Numerical control electric spark deposition knife handle

A technology of EDM deposition and tool holder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

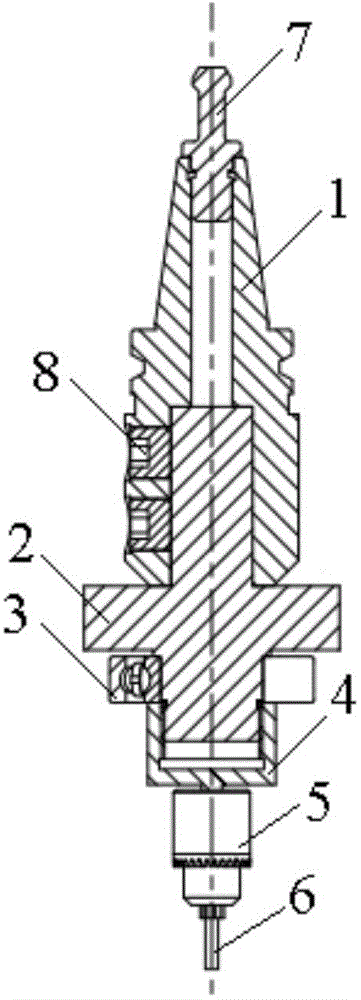

[0024] Specific embodiment 1: This embodiment is a numerically controlled electrical discharge deposition tool holder, including tool holder body 1, insulator 2, bearing 3, sleeve 4, drill chuck 5, electrode 6, pull nail 7 and set screw 8. ;

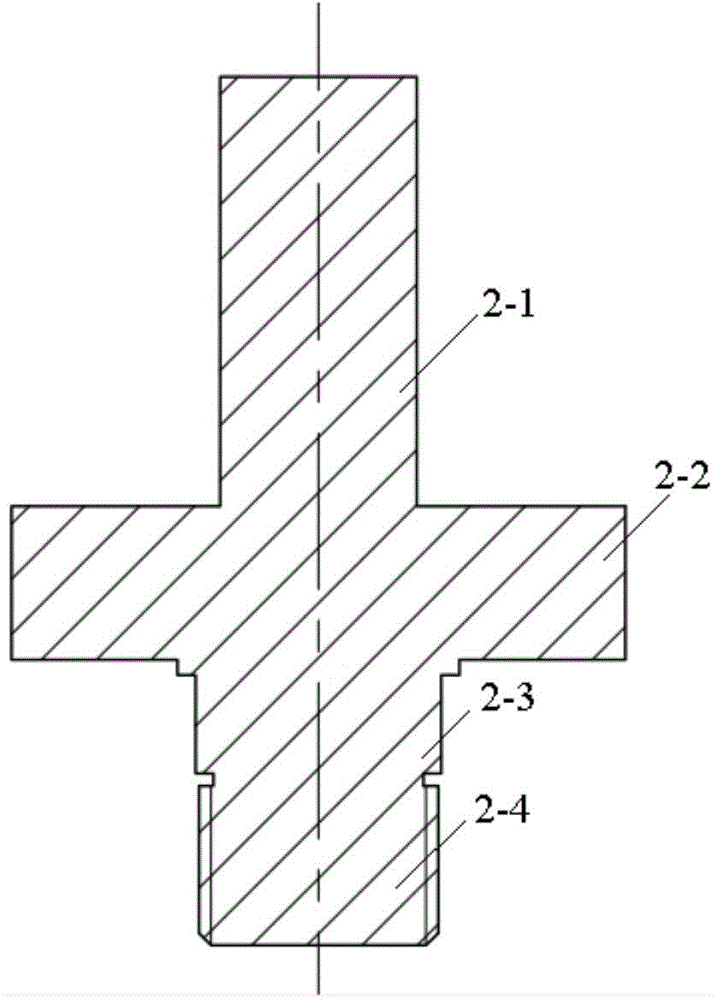

[0025] The insulator 2 includes a handle portion 2-1, a retaining ring 2-2, a bearing mounting portion 2-3 and a threaded portion 2-4;

[0026] The upper end of the shank body 1 is connected with a pull nail 7, and the shank 2-1 is inserted into the lower end of the shank body 1. The shank body 1 is provided with a set screw 8, and the set screw 8 connects the shank body 1 is fixedly connected with the shank 2-1; the inner ring of the bearing 3 is assembled to the bearing installation part 2-3, the threaded part 2-4 is threadedly connected with the sleeve 4, and the bearing 3 is fixed on the sleeve 4 and the retaining ring 2 -2; the lower end of the sleeve 4 is equipped with a drill chuck 5, and the lower end of the drill chuck 5 is equipped...

specific Embodiment approach 2

[0043] The second embodiment: The difference between this embodiment and the first embodiment is that the lower end of the sleeve 4 is connected to the drill chuck 5 through a thread or a taper hole. Others are the same as the first embodiment.

specific Embodiment approach 3

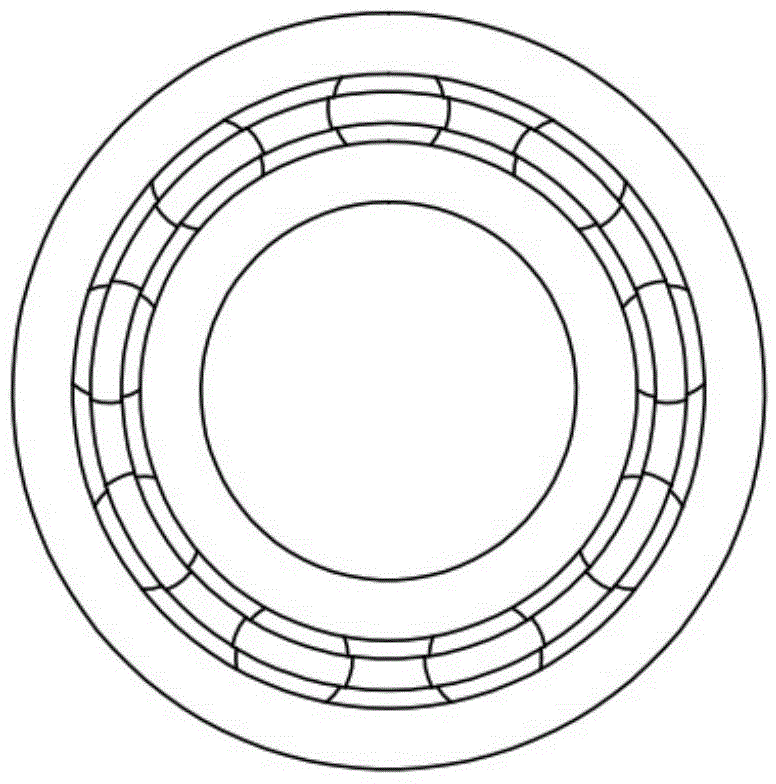

[0044] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the positive electrode of the power source of the electric spark deposition machine is welded to the outer ring of the bearing, and the negative electrode is connected to the workpiece to be deposited. Others are the same as the first or second embodiment.

[0045] In this embodiment, the positive electrode of the power source of the EDM is welded to the outer ring of the bearing, and the negative electrode is connected to the workpiece. Under the control of the numerical control program, the coating is prepared on the workpiece according to the set deposition track.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com