Automatic reagent feeding device of combined type automatic reagent feeding sledge for pretreating raw water of power plant

An automatic dosing and pretreatment technology, applied in the direction of flocculation/sedimentation water/sewage treatment, mixer, fluid mixer, etc., to achieve the effect of preventing moisture agglomeration and high batching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

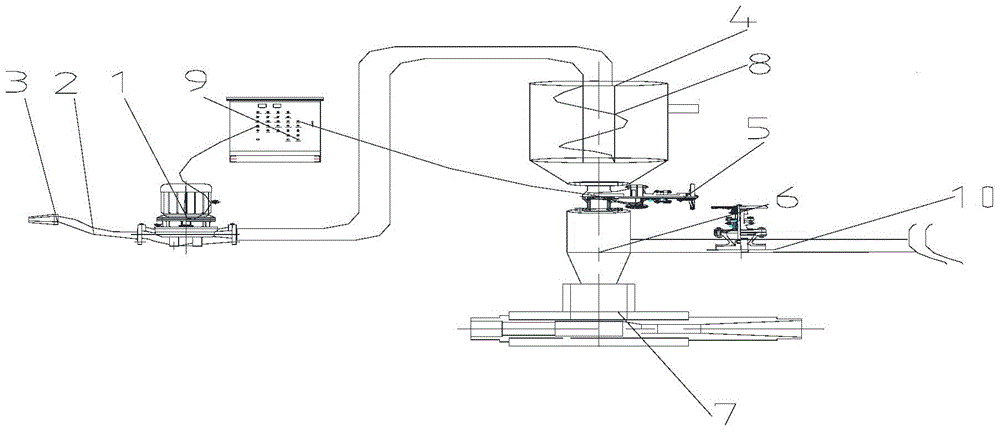

[0012] An automatic dosing device of a combined automatic dosing skid for the pretreatment of raw water in a power plant, which is composed of a vacuum suction pump (1), a hose (2), a suction head (3), a hopper (4), and a pneumatic It is composed of valve (5), pre-wetting device (6), drug atomization mixing jet (7), dry powder pushing twin-screw conveyor (8), electrical control system (9), and water supply system (10). The hopper pneumatic valve (5) is installed under the hopper (4), the pre-wetting device (6) is connected to the hopper pneumatic valve (5), and the medicament atomization mixing jet ( 7) Install under the pre-wetting unit (6). The pre-wetting device (6) is a conical chamber body. The dry powder pushing twin-screw conveyor (8) is installed in the hopper (4).

[0013] Embodiment 2 The working process of the automatic dosing device of the combined automatic dosing skid of the pretreatment of the raw water of a kind of power plant:

Embodiment 2

[0014] The powder is sucked into the hopper (4) by the vacuum suction pump (1), and is discharged under the push of the dry powder pusher twin-screw conveyor (8). The pneumatic valve (5) of the hopper is opened and enters the pre-wetting device (6). After pre-wetting, the drug atomization mixing injector (7) sprays into the pipeline and drug storage tank.

[0015] Of course, the above descriptions are not intended to limit the present invention, and the present invention is not limited to the above examples. Changes, modifications, additions or substitutions made by those skilled in the art within the scope of the present invention shall also belong to protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com