection system used for the second shutdown system of the research reactor in the third embodiment of the present invention. The difference between this embodiment and the first embodiment is that the boron injection system of this embodiment also includes vacuum pumping The device 13 is used to provide pressure difference to the boron injection system. The vacuum device 13 is connected with the second pipeline 102 through the fifth pipeline 105, and connected with the boron liquid recovery tank 5 through the sixth pipeline 106, the third valve 11 is set on the fifth pipeline 105, and the sixth The fourth valve 12 is provided on the pipeline 106 , and the connecting end of the fifth pipeline 105 and the second pipeline 102 is located at the liquid inlet end of the outlet valve 4 .

[0024] When situations such as accidents occur and the reactor is to be shut down, the inlet valve 2 is opened. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com