Continuous chain-type straight line drawing device

A drawing device and straight-line technology, which is applied in the field of linear continuous metal drawing equipment structure, can solve the problems such as pauses in the movement of drawing workpieces, and achieve the effects of simple equipment, low loss of production materials, and uninterrupted production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

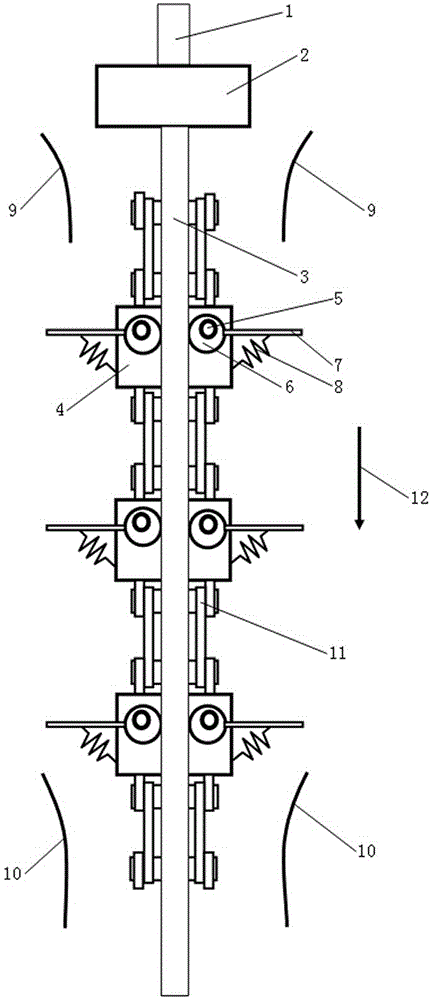

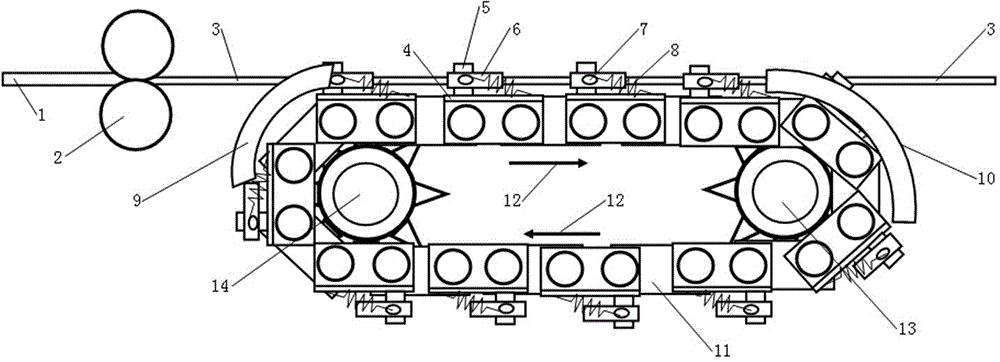

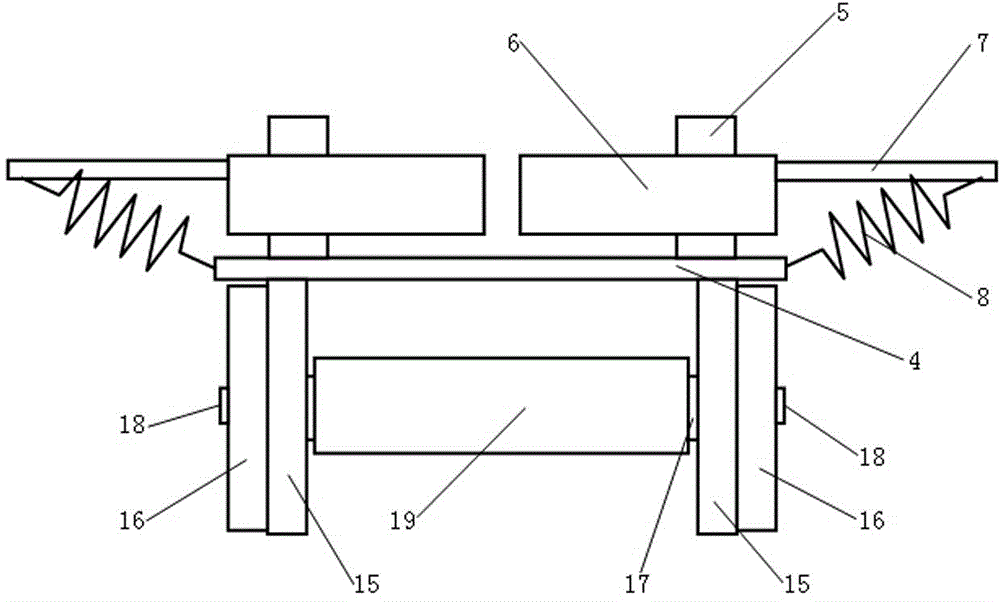

[0036] The pre-pressing head of the workpiece 1 to be drawn passes through the drawing die 2, the driving sprocket 13 rotates to drive the chain 11 to move at a constant speed and drives the driven sprocket 14 to rotate, the eccentric pressing wheel base 4, the eccentric pressing wheel axle 5, The eccentric pressing mechanism composed of the eccentric pressing wheel 6, the driving lever 7 and the spring 8 moves through the starting locking slide rail 9. When the driving lever 7 is started and the locking sliding rail 9 is pushed in the direction opposite to the chain movement direction 12, the driving lever 7 Drive the rotation of the eccentric compression wheels 6 to increase the outer edge distance of the two eccentric compression wheels 6 in the same group, and the group of eccentric compression wheels 6 moves to the same level as the drawing workpiece 3. Open to the maximum along the distance, when the group of eccentric compression wheels 6 and the drawing workpiece 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com